Method for preparing germanium chloride by microwave one-step method from tannin germanium slag

A germanium chloride and germanium slag technology is applied in the fields of metallurgy and energy, can solve the problems of high energy consumption, long time, low impurity content of germanium tetrachloride, etc., and achieves reduced process energy consumption, easy operation and good wave absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

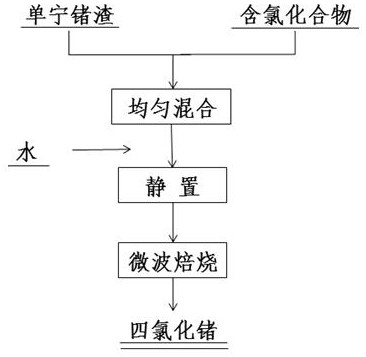

[0018] Embodiment 1: a kind of method for preparing germanium chloride by microwave one-step method of tannin germanium slag (see figure 1 ),Specific steps are as follows:

[0019] (1) Mix tannin germanium slag and chlorine-containing compound (ammonium chloride) to obtain mixture A, add water to mixture A, mix evenly and let it stand for 5 minutes to obtain mixture B; the tannin germanium slag is obtained through the lead-zinc smelting process The residue is obtained by leaching germanium-containing zinc oxide fumes obtained by volatilization in a fuming furnace, and precipitating germanium with tannic acid. The content of Zn is 5%, the content of S is 5%, the content of Ge is 0.5%, and the content of other impurity elements is 5%; The mass ratio of germanium tannin slag and chlorine-containing compound (ammonium chloride) is 5:1, and the liquid-solid ratio mL:g of water to mixture A is 1:3;

[0020] (2) Step (1) The mixture B is subjected to microwave roasting, and the roas...

Embodiment 2

[0024] Embodiment 2: a kind of method that tannin germanium slag microwave one-step method prepares germanium chloride (see figure 1 ),Specific steps are as follows:

[0025] (1) Mix tannin germanium slag and chlorine-containing compound (commercially available hydrochloric acid) to obtain mixture A, add water to mixture A, mix evenly and let it stand for 20 minutes to obtain mixture B; the tannin germanium slag is obtained through the lead-zinc smelting process The residue is obtained by leaching germanium-containing zinc oxide dust obtained by volatilization in a fuming furnace, and precipitating germanium with tannic acid. The content of Zn is 15%, the content of S is 10%, the content of Ge is 2.0%, and the content of other impurity elements is 15%; The mass ratio of germanium tannin slag and chlorine-containing compound (commercially available hydrochloric acid) is 1:1, and the liquid-solid ratio mL:g of water to mixture A is 1:1;

[0026] (2) Step (1) The mixture B is su...

Embodiment 3

[0029] Embodiment 3: a kind of method that tannin germanium slag microwave one-step method prepares germanium chloride (see figure 1 ),Specific steps are as follows:

[0030] (1) Mix tannin germanium slag and chlorine-containing compound (calcium chloride) to obtain mixture A, add water to mixture A, mix evenly and let it stand for 30 minutes to obtain mixture B; the tannin germanium slag is obtained through the lead-zinc smelting process The residue is obtained by leaching germanium-containing zinc oxide fumes obtained by volatilization in a fuming furnace, and precipitating germanium with tannic acid. The content of Zn is 30%, the content of S is 20%, the content of Ge is 5%, and the content of other impurity elements is 30%; The mass ratio of germanium tannin slag and chlorine-containing compound (calcium chloride) is 1:5, and the liquid-solid ratio mL:g of water to mixture A is 3:1;

[0031] (2) Step (1) The mixture B is subjected to microwave roasting, and the roasting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com