A fe for thermal spraying 3 o 4 -co 3 o 4 Powder Preparation Method

A fe3o4-co3o4, thermal spraying technology, applied in coating, fusion spraying, metal material coating process, etc., can solve the problem of low thermal radiation coefficient of coating of metal parts, achieve high thermal radiation coefficient, stable structure, The effect of increasing the thermal radiation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A Fe for thermal spraying 3 o 4 -Co 3 o 4 The preparation method of powder, comprises the following steps:

[0027] (1) Fe 3 o 4 Impurity removal: select Fe with a purity of more than 99% and a particle size of 1 μm 3 o 4 Commercially available mechanical crushing powder. Because it contains a certain amount of impurity elements, such as S, Si and so on. Fe 3 o 4 The powder is first heat-treated to remove Fe 3 o 4 The volatile impurities contained in the powder are further removed by chemical impregnation to obtain purified Fe 3 o 4 powder; the specific steps are: the original Fe 3 o 4 The powder is put into a heat treatment furnace, and under the protection of an inert atmosphere, the temperature is raised to 450 ° C, and the heat treatment time is 3 hours to remove the original Fe 3 o 4 The volatile impurities in the powder are removed, cooled naturally, and the first-grade Fe is obtained 3 o 4 Purified powder; then the primary Fe 3 o 4 The purifi...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, the difference is:

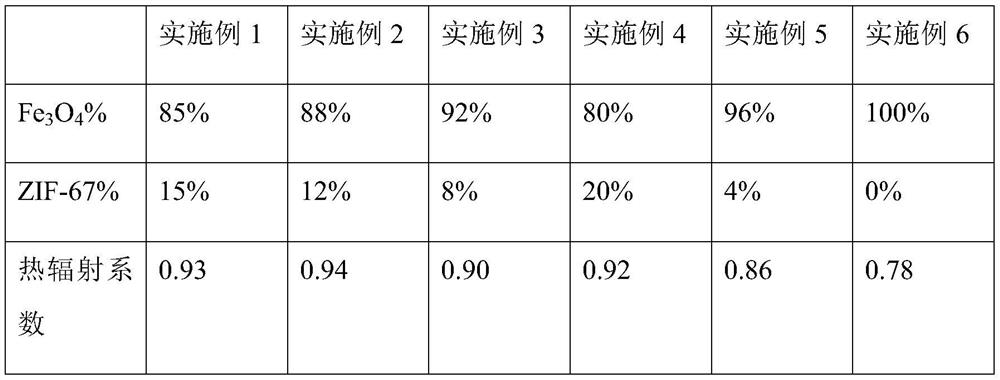

[0035] In the batching, the following powders are batched according to weight percentage, 88% of the purified Fe 3 o 4 Powder, 12% ZIF-67 powder.

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 1, the difference is:

[0038] In the batching, the following powders are batched according to weight percentage, 92% of the purified Fe 3 o 4 Powder, 8% ZIF-67 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com