A kind of oled material and its application in organic electroluminescence device

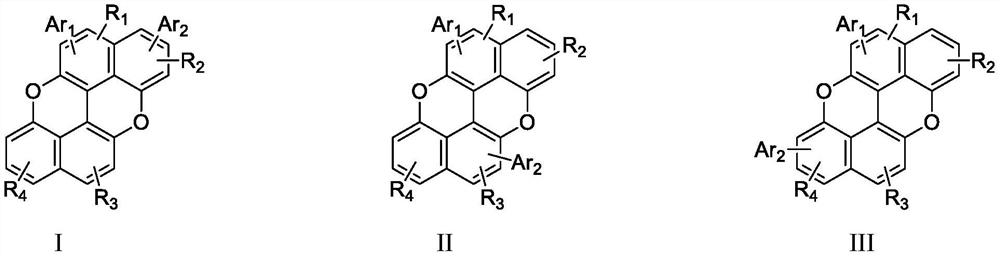

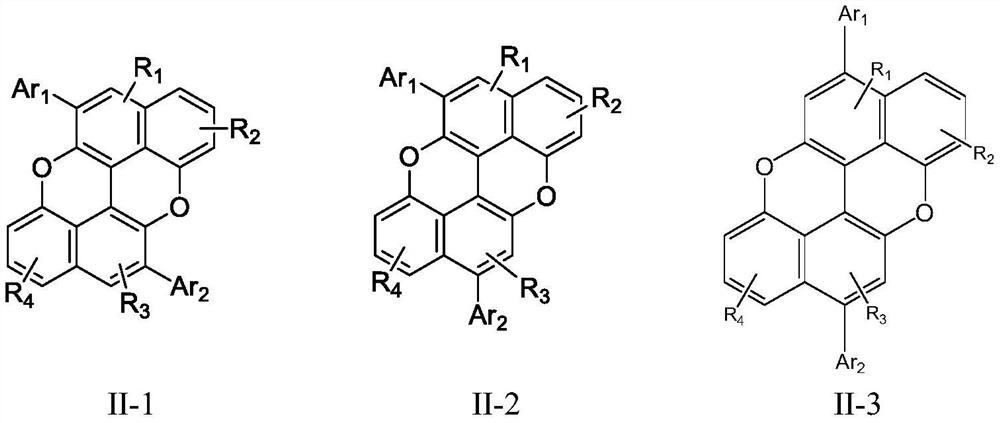

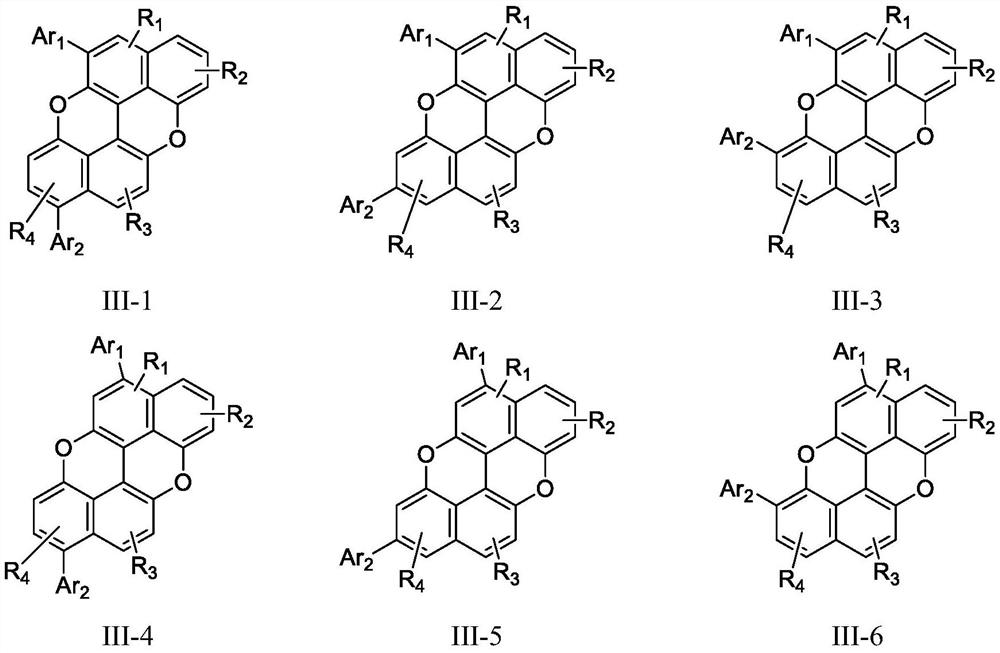

An electroluminescent device, organic technology, applied in the fields of electro-solid devices, organic chemistry, luminescent materials, etc., can solve the problems of affecting the service life of materials, destruction of film uniformity, low glass transition temperature, etc., and achieve high glass transition temperature. , not easy to crystallize, high thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065](Compound II-1-4) synthesis

[0066]The synthetic route is as follows:

[0067]

[0068]Synthesis of Compound II-1-4

[0069]1 liters of three flasks, mixing magnetic stirring, nitrogen gas replacement sequentially (0.378 mol) (4- (9H-carbazole-9-yl) phenyl) boric acid 60.27 g (purity 99%, 0.21 mol) And 100 ml of toluene. 0.5 g of PD132 was sequentially added after the nitrogen replacement. After completion, heating heated to 80 ° C. It was initially added to a solution of 44 g of compound P1 (purity 99%, 0.1 mol) and 100 ml of toluene, and the temperature was controlled from 75-90 ° C. Cooling to room temperature, add 100 ml of deionized hydrolysis, stirring for 10 minutes, filtration, and the filter cake was purged with DMF a few times, and 60.36 g of pale yellow solid was filtered, purity 99%, yield 79%.

[0070]Product MS (M / E): 523; Element Analysis (C38Hide21NO2: Theoretical value C: 87.17%, H: 4.04%, N: 2.68%, o: 6.11%; measured value C: 87.16%, H: 4.05%, N: 2.68%, o: 6.11%.

Embodiment 2

[0072](Compound II-1-14) synthesis

[0073]The synthetic route is as follows:

[0074]

[0075]Synthesis of Compound II-1-14

[0076]1 liters of three flasks, mixing magnetic stirring, nitrogen gas replacement sequentially add 40.07 g (0.378 mol), (5-phenyl-5H-benzo [b] carbazole-3-yl) boric acid 70.77 g (purity 99%) , 0.21 mol) and 100 ml of toluene. 0.5 g of PD132 was sequentially added after the nitrogen replacement. After completion, heating heated to 80 ° C. It was initially added to a solution of 44 g of compound P1 (purity 99%, 0.1 mol) and 100 ml of toluene, and the temperature was controlled from 75-90 ° C. Cooling to room temperature, add 100 mL of deionized water hydrolysis, stirring for 10 minutes, filtered, and the filter cake was repeatedly cooked several times, filtered to give 46.41 g of light yellow solid, purity 99%, yield 81%.

[0077]Product MS (M / E): 573; Element Analysis (C42Hide23NO2: Theoretical value C: 87.94%, H: 4.04%, N: 2.44%, o: 5.58%; measured value C: 87.93%, H: 4...

Embodiment 3

[0079](Compound II-1-19) synthesis

[0080]The synthetic route is as follows:

[0081]

[0082]Synthesis of Compound II-1-19

[0083]1 liter three-mouth bottle, mixing magnetic stirring, 40.07 g (0.378 mol) of sodium carbonate, (9-phenyl-9H-dibenzene [A, C] carbazole-11-yl) boric acid 81.27 g The purity was 99%, 0.21 mol) and 100 ml of toluene. 0.5 g of PD132 was sequentially added after the nitrogen replacement. After completion, heating heated to 80 ° C. It was initially added to a solution of 44 g of compound P1 (purity 99%, 0.1 mol) and 100 ml of toluene, and the temperature was controlled from 75-90 ° C. Cooling to room temperature, add 100 mL of deionized hydrolysis, stirring for 10 minutes, filtration, and filter cake with DMF. Cooked several times, filtered to give 49.84 g of pale yellow solid, purity 99%, yield 80%.

[0084]Product MS (M / E): 623; Element Analysis (C46Hide25NO2: Theory value C: 88.58%; H: 4.04%; N: 2.25%; o: 5.13%; measured value C: 88.57%; H: 4.05%; N: 2.25%; o: 5.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com