Preparation method of high-performance and voltage-reversal-resistant membrane electrode assembly

A membrane electrode assembly and anti-voltage technology, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve problems such as short circuit, affecting the durability of proton exchange membrane fuel cells, and explosion, so as to improve battery performance and prolong anti-voltage reversal time, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

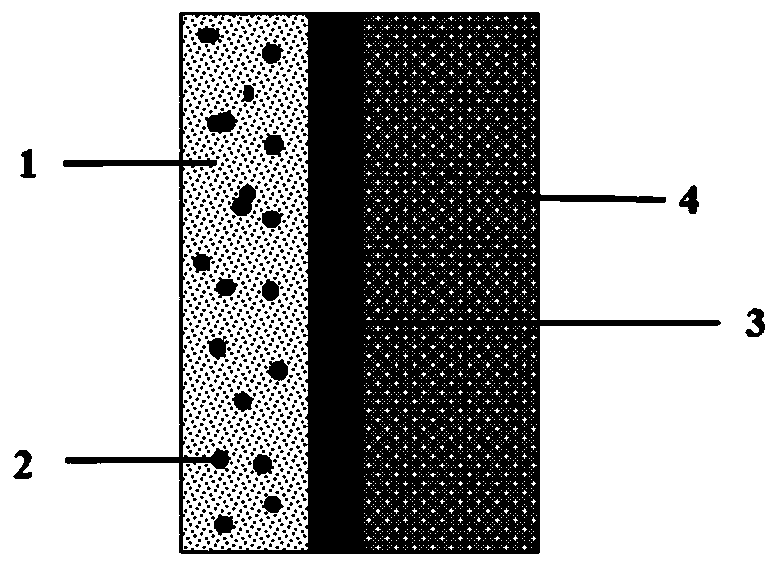

preparation example Construction

[0047] Described preparation method specifically comprises the following steps:

[0048] Step 1. Prepare anode slurry:

[0049] Add the catalyst into the beaker, then weigh the anti-reversed electrolytic water catalytic material and add it to the beaker, add an appropriate amount of nafion solution, stir for 10-15 minutes, then add a dispersant to the beaker, and obtain the required Uniformly dispersed anode slurry. Wherein, the mass ratio of the catalyst to the anti-counterelectrode electrolysis water catalytic material is 1: (0.1-10). The catalyst is a conventional platinum-carbon catalyst, or a graphitized platinum-carbon catalyst, or a transition metal composition comprising a transition metal and nitrogen is formed on a carbon carrier, wherein the transition metal is selected from copper, silver, vanadium, chromium, molybdenum, Tungsten, manganese, cobalt, nickel, cerium and combinations thereof; the mass ratio of carbon content to nafion in the catalyst is 1: (0.1-1). ...

Embodiment 1

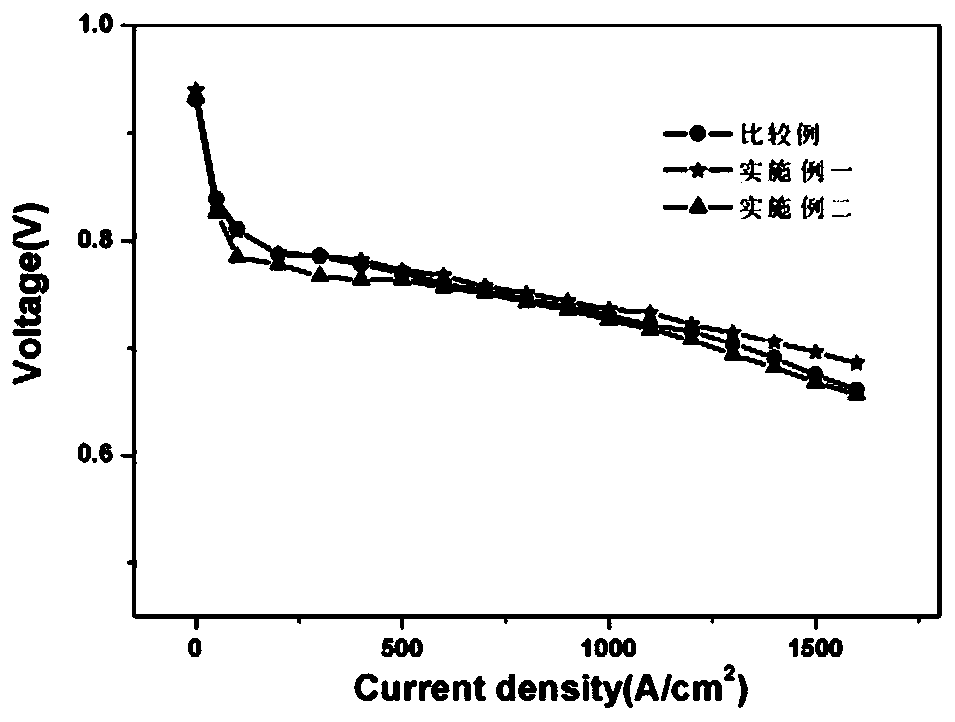

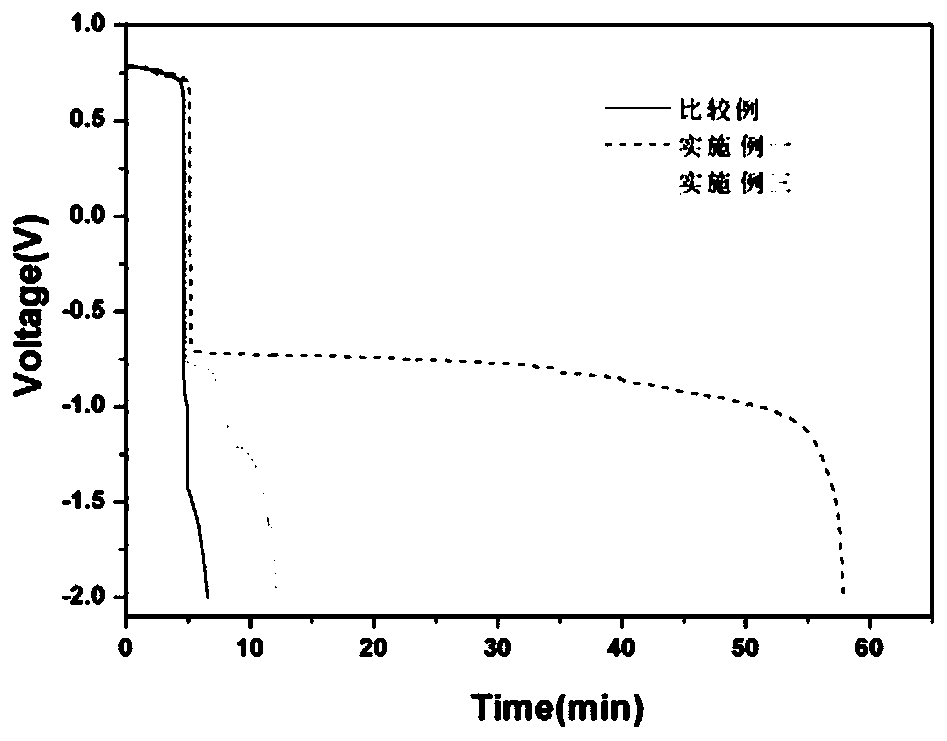

[0057] Such as Figure 1-3 Shown, carry out comparative experiment, be respectively three groups of embodiments and a group of comparative examples.

[0058] The specific operation process is as follows:

[0059] 1, the making of embodiment one MEA

[0060] Step 1. Preparation of anode slurry: Take 2g of catalyst and add it to a beaker, add anti-reverse electrolytic water catalytic material, add 20g of nafion solution, stir for 10 minutes, add 135g of dispersant, and obtain a uniformly dispersed anode slurry by ultrasonic dispersion , and spray the anode slurry on the anode side of the proton exchange membrane 3 .

[0061] In step 1, the catalyst is a graphitized platinum-carbon catalyst;

[0062] In step 1, the anti-reverse electrolytic water catalytic material is metal iridium and iridium oxide, and the mass ratio of platinum content in the graphitized platinum-carbon catalyst to the anti-reverse material is 1:0.5;

[0063] In step one, the mass ratio of carbon content a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com