Autotrophic nitrogen removal integrated system based on MBBR and quick starting method

An autotrophic denitrification, main technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. , to achieve the effect of saving land, simple operation and land saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

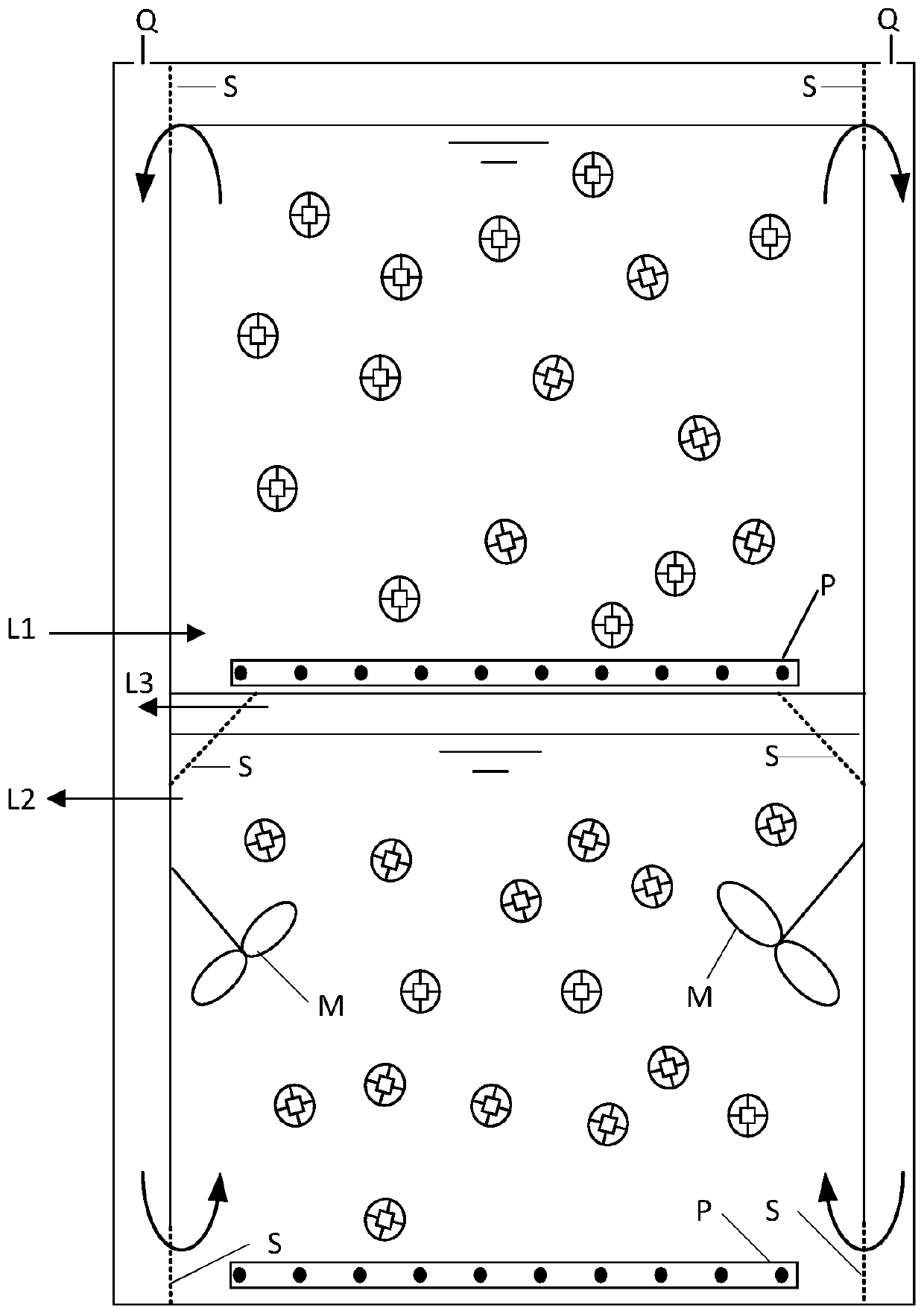

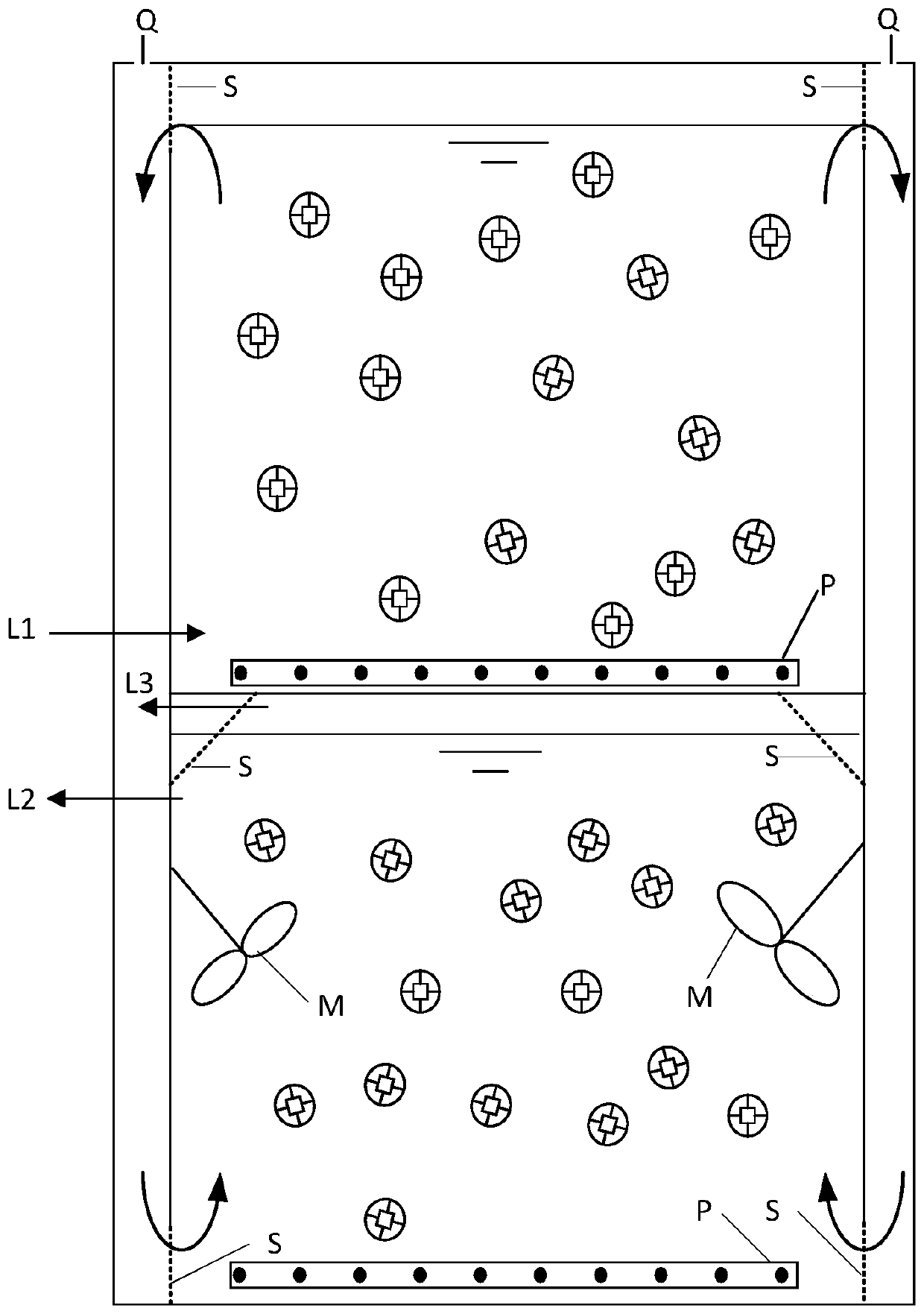

Embodiment 1

[0058] For an integrated device, the influent ammonia nitrogen and COD are 400mg / L and 320mg / L respectively, and the water volume is 300m 3 / d, using MBBR-based autotrophic denitrification integrated system, the total volume of the device is 60m 3 , in the first and second reaction tanks, the suspension carrier is added, and the filling rate is 45%. The first reaction tank is inoculated with ordinary activated sludge. From bottom to top, aeration is used to ensure the fluidization of sludge and suspended carriers in the first reaction tank on the upper part of the device and the second reaction tank on the lower part of the device, and the sludge in the first and second reaction tanks is gradually lost by the rapid sludge discharge method until the second reaction tank The sludge concentration in the first and second reaction tanks is 0.30g / L; the DO in the first reaction tank is controlled at 2-3mg / L, and the aeration intensity is controlled at 4.0m 3 / (m 2 h), run until th...

Embodiment 2

[0060] In an integrated device, suspension carriers are added to both the first and second reaction tanks, with a filling rate of 50%; ordinary activated sludge is inoculated in the first reaction tank, and the sludge concentration in the first and second reaction tanks after inoculation is 3.0g / L, the water flows from bottom to top, through aeration, the sludge and suspended carrier in the first reaction tank at the upper part of the device and the second reaction tank at the lower part of the device are fluidized, and the sludge in the first and second reaction tanks is made Gradually lose until the sludge concentration in the first and second reaction tanks is 0.37g / L; control the DO in the first reaction tank at 2-3mg / L, and the aeration intensity is 4.8m 3 / (m 2 h), run until the ammonia oxidation volume load in the first reaction tank is 1.37kgN / (m 3 d), inoculate the mature anammox suspension carrier into the second reaction tank, the inoculation rate is 4.1%, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com