A kind of amlodipine besylate tablet and preparation method thereof

A technology of amlodipine besylate tablets and amlodipine besylate, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve the problem of amlodipine besylate Unstable quality of tablet products, high content of related substances, etc., to improve stability and use safety, improve uniformity, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

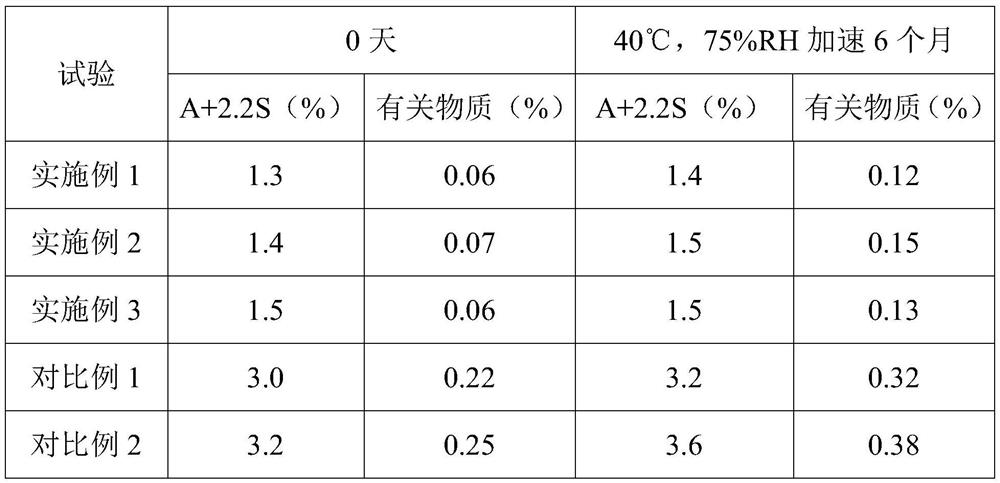

Examples

Embodiment 1

[0029] The present embodiment provides a kind of amlodipine besylate tablet, and its raw material is made up of following composition:

[0030] Amlodipine besylate 1.74kg; Microcrystalline cellulose PH101 29.52kg; Anhydrous calcium hydrogen phosphate 15kg; Add carboxymethyl starch sodium 0.75kg; Add carboxymethyl starch sodium 1.25kg; Mixed magnesium stearate 0.25kg; total mixed magnesium stearate 0.25kg.

[0031] The method for preparing amlodipine besylate sheet by adopting above-mentioned raw material composition comprises the steps:

[0032] (1) each component is taken by weighing according to above-mentioned formula, and amlodipine besylate is passed through a 100 mesh sieve, and the bulk drug under the sieve is taken for subsequent use;

[0033] (2) Microcrystalline cellulose PH101, anhydrous calcium hydrogen phosphate and sodium carboxymethyl starch added in the formula amount are placed in a wet granulator, mixed uniformly, then 18.1kg of purified water is added there...

Embodiment 2

[0038] This embodiment provides a kind of amlodipine besylate tablet, its raw material is composed of the same as embodiment 1 by the following composition.

[0039] The method for preparing amlodipine besylate sheet by adopting above-mentioned raw material composition comprises the steps:

[0040] (1) each component is taken by weighing according to above-mentioned formula, and amlodipine besylate is passed through a 100 mesh sieve, and the bulk drug under the sieve is taken for subsequent use;

[0041] (2) Place microcrystalline cellulose PH101, anhydrous calcium hydrogen phosphate and sodium carboxymethyl starch in a formula amount in a wet granulator, mix well, then add 19kg of purified water to it to make a soft material, and pass 30 Shake granulation with a mesh nylon sieve, dry the obtained granules in an oven at 55°C for 5 hours to make the moisture content <3.0%, and pass through a 20-mesh sieve for granulation to obtain the first granules;

[0042] (3) Amlodipine be...

Embodiment 3

[0046] This embodiment provides a kind of amlodipine besylate tablet, its raw material is composed of the same as embodiment 1 by the following composition.

[0047] The method for preparing amlodipine besylate sheet by adopting above-mentioned raw material composition comprises the steps:

[0048] (1) each component is taken by weighing according to above-mentioned formula, and amlodipine besylate is passed through a 100 mesh sieve, and the bulk drug under the sieve is taken for subsequent use;

[0049] (2) Place microcrystalline cellulose PH101, anhydrous calcium hydrogen phosphate and sodium starch glycolate in the wet granulator in the formula quantity, mix well, then add 18kg of purified water to it, make soft material, pass 30 Shake granulation with a mesh nylon sieve, dry the obtained granules in an oven at 65°C for 4 hours to make the moisture content <3.0%, and pass through a 20-mesh sieve for granulation to obtain the first granules;

[0050] (3) Amlodipine besylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com