Preparation method of (100) preferred orientation PMN-PZT/PZT heterostructure film

A heterostructure, preferential orientation technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, device material selection, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of long preparation cycle, cost Expensive, unfavorable piezoelectric film production and application, etc., to achieve the effect of improving structural inhomogeneity, improving dielectric properties, and improving dielectric and ferroelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

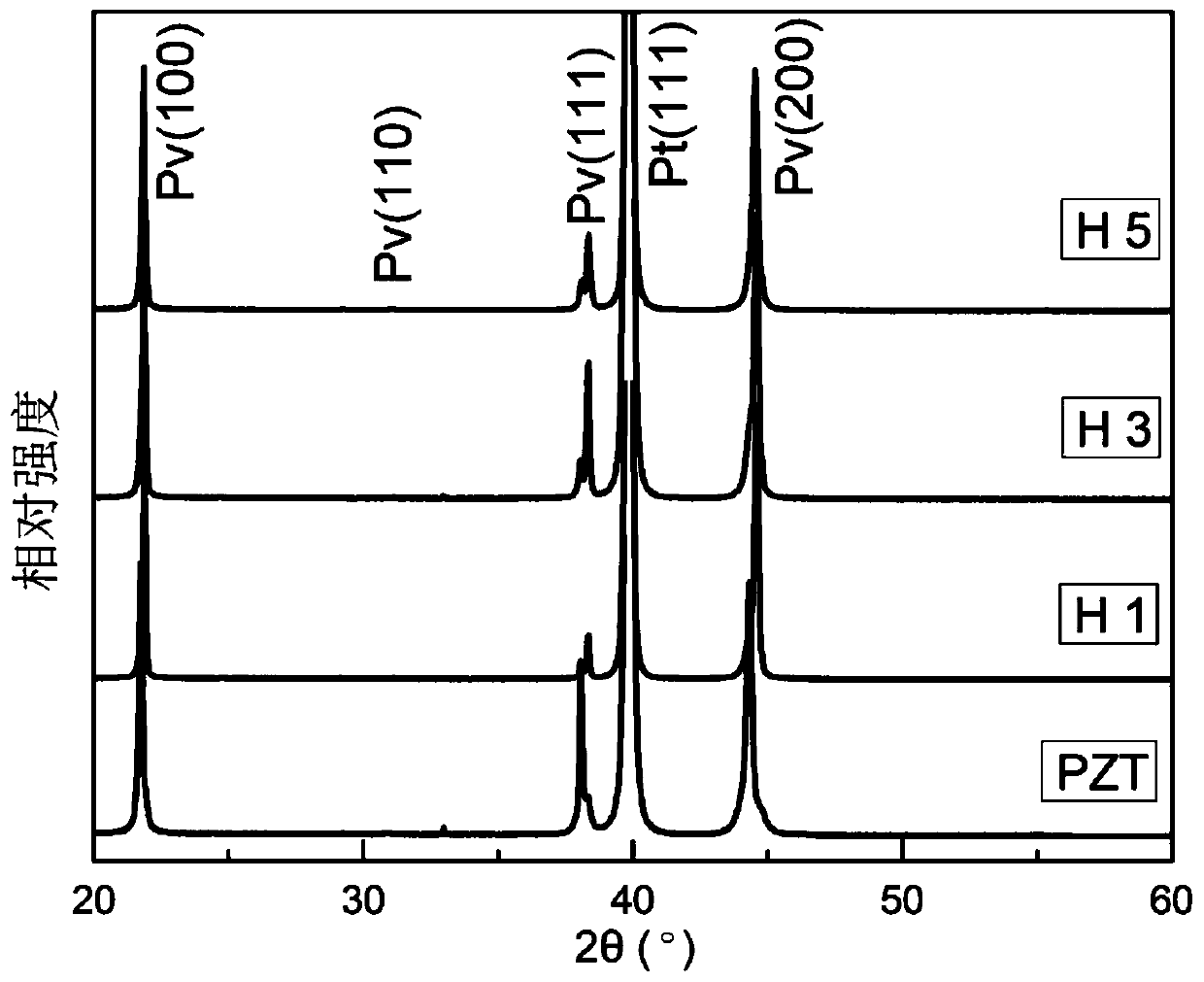

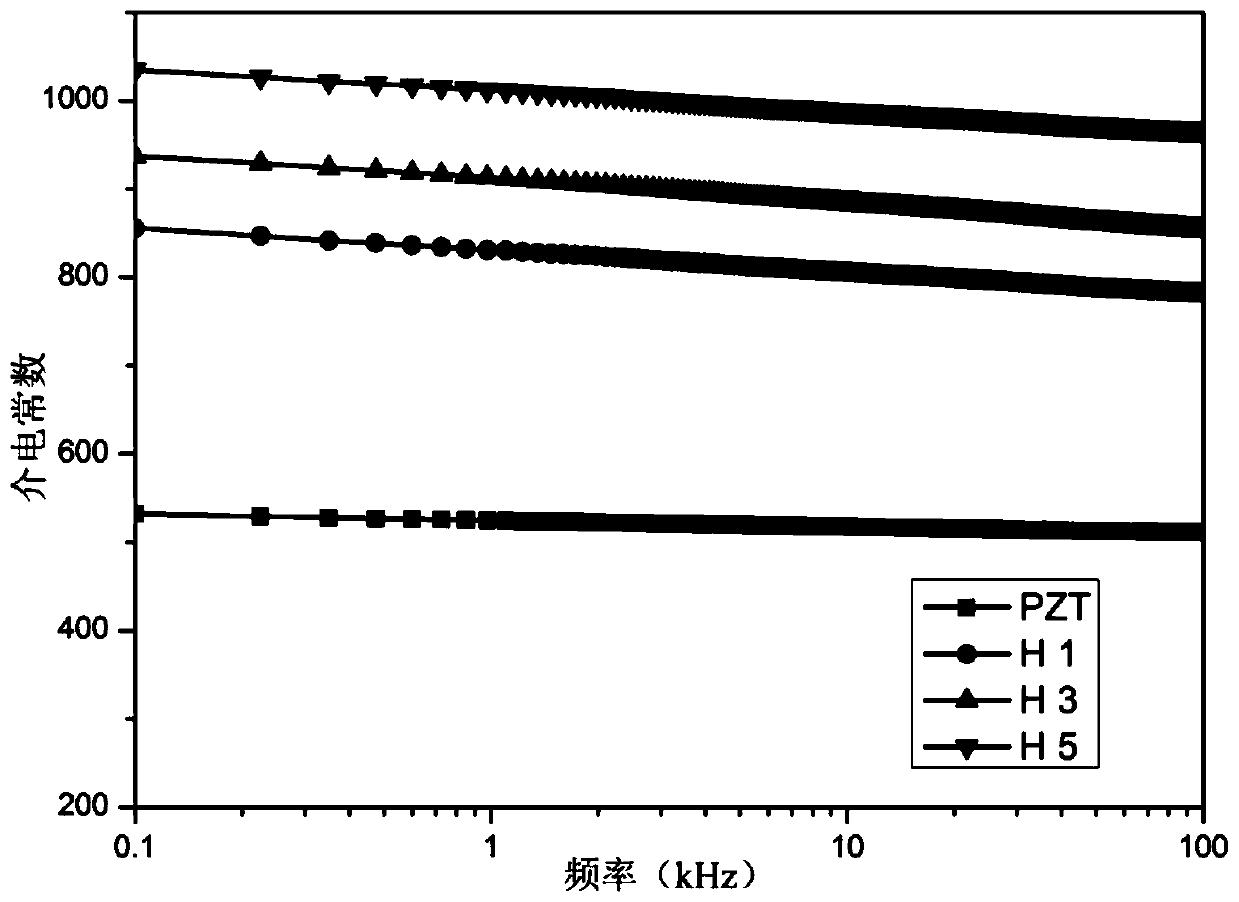

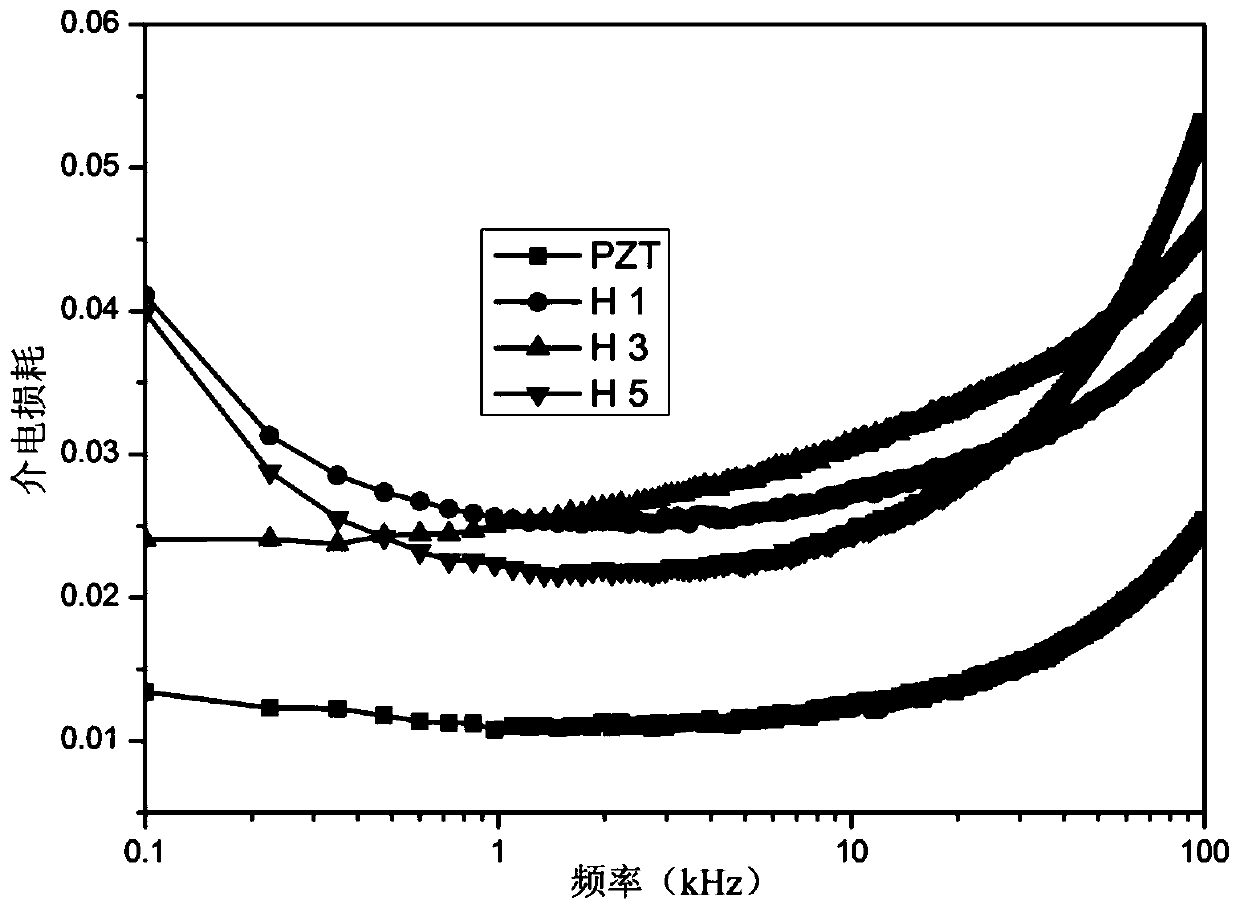

[0027] This embodiment provides a method for preparing a PMN-PZT / PZT heterostructure thin film (H1) with a heterointerface number of 1, and the specific steps are:

[0028] S101, preparing the lead zirconate titanate seed layer:

[0029] According to the excess of 20% lead element in the seed layer, first dissolve 2.9mL tetrabutyl titanate in 1.6mL acetylacetone, then raise the temperature to 40°C and keep it warm for 1 hour; then add 4.02g zirconium nitrate and 10.51g lead acetate in sequence and 30mL of ethylene glycol methyl ether, fully dissolved and stirred evenly, then heated up to 80°C, and kept warm for 1 hour; then added 1.8mL formamide, stirred well, then cooled down to 40°C, kept warm for 1 hour; finally added 11mL with a mass content of 36% acetic acid solution is kept warm for 1 hour to obtain a lead zirconate titanate seed layer precursor solution with a concentration of about 0.35 mol / L, which satisfies the stoichiometry.

[0030] The above-mentioned lead zirco...

Embodiment 2

[0037] This embodiment provides a method for preparing a PMN-PZT / PZT heterostructure thin film (H3) with a heterointerface number of 3. The specific steps are:

[0038] S201. Prepare the lead zirconate titanate seed layer:

[0039] Dosing according to 20% excess lead element in the seed layer, first dissolve 2.9mL tetrabutyl titanate in 1.9mL acetylacetone, then raise the temperature to 40°C and keep it warm for 1 hour; then add 4.02g of zirconium nitrate and 10.51g of lead acetate in sequence and 30mL of ethylene glycol methyl ether, fully dissolved and stirred evenly, then heated up to 80°C, and kept warm for 1 hour; then added 2.1mL formamide, stirred well, then cooled down to 40°C, kept warm for 1 hour; finally added 11mL with a mass content of 36% acetic acid solution is kept warm for 1 hour to obtain a lead zirconate titanate seed layer precursor solution with a concentration of about 0.35 mol / L, which satisfies the stoichiometry.

[0040] The above-mentioned lead zirco...

Embodiment 3

[0046] This embodiment provides a method for preparing a PMN-PZT / PZT heterostructure thin film (H5) with 5 heterointerfaces. The specific steps are:

[0047] S301. Prepare the lead zirconate titanate seed layer:

[0048] Dosing according to 20% excess lead element in the seed layer, first dissolve 2.9mL tetrabutyl titanate in 1.1mL acetylacetone, then raise the temperature to 40°C and keep it warm for 1 hour; then add 4.02g of zirconium nitrate and 10.51g of lead acetate in sequence and 30mL of ethylene glycol methyl ether, fully dissolved and stirred evenly, then heated up to 80°C, and kept warm for 1 hour; then added 1.5mL formamide, stirred well, then cooled down to 40°C, kept warm for 1 hour; finally added 11mL with a mass content of 36% acetic acid solution is kept warm for 1 hour to obtain a lead zirconate titanate seed layer precursor solution with a concentration of about 0.35 mol / L, which satisfies the stoichiometry.

[0049] The above-mentioned lead zirconate titana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com