Cross-linking type aqueous binder for lithium ion battery and electrode prepared from cross-linking type aqueous binder

A technology of lithium-ion batteries and binders, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of silicon-based negative electrode cycle irreversible capacity increase, shedding, etc., to achieve uniformity of dispersion, maintain stability, The effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

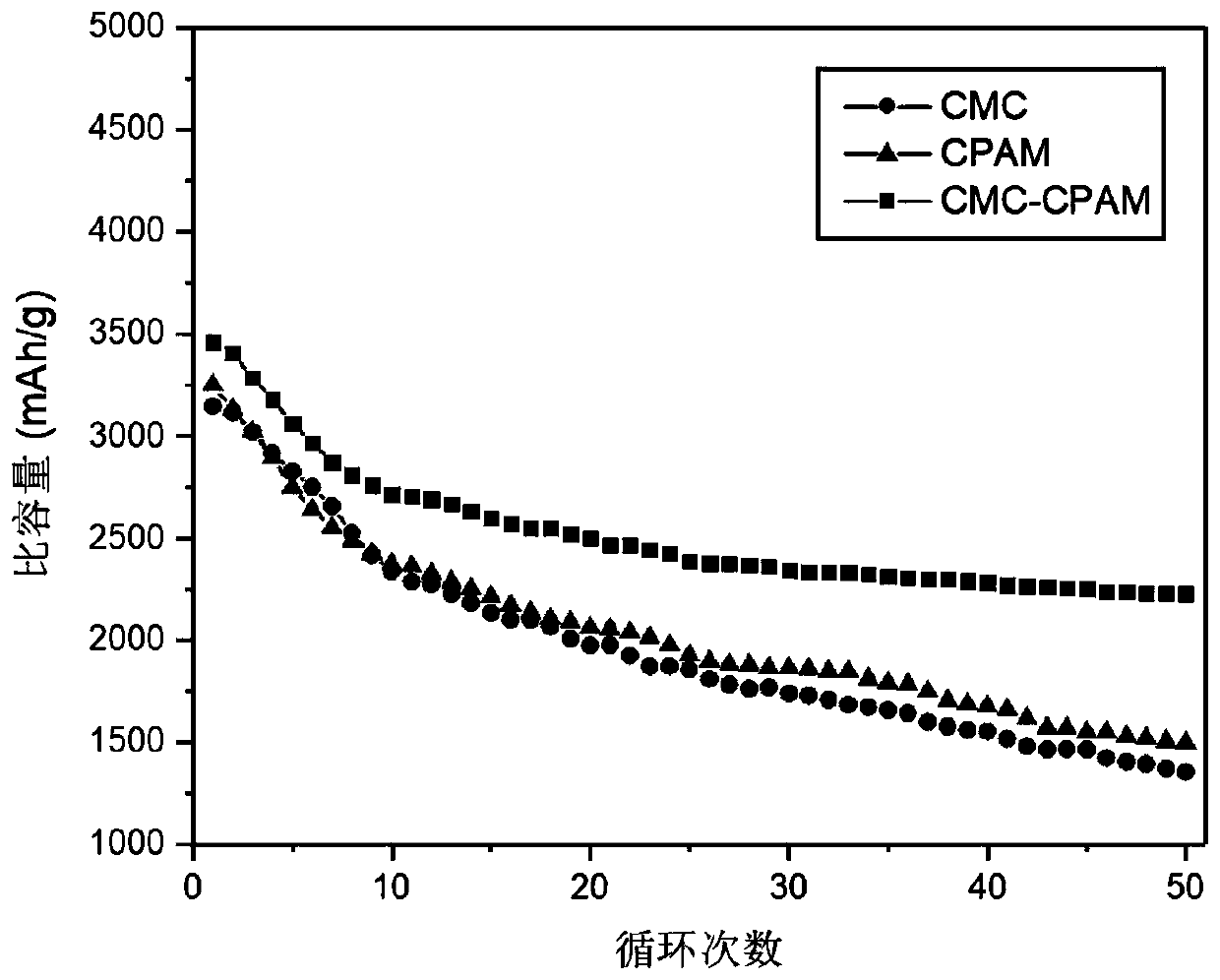

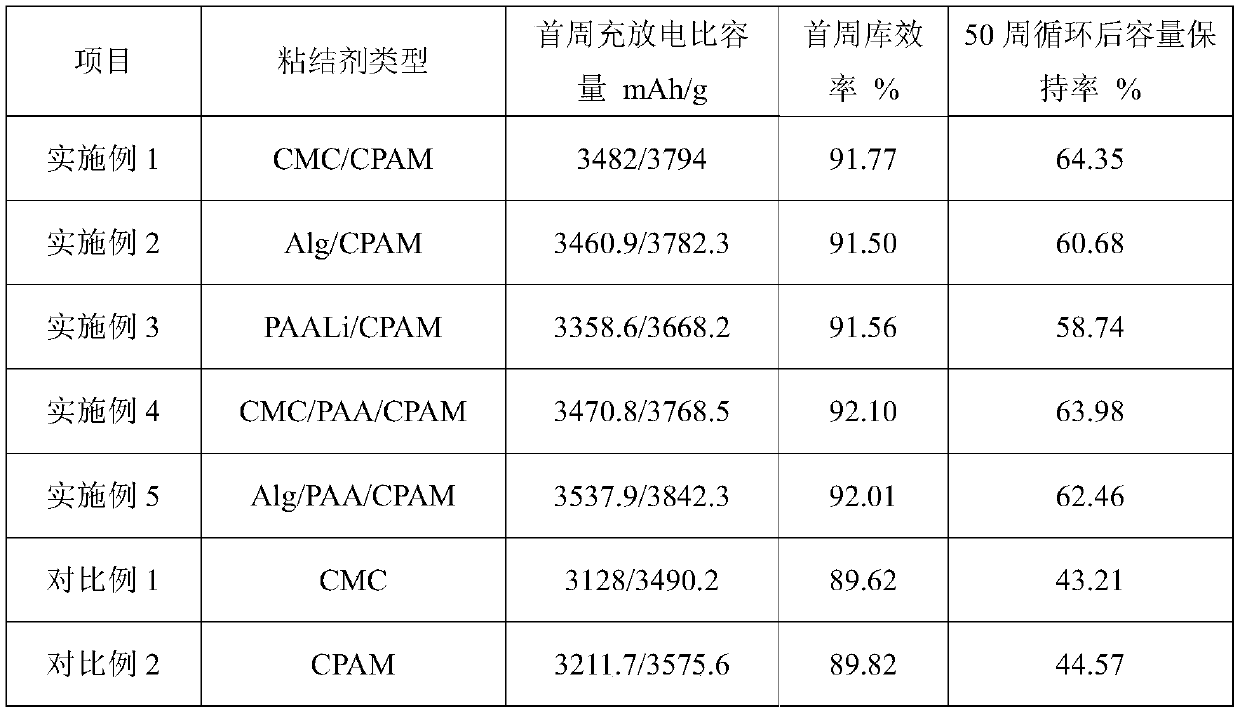

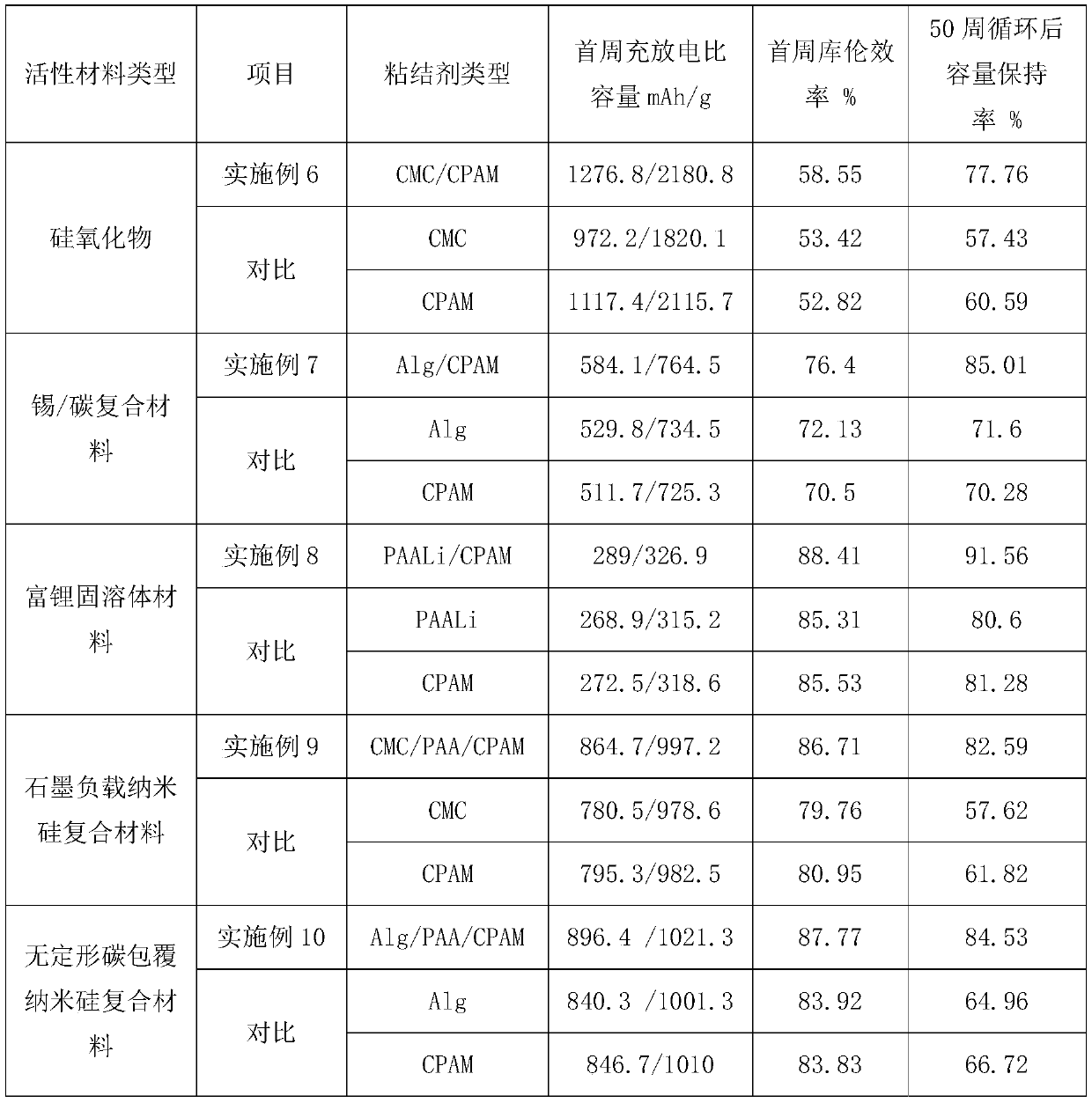

Embodiment 1

[0031] Electrode preparation: Sodium carboxymethylcellulose (CMC) and cationic polyacrylamide (CPAM) were prepared into 2% aqueous solutions respectively. Take 0.45g of spherical nano-silicon particles with a particle size distribution of 50-150nm and 0.15g of conductive carbon black (super-P) into 3.75g of sodium carboxymethyl cellulose aqueous solution and mix well, then add 3.75g of cationic The polyacrylamide aqueous solution is mixed evenly with the above slurry. The prepared slurry is evenly coated on the copper foil current collector, and the loading amount of the active material nano-silicon is controlled at 1 mg / cm 2 About; air-dry the pole piece obtained above at room temperature, then cut the pole piece into a disc with a diameter of 14mm, and compact it with a roller press, and the compaction density is controlled at 0.8g / cm 3 . Active material in the obtained electrode: conductive agent: binder = 60:20:20.

[0032]The electrode prepared above was vacuum-dried a...

Embodiment 2

[0035] Electrode preparation: Sodium alginate (Alg) and cationic polyacrylamide (CPAM) were prepared into 2% aqueous solutions respectively. Take 0.45g of lamellar nano-silicon particles with a diameter of 100-150nm and a thickness of 30nm, and 0.15g of conductive carbon black (super-P) into 5g of sodium alginate aqueous solution and mix well, then add 2.5g of cations The polyacrylamide aqueous solution is mixed evenly with the above slurry. The prepared slurry is evenly coated on the copper foil current collector, and the loading amount of the active material nano-silicon is controlled at 1 mg / cm 2 About; air-dry the pole piece obtained above at room temperature, then cut the pole piece into a disc with a diameter of 14mm, and compact it with a roller press, and the compaction density is controlled at 0.8g / cm 3 . Active material in the obtained electrode: conductive agent: binder = 60:20:20.

[0036] The electrode prepared above was vacuum-dried at 100° C. for 12 h to remo...

Embodiment 3

[0039] Electrode preparation: Lithium polyacrylate (PAALi) and cationic polyacrylamide (CPAM) were prepared into 2% aqueous solutions respectively. Take 0.45g of silicon nanowires with a length of 1-2μm and a diameter of 60-150nm and 0.15g of conductive carbon black (super-P) into 4.5g of an aqueous solution of lithium polyacrylate and mix well, then add 3g of cationic polyacrylate The acrylamide aqueous solution is uniformly mixed with the above slurry. The prepared slurry is evenly coated on the copper foil current collector, and the loading amount of the active material nano-silicon is controlled at 1 mg / cm 2 About; air-dry the pole piece obtained above at room temperature, then cut the pole piece into a disc with a diameter of 14mm, and compact it with a roller press, and the compaction density is controlled at 0.8g / cm 3 . Active material in the obtained electrode: conductive agent: binder = 60:20:20.

[0040] The electrode prepared above was vacuum-dried at 100° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com