Method for simultaneously isolating and purifying chrysin-5-glucoside and chrysin from malus pumila

A technology for simultaneous separation of glucosides, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of single separation to obtain chrysin glycosides, the difficulty of separation of chrysin is increased, and the recovery rate of target products is low. Achieve the effect of easy industrial production, simple and easy operation, and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

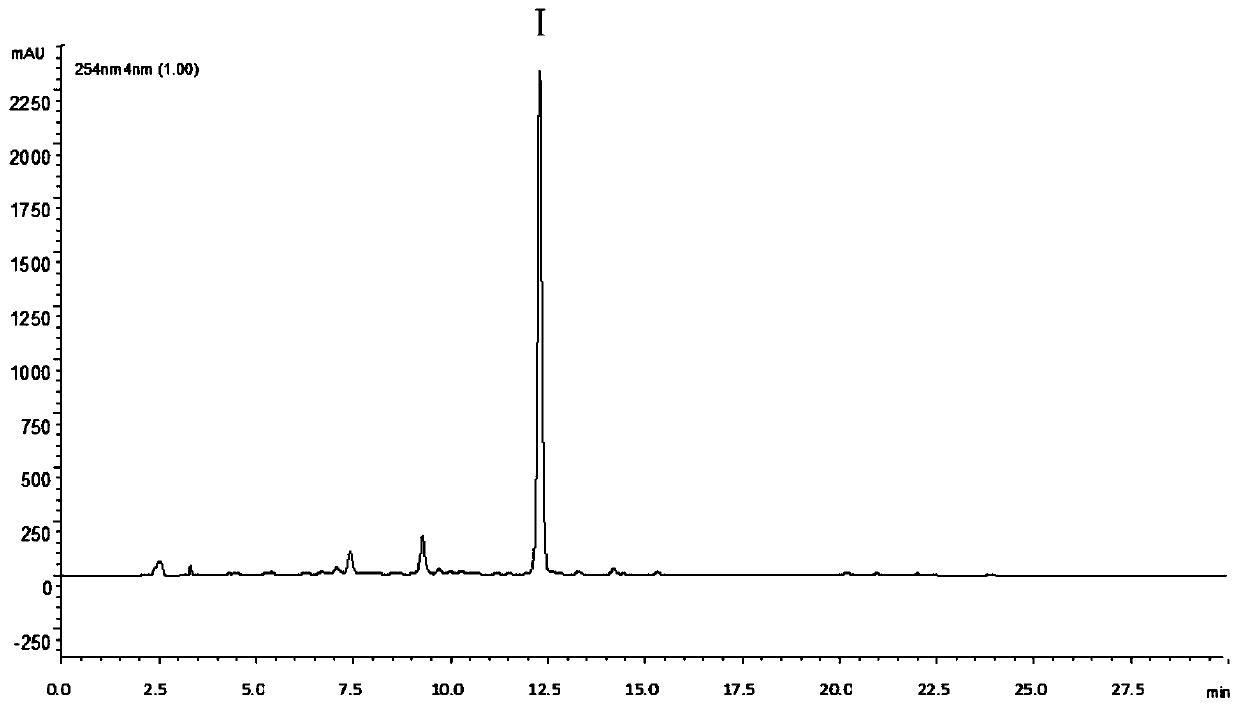

[0028] 1) Take the branches of Malus doumeri (Bois) Chevalier), dry in the sun, pulverize, pass through a 20-mesh sieve, and collect the under-sieve as the extraction raw material; the content of chrysin-5-glucoside and chrysin in the extraction raw material Detected (HLPC method, the same below), they were 3.87% and 1.05% respectively;

[0029] 2) Put 5Kg of extraction raw materials in an extraction container, add 60v / v% ethanol equivalent to 8 times the weight of the raw materials, heat up to 70°C for ultrasonic extraction (ultrasonic power is 200W) for 1.0h, filter, and repeat the above conditions for the filter residue to extract 2 times, the filtrates were combined to obtain the extract;

[0030] 3) The obtained extract is concentrated in vacuum to an extract, and the obtained extract is dissolved with 15v / v% ethanol to a saturated solution, left to stand overnight, and the supernatant is taken for later use;

[0031] 4) Equilibrate the macroporous adsorption resin colum...

Embodiment 2

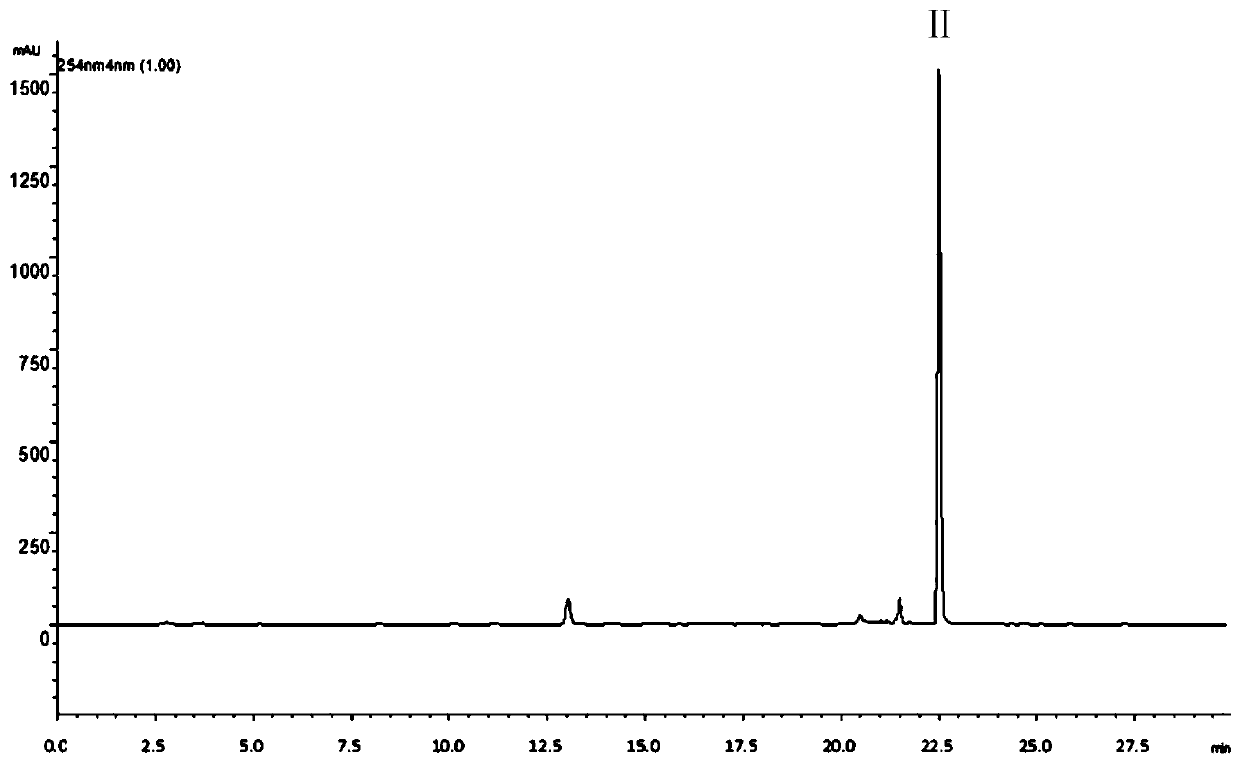

[0053] 1) Get the leaves of Malus doumeri (Bois) Chevalier), dry in the sun, pulverize, pass through a 20-mesh sieve, and collect the under-sieve as the extraction raw material; the content of chrysin-5-glucoside and chrysin in the extraction raw material is analyzed. Detection (HLPC method, the same below), respectively 4.43% and 1.07%;

[0054] 2) Put 5Kg of extraction raw materials in an extraction container, add 80v / v% methanol equivalent to 6 times the weight of the raw materials, heat up to 60°C for reflux extraction for 2.0h, filter, and repeat the extraction of the filter residue twice under the above conditions, and combine the filtrates to obtain Extraction solution;

[0055] 3) The obtained extract is concentrated in vacuum to an extract, and the obtained extract is dissolved with 10v / v% methanol to a saturated solution, left to stand overnight, and the supernatant is taken for later use;

[0056] 4) First equilibrate the macroporous adsorption resin column (resin ...

Embodiment 3

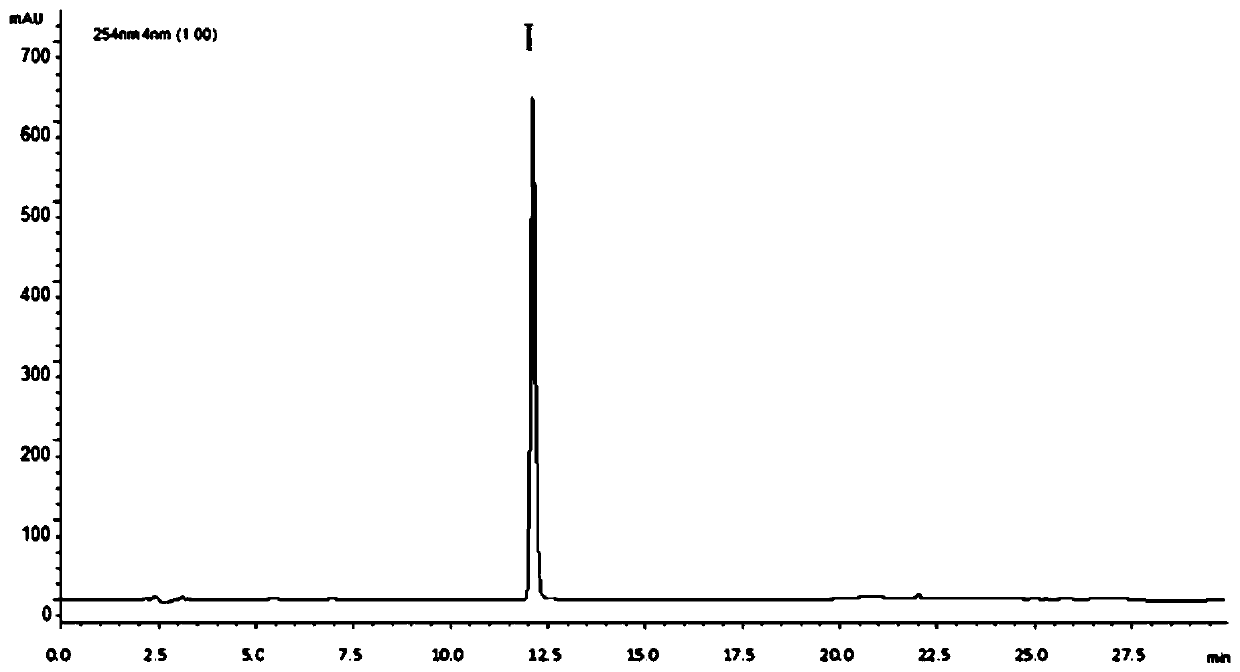

[0060] 1) Take the branches of Malus melliana (Hand.-Mazz.) Rehder), dry in the sun, pulverize, pass through a 40-mesh sieve, and collect the under-sieve as the extraction raw material; Chrysin-5-glucoside in the extraction raw material and chrysin content were detected, which were 3.34% and 1.21% respectively;

[0061] 2) Put 5Kg of extraction raw materials in an extraction container, add 80v / v% ethanol equivalent to 5 times the weight of the raw materials, reflux extraction for 2.0h, filter, repeat the extraction of the filter residue under the above conditions once, and combine the filtrates to obtain the extract;

[0062] 3) The obtained extract is concentrated in vacuum to an extract, and the obtained extract is dissolved with 25v / v% ethanol to a saturated solution, left to stand overnight, and the supernatant is taken for later use;

[0063] 4) Equilibrate the macroporous adsorption resin column (resin model is AB-8) with 3 times the column volume and 25v / v% ethanol firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com