Magnetic iron oxide-graphene nano composite material for removing dye pollution of water body as well as preparation method and application of magnetic iron oxide-graphene nano composite material

A technology of nanocomposite materials and magnetic iron oxide, which is applied in the direction of magnetic materials, diamagnetic/paramagnetic materials, water pollutants, etc., can solve the problems of limited popularization, non-recyclable use, and high cost of use, and achieves environmental friendliness and has Effect of recycling and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

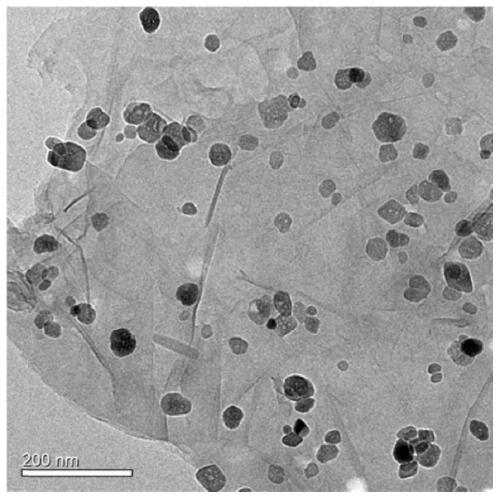

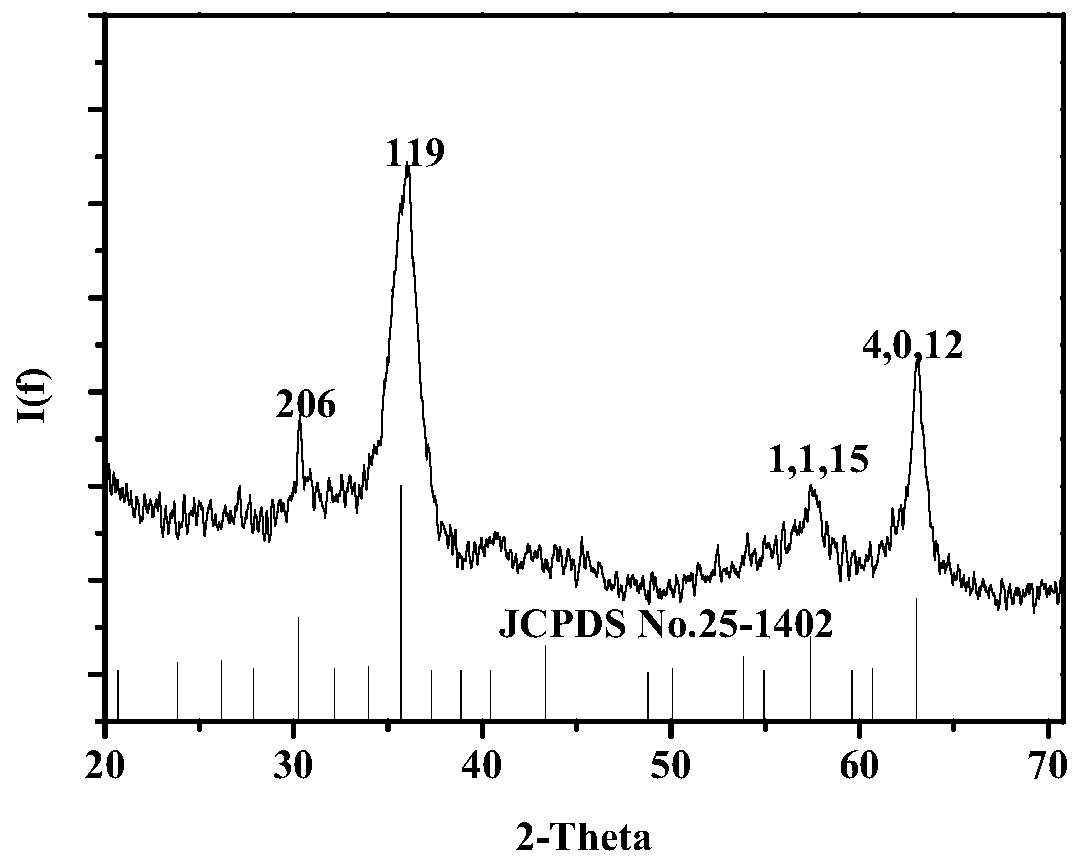

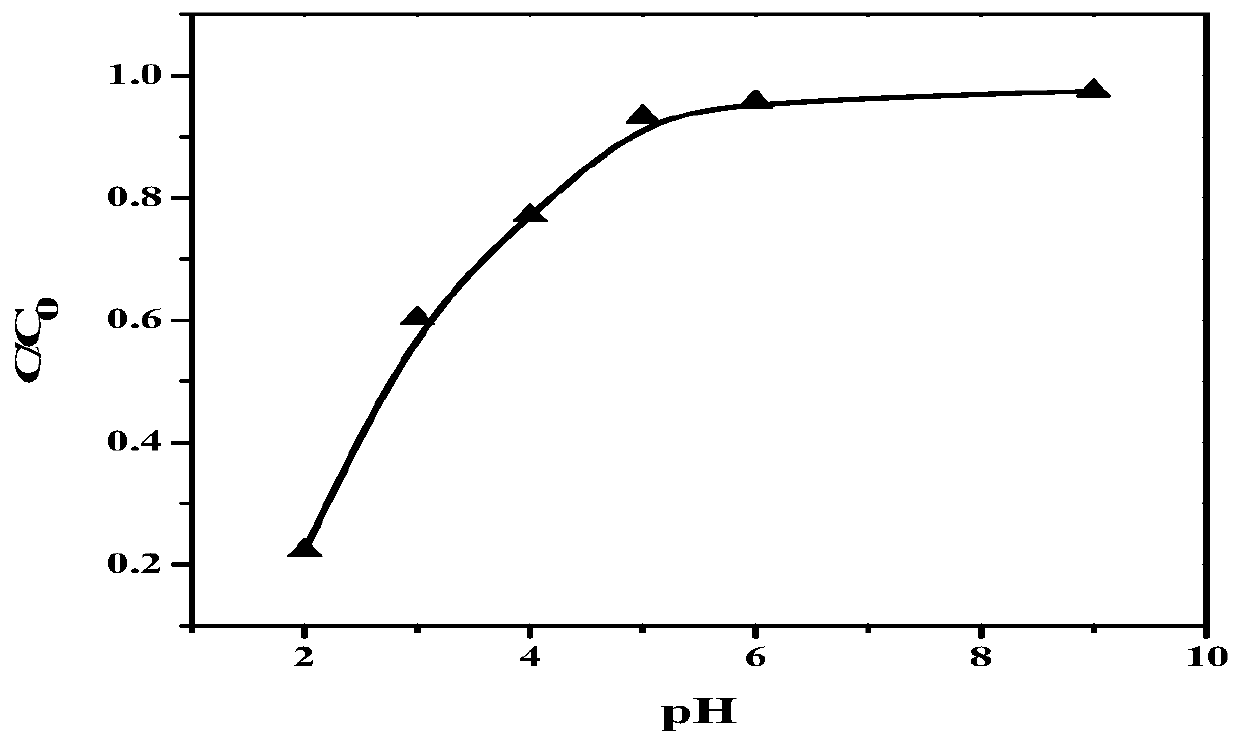

Image

Examples

Embodiment 1

[0033] (1) Dissolve 0.0375g of graphene oxide (GO) in 15ml of deionized water for ultrasonication to fully disperse GO in deionized water.

[0034] (2) According to the mass ratio of graphene oxide and ferric chloride, it is 1:30~40 to take ferric chloride (take by weighing 1.352g ferric chloride in this embodiment), according to the quality of ferric chloride and sodium citrate The ratio is 7-8:1 Weigh sodium citrate (weigh 0.1837g sodium citrate in this example), mix 1.352g ferric chloride and 0.1837g sodium citrate, and prepare 5ml mixed solution.

[0035] (3) Slowly drop the GO mixed solution into the mixed solution under ultrasonic conditions.

[0036] (4) After ultrasonication for 30 minutes, adjust the pH of the final solution to about 10 with 5 mol NaOH solution (the pH can be between 9 and 11, and the preferred pH in this embodiment is around 10), and then continue ultrasonication for 30 minutes.

[0037] (5) Transfer the final solution to a polytetrafluoroethylene-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com