Sodium titanium phosphate surface modified P2-type manganese-based sodium ion battery positive electrode material with Nasicon structure and preparation method thereof

A sodium-ion battery and positive electrode material technology, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., to achieve low cost, good reproducibility, and reduce side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

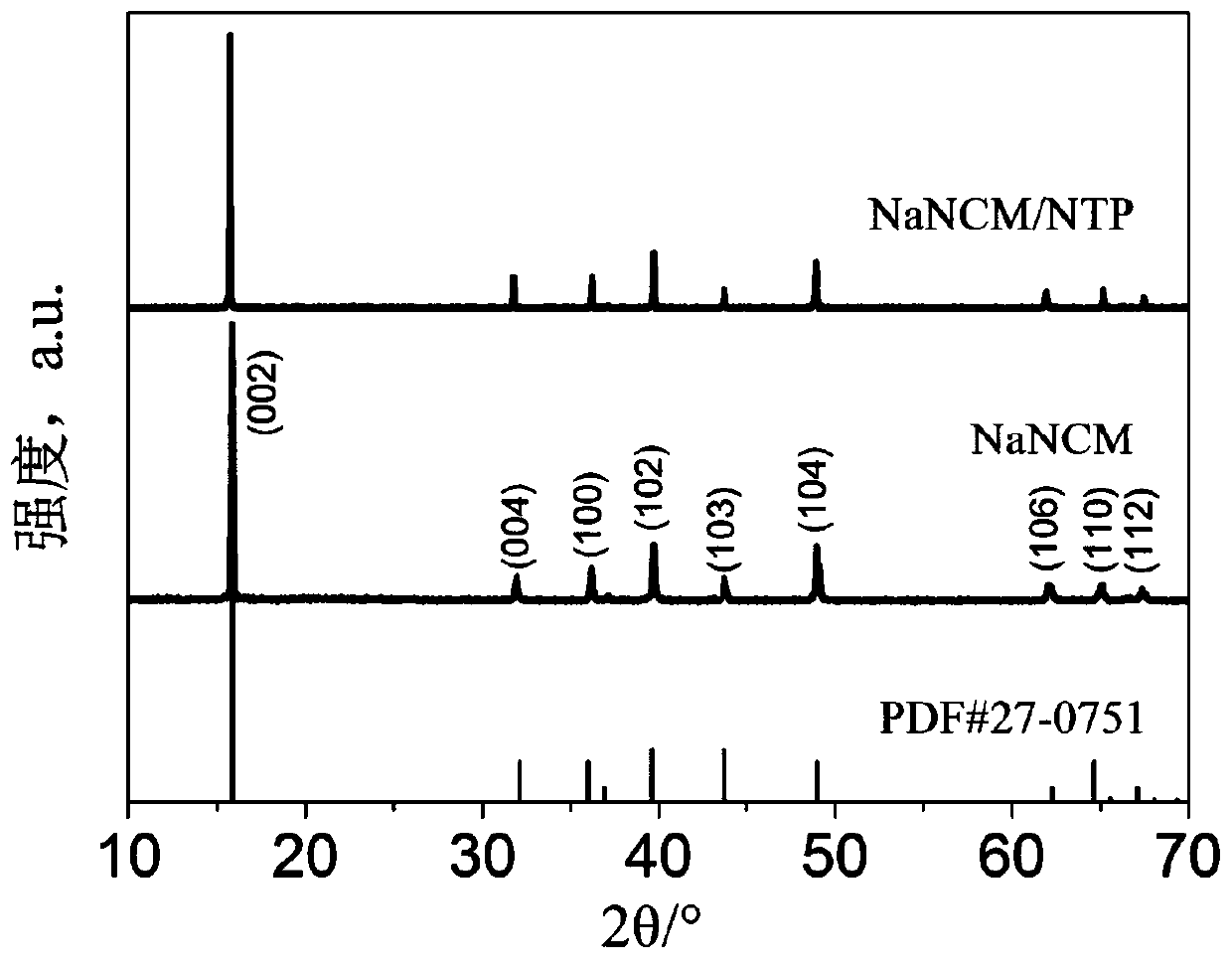

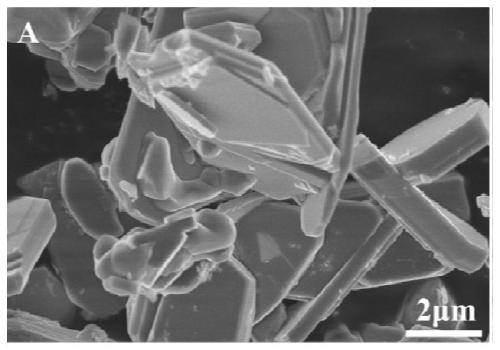

[0031] (1) According to the synthesis of 10g of Na 0.65 Ni 0.16 co 0.14 mn 0.7 o 2 The molar ratio of Mn, Ni and Co elements in the solution is weighed manganese nitrate, nickel nitrate and cobalt nitrate and dissolved in 200mL deionized water, adding sodium nitrate in excess of 1mol%, stirring constantly, after the metal salt is dissolved, weigh 1g of citric acid Add it to the solution, stir and evaporate to dryness at 80°C to obtain a gel substance.

[0032] (2) Vacuum-dry the gel obtained in step (1) at 80°C, crush it, pre-calcine at 400°C for 4 hours in an air atmosphere, then sinter at 850°C for 12 hours, and cool to room temperature to obtain the pure phase P2 NaNCM is a positive electrode material for manganese-based sodium-ion batteries.

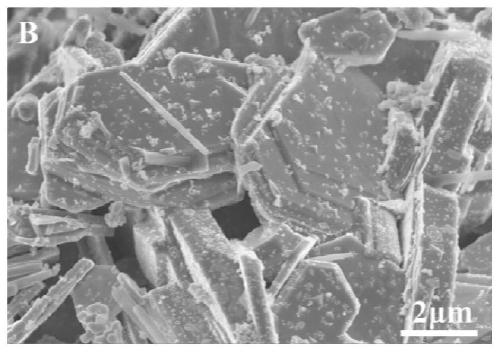

[0033] (3) Weigh 5g of the pure-phase product NaNCM and disperse it in 50mL of absolute ethanol, stir for 1 hour to obtain a uniformly dispersed suspension, and then 2 (PO 4 ) 3 The mass ratio to NaNCM is 0.0005:1. Weigh buty...

Embodiment 2

[0037] (1) According to the synthesis of 10g of Na 2 / 3 Ni 1 / 3 mn 2 / 3 o 2 In the mol ratio of Mn, Ni element, take manganese acetate, nickel acetate and dissolve in 200mL deionized water, add sodium acetate excessive 3mol%, keep stirring, after the step metal salt dissolves, take by weighing 2g of citric acid and add in the solution, Stir and evaporate to dryness at 90°C to obtain a gel substance.

[0038] (2) Vacuum-dry the gel obtained in step (1) at 90°C, crush it, pre-calcine at 500°C for 5 hours in an air atmosphere, then sinter at 925°C for 15 hours, and cool to room temperature to obtain the pure phase P2 Manganese-based sodium-ion battery cathode material NaNM.

[0039] (3) Weigh 5g of the pure-phase product NaNM and disperse it in 20mL of acetone, stir for 2 hours to obtain a uniformly dispersed suspension, and then 2 (PO 4 ) 3 The mass ratio of NaNM to NaNM is 0.1:1. Weigh titanium isopropoxide and add it to the suspension, then use deionized water to prepare d...

Embodiment 3

[0043] (1) According to the synthesis of 10g of Na 0.5 Ni 0.23 Fe 0.13 mn 0.63 o 2 The molar ratio of Mn, Ni and Fe in the element is weighed manganese nitrate, nickel nitrate and ferrous nitrate and dissolved in 200mL of deionized water, the excess of sodium nitrate added is 5 mol%, stirring constantly, after the step metal salt is dissolved, weigh 5g Tartaric acid was added to the solution, stirred and evaporated to dryness at 100°C to obtain a gel substance.

[0044] (2) Vacuum-dry the gel obtained in step (1) at 100°C, crush it, pre-calcine at 600°C for 6 hours in an air atmosphere, then sinter at 1000°C for 18 hours, and cool to room temperature to obtain the pure phase P2 Manganese-based sodium-ion battery cathode material NaNFM.

[0045] (3) Weigh 5g of the pure-phase product NaNFM and disperse it in 25mL of absolute ethanol and 25mL of acetone mixed solution, stir for 3 hours to obtain a uniformly dispersed suspension, and then 2 (PO 4 ) 3 The mass ratio to NaN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com