Electrodeposition method for preparing nickel oxide nanosheet supported nickel-molybdenum oxide quantum dots

A nickel oxide nanosheet and electrodeposition technology, applied in the field of new material technology and chemical synthesis, to achieve excellent bifunctional hydrogen evolution and oxygen evolution activity and stability, strong binding force, and overcoming the effects of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

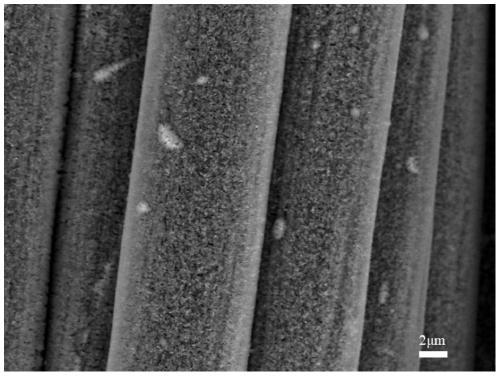

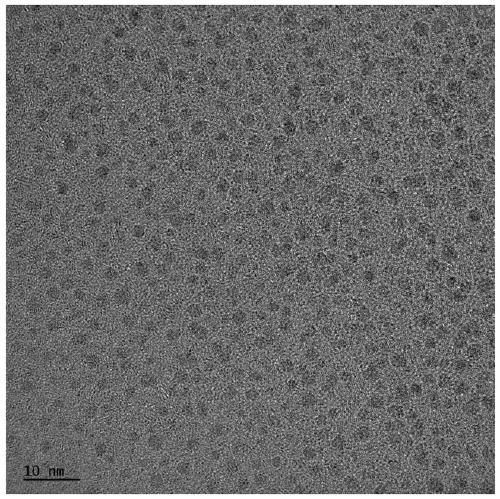

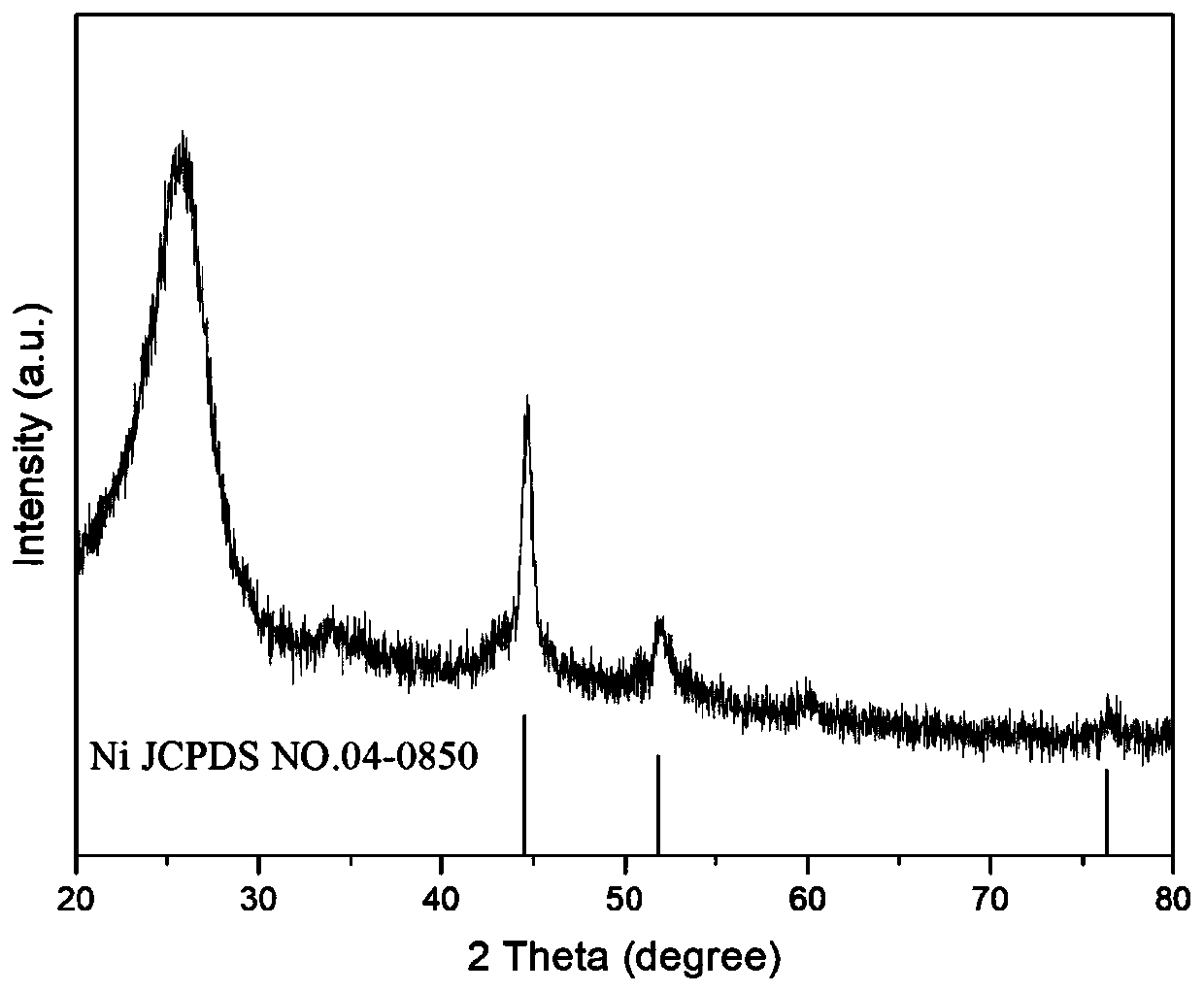

[0042]Weigh nickel acetate and ammonium molybdate and dissolve in deionized water respectively to obtain 5.078g / L nickel acetate electrolyte solution and 1.248g / L ammonium molybdate electrolyte solution; activate the surface of commercially available carbon cloth, and place the carbon cloth in succession Ultrasonic cleaning in acetone, alcohol, and deionized water for 10 minutes, taking out the carbon cloth and placing it in an acid solution (68wt% concentrated nitric acid and water are prepared according to the volume ratio of 1:3), and pouring it into the reaction of the polytetrafluoroethylene lining place it in an oven, activate it, keep it warm at 90°C for 12 hours, take it out and place it in deionized water for ultrasonic cleaning for 5 minutes, and then dry it in the oven for later use; use the surface-activated carbon cloth as the working electrode, and the carbon rod As a counter electrode, place it in the prepared nickel acetate electrolyte solution, use a workstatio...

Embodiment 2

[0055] Weigh nickel nitrate and ammonium molybdate and dissolve them in deionized water to obtain 1g / L nickel acetate electrolyte solution and 5g / L ammonium molybdate electrolyte solution; activate the surface of the carbon cloth, place the carbon cloth in acetone, alcohol, Ultrasonic cleaning in deionized water for 10 minutes, taking out the carbon cloth and placing it in an acid solution, pouring it into a polytetrafluoroethylene-lined reaction kettle, placing it in an oven, activating it, and keeping it warm at 60°C for 24 hours, After taking it out, put it in deionized water and ultrasonically clean it for 5 minutes, and then dry it in an oven for later use; use the surface-activated carbon cloth as the working electrode, and the carbon rod as the counter electrode, place it in the prepared nickel nitrate electrolyte solution, and use a workstation with a constant voltage of -1V Deposit for 14400s under high pressure to obtain the precursor material; place the deposited pre...

Embodiment 3

[0058] Weigh nickel sulfate and ammonium molybdate and dissolve in deionized water to obtain 20g / L nickel sulfate electrolyte solution and 0.1g / L ammonium molybdate electrolyte solution; activate the surface of carbon cloth, place carbon cloth in acetone, alcohol 1. Ultrasonic cleaning in deionized water for 10 minutes, take out the carbon cloth and place it in an acid solution, pour it into a polytetrafluoroethylene-lined reaction kettle, place it in an oven, activate it, and keep it warm at 120°C for 5 hours After taking it out, put it in deionized water and ultrasonically clean it for 5 minutes, and then dry it in the oven for later use; use the surface-activated carbon cloth as the working electrode, and the carbon rod as the counter electrode, place it in the prepared nickel sulfate electrolyte solution, and use the workstation -6V constant Press and deposit for 600s to obtain the precursor material; place the deposited precursor material in the prepared ammonium molybdate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com