COF material-loaded transition metal catalyst, and preparation method and application thereof

A transition metal and catalyst technology, which is applied to COF material-supported transition metal catalysts and their preparation and application fields, can solve the problems of inability to control the degree of hydrogenation reaction, complex catalyst preparation process, and small application range of substrate alkynes, etc. It has the advantages of wide application range, easy recycling and reuse, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

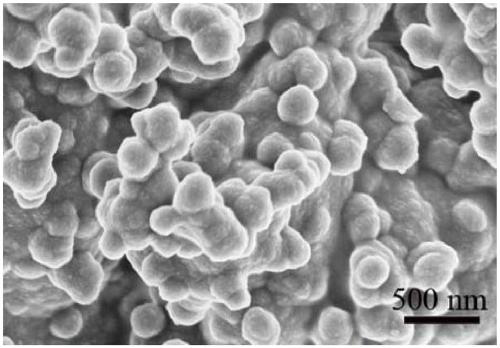

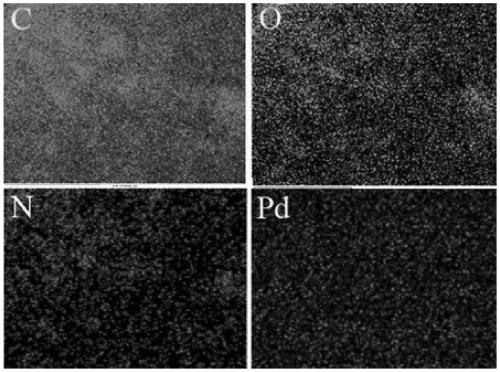

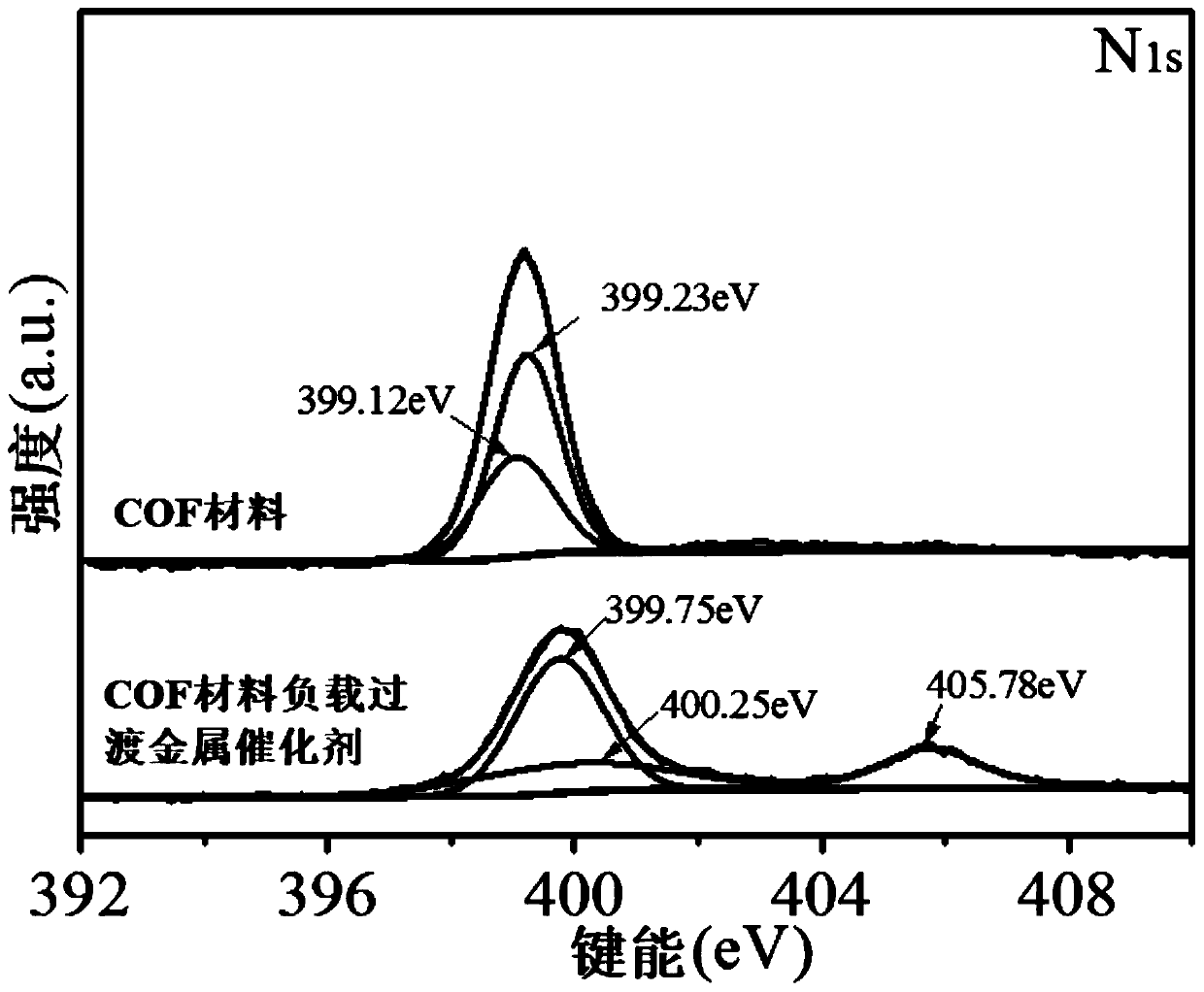

[0034] A kind of COF material supports transition metal catalyst, and its preparation method comprises the following steps:

[0035] 1) Mix 2.38mmol of 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde, 3.57mmol of tris(4-aminophenyl)amine and 60mL of absolute ethanol, stir at room temperature for 30min, and The product was subjected to centrifugation and suction filtration, and then the solid obtained by suction filtration was added to N,N-dimethylformamide, stirred and refluxed at 160°C for 5 hours, then centrifuged and suction filtered, and then the solid obtained by suction filtration was added to absolute ethanol Stir and reflux at 80°C for 3 hours, then perform centrifugation and suction filtration, and finally vacuum-dry the solid obtained by suction filtration at 80°C for 24 hours to obtain a COF material. The synthesis route is as follows:

[0036]

[0037] 2) Mix 160mg of COF material, 20mg of palladium acetate and 10mL of dichloromethane, stir at 25°C for 24h for imp...

Embodiment 2

[0040] A kind of COF material supports transition metal catalyst, and its preparation method comprises the following steps:

[0041] 1) Mix 2.38mmol of 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde, 3.57mmol of 4,4-diaminodiphenylsulfide and 60mL of absolute ethanol, stir at room temperature for 30min, Centrifuge and suction filter the product, then add the solid obtained by suction filtration into N,N-dimethylformamide, stir and reflux at 160°C for 5 hours, then perform centrifugation and suction filtration, and then add the solid obtained by suction filtration into absolute ethanol Stir and reflux at 80°C for 3 hours, then perform centrifugation and suction filtration, and finally vacuum-dry the solid obtained by suction filtration at 80°C for 24 hours to obtain a COF material. The synthesis route is as follows:

[0042]

[0043] 2) Mix 160mg of COF material, 15mg of nickel acetate and 10mL of dichloromethane, stir at 25°C for 24h to impregnate and load, centrifuge and fi...

Embodiment 3

[0045] A kind of COF material supports transition metal catalyst, and its preparation method comprises the following steps:

[0046] 1) Mix 2.38mmol of terephthalaldehyde, 3.57mmol of melamine and 60mL of absolute ethanol, stir at room temperature for 30min, centrifuge and suction filter the product, and then add the solid obtained by suction filtration into N,N-dimethyl Stir and reflux in formamide at 160°C for 5 hours, then perform centrifugation and suction filtration, then add the solid obtained by suction filtration into absolute ethanol at 80°C and stir for reflux for 3 hours, then perform centrifugation and suction filtration, and finally place the solid obtained by suction filtration in Vacuum drying at 80°C for 24 hours to obtain the COF material, the synthesis route is as follows:

[0047]

[0048] 2) Mix 160mg of COF material, 15mg of palladium acetate and 10mL of dichloromethane, stir at 25°C for 24h for impregnation and loading, centrifuge and suction filter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com