Preparation method and application of platinum-based catalyst based on etching treatment carbon carrier

A carbon carrier and catalyst technology, which is applied in the field of preparation of platinum-based catalysts, can solve the problems of poor catalytic activity and stability, hinder the development and application of HT-PEMFC, and the catalyst is prone to aging, so as to achieve low cost and increase electrochemical efficiency. Active surface area, effects of limiting migration and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Etching treatment of carbon support

[0034] Weigh 500 mg of carbon powder (Vulcan XC-72) and add it to an acetone solution that is about twice the volume of carbon powder, stir at room temperature for 3 hours, filter and wash with deionized water, and then vacuum dry at 80 °C; obtain acetone-treated carbon Support; acetone-treated carbon support was added to 10 wt% HNO 3 and 30wt%H 2 O 2 In the mixture (volume ratio HNO 3 :H 2 O 2 =2:1), refluxed at 60°C for 5h, filtered, washed with deionized water until neutral, and dried in vacuum at 80°C; 100mg of the dried carbon powder was added to 100ml of Fe with a concentration of 0.5mol / L (NO 3 ) 3 The solution was stirred at room temperature for 1 h, dried in a drying oven, and then sintered in a muffle furnace at 370 °C for 6 h; the samples after high temperature sintering were washed with dilute hydrochloric acid solution and deionized water, and dried to obtain the etched the carbon carrier;

[0035] (2) Prep...

Embodiment 2

[0040] The carbon powder (Vulcan XC-72) in Example 1 was replaced with carbon fibers, and the remaining steps were the same as those in Example 1, and finally a Pt-based catalyst using an etched carbon support was obtained.

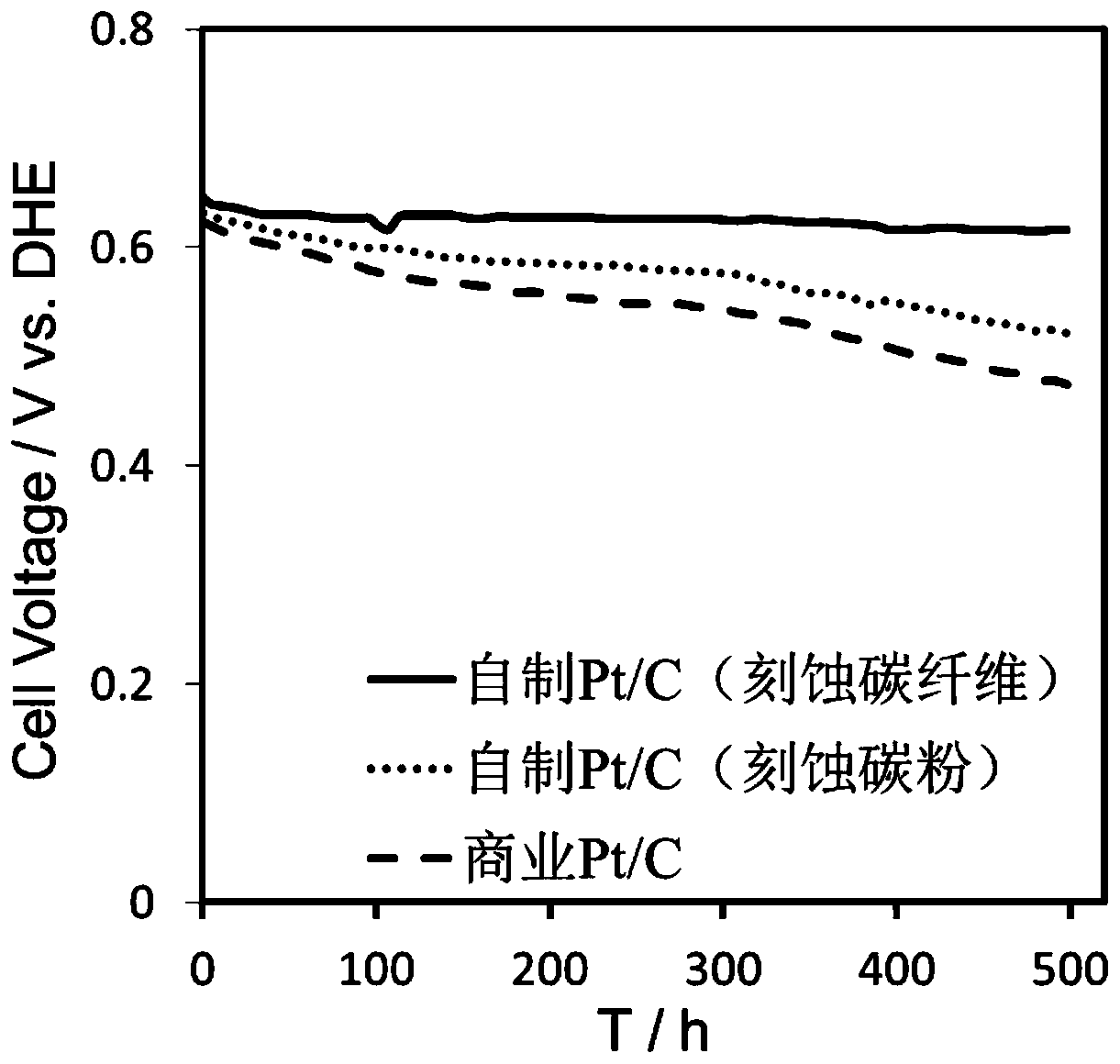

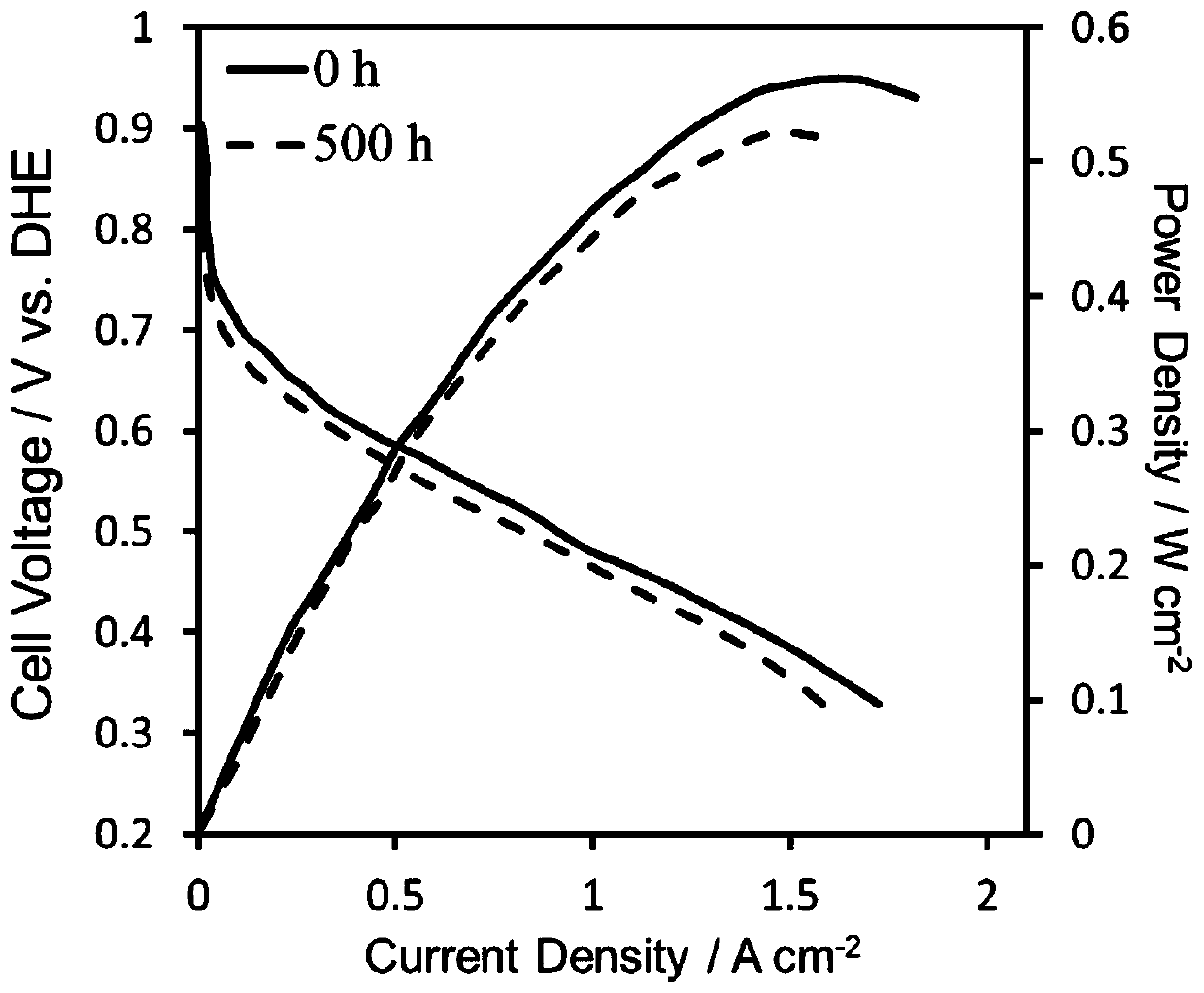

[0041] from figure 1 It can be seen that the voltage decay rate of the single cell is 57 μV / min. from image 3 It can be seen from the polarization curve of -2 down to 0.56W cm -2 , about 5.08%; 0.5A cm -2 The voltage at the discharge current density decreased from 0.59V to 0.56V, about 5.08%.

Embodiment 3

[0043] (1) Preparation of carbon carrier:

[0044] Weigh 500 mg of carbon powder (Vulcan XC-72) and add it to an acetone solution with twice the volume of carbon powder, stir at room temperature for 3 h, filter and wash with deionized water, and then vacuum dry at 80 °C; 10wt% HNO 3 and 30wt%H 2 O 2 In the mixture (volume ratio HNO 3 :H 2 O 2 =1:1), refluxed at 50 °C for 8 h, filtered, washed with deionized water until neutral, and dried in vacuum at 80 °C; 100 mg of the dried carbon powder was added to 100 ml of 0.5mol / L Fe(NO) 3 ) 3 In the solution, stir at room temperature for 1 h, put it into a drying box to dry, and then sinter it in a muffle furnace at 350 °C for 8 h; wash the sample after high temperature sintering with dilute hydrochloric acid solution and deionized water, and dry it to obtain a high specific gravity surface area carbon support;

[0045] (2) Preparation of catalyst:

[0046] Take 30mL of ethylene glycol (EG), add 2.65ml of 20mg / ml H dropwise u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com