Mask slurry and preparation method thereof

A paste and mask technology, used in metal material coating process, ion implantation plating, coating and other directions to achieve good printing performance, excellent thixotropic performance, and excellent anti-settling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

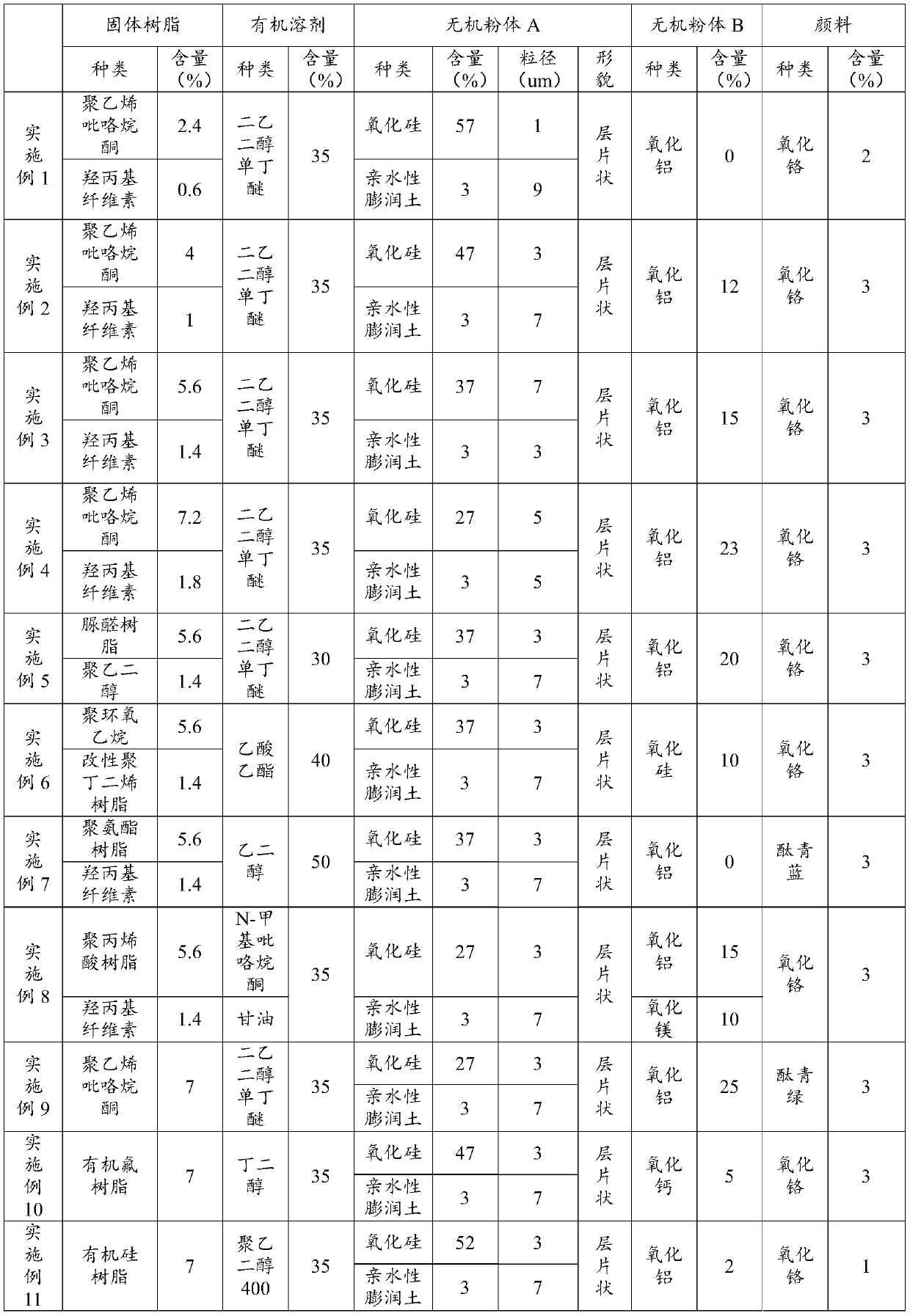

Embodiment 1

[0036] An embodiment of the masking slurry of the present invention, the components and amounts of the masking slurry described in this embodiment are shown in Table 1. At least one of the inorganic powders A is used after hydrophilic treatment. The hydrophilic treatment operation is: adsorb, coat or coat the surface of powder particles with water-soluble polymers such as polyethylene glycol, polyvinyl alcohol, and acrylic acid polymers, so that the powder is hydrophilic.

[0037] The preparation method of the mask slurry described in this embodiment is:

[0038] (1) Preparation of the organic vehicle: add the solid resin into the organic solvent and mix evenly, fully stir and dissolve completely, and filter through a 250-325 mesh screen to obtain the organic vehicle for use;

[0039] (2) Preparation of mask slurry: Add the organic carrier, inorganic powder A, inorganic powder B, and pigment obtained in step (1) into a mixing tank for mixing, and then roll through a three-rol...

Embodiment 2~28

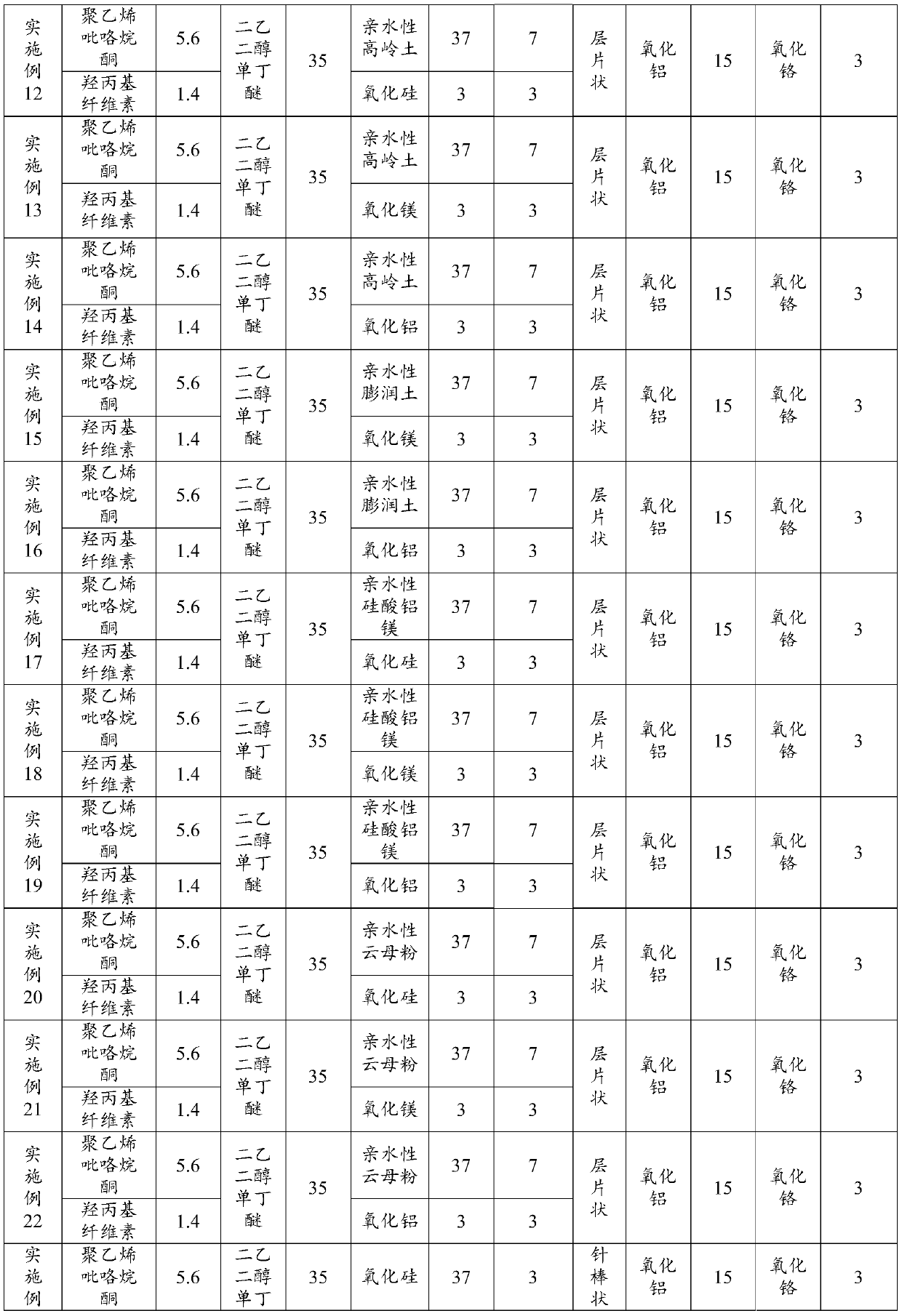

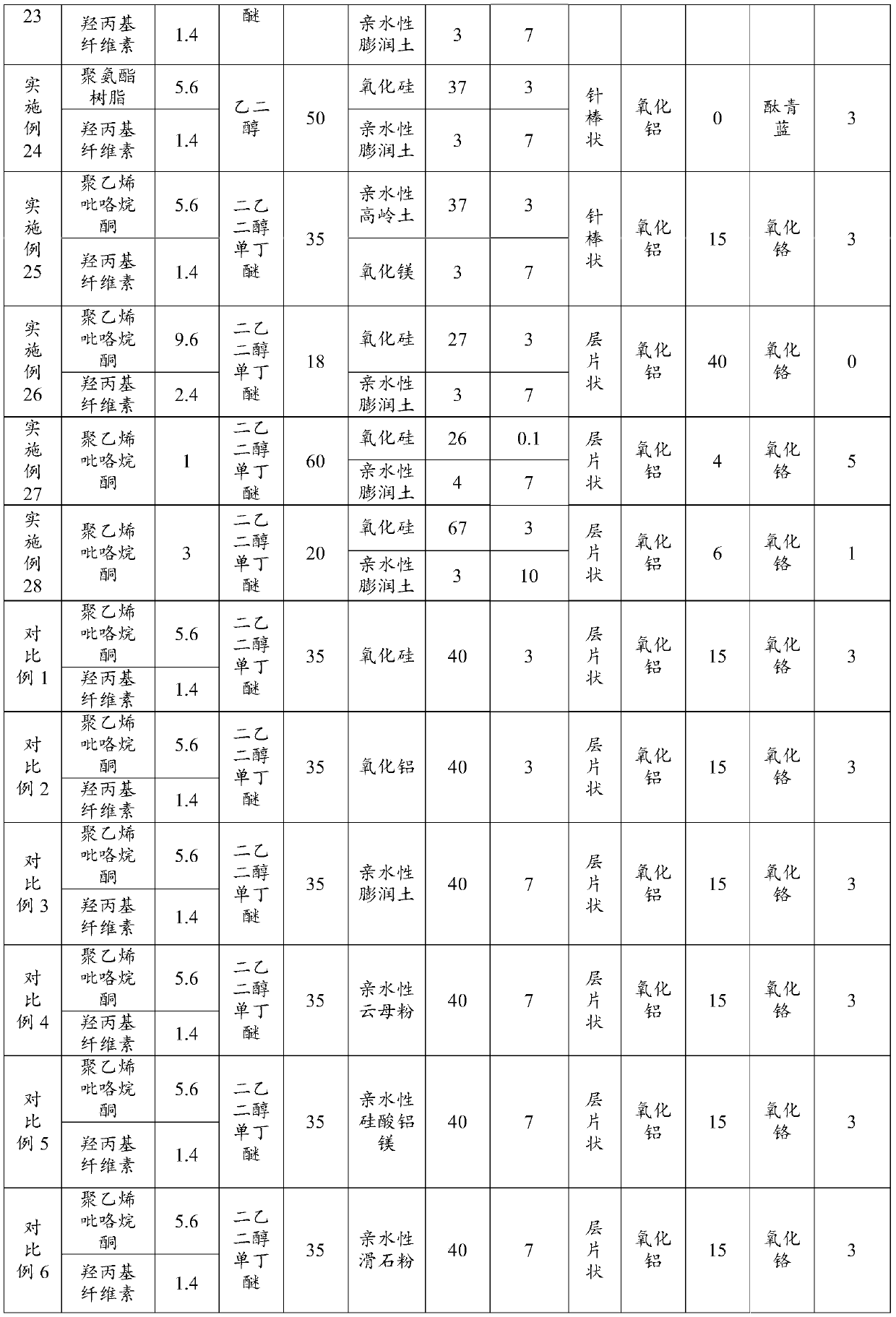

[0041] The components and dosages of the masking pastes described in Examples 2-28 are shown in Table 1. The preparation method of the masking pastes described in Examples 2-28 is the same as that of Example 1.

Embodiment 3

[0067] In Example 3 and Examples 12-22, the mass percentages of each component are the same, the specific substances of solid resin, organic solvent, inorganic powder B, and pigment are the same, and only the selected substances of inorganic powder A are different. It can be seen from Table 3 that the mask paste prepared in Example 3 has the best printing performance, washing ability and dry film adhesion; that is, when the inorganic powder A is silicon oxide and bentonite, the mask paste has the best Excellent printing performance, washing ability, dry film adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com