Preparation process used for polyaniline aramid composite conductive fibers and applied to protective clothing

A polyaniline aramid fiber, composite conductive technology, applied in the direction of fiber processing, fiber type, ultrasonic/sonic fiber processing, etc., can solve the problems of uneven dispersion, weak binding force, and easy separation of polyaniline and aramid fiber. The effect of strong internal bonding, improved durability, and good lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

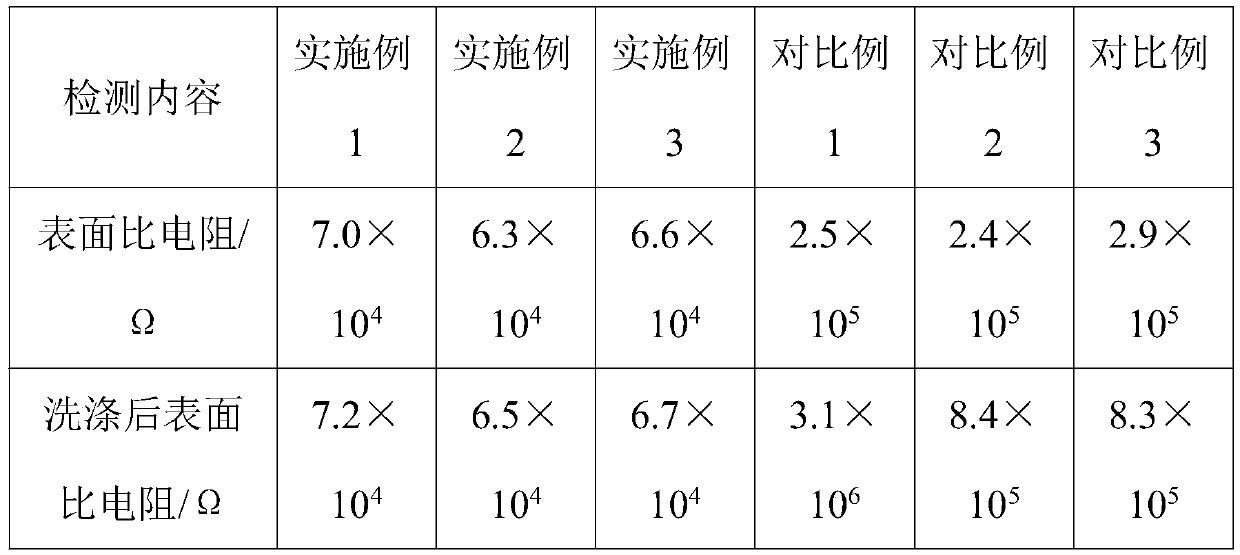

Examples

Embodiment 1

[0041]Move the aramid fibers into a plasma reactor, and in an oxygen atmosphere, control the oxygen pressure to 40Pa, and the oxygen flow rate to 8mL / min, and conduct plasma treatment for 20 minutes to obtain plasma-treated aramid fibers;

[0042] Add the plasma-treated aramid fiber into the sodium periodate solution with a mass fraction of 3%, stir and mix for 10 minutes, and then heat and oxidize it at a temperature of 65°C for 2 hours, discharge the material, wash it with deionized water for 3 times, and then drying the washed aramid fiber to constant weight to obtain oxidized aramid fiber;

[0043] In parts by weight, successively take 10 parts of graphene oxide, 80 parts of deionized water, and 4 parts of sodium polystyrene sulfonate, first dissolve sodium polystyrene sulfonate in deionized water, then add graphene oxide, and Under the condition of ultrasonic frequency of 40kHz, after ultrasonic dispersion for 10 minutes, spray drying to obtain pretreated graphene oxide; ...

Embodiment 2

[0050] Move the aramid fiber into the plasma reactor, and in an oxygen atmosphere, control the oxygen pressure to 50Pa, and the oxygen flow rate to 9mL / min, and plasma treat it for 25 minutes to obtain the plasma treated aramid fiber;

[0051] Add the plasma-treated aramid fiber into the sodium periodate solution with a mass fraction of 8%, stir and mix for 15 minutes, and then heat and oxidize it at a temperature of 68°C for 2.5 hours, discharge the material, and wash it with deionized water for 4 times. Then dry the washed aramid fiber to constant weight to obtain oxidized aramid fiber;

[0052] In parts by weight, successively take 20 parts of graphene oxide, 100 parts of deionized water, and 5 parts of sodium polystyrene sulfonate, first dissolve sodium polystyrene sulfonate in deionized water, then add graphene oxide, and Under the condition of ultrasonic frequency of 50kHz, after ultrasonic dispersion for 20 minutes, spray drying to obtain pretreated graphene oxide;

[...

Embodiment 3

[0059] Move the aramid fiber into the plasma reactor, and in an oxygen atmosphere, control the oxygen pressure to 60Pa, and the oxygen flow rate to 10mL / min, and plasma treat it for 30 minutes to obtain the plasma treated aramid fiber;

[0060] Add the plasma-treated aramid fiber into the sodium periodate solution with a mass fraction of 15%, stir and mix for 20 minutes, and then heat and oxidize it at a temperature of 75°C for 3 hours, discharge the material, wash it with deionized water for 5 times, and then drying the washed aramid fiber to constant weight to obtain oxidized aramid fiber;

[0061] In parts by weight, successively take 30 parts of graphene oxide, 120 parts of deionized water, and 6 parts of sodium polystyrene sulfonate, first dissolve sodium polystyrene sulfonate in deionized water, then add graphene oxide, and Under the condition of ultrasonic frequency of 60kHz, after ultrasonic dispersion for 30 minutes, it was spray-dried to obtain pretreated graphene ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com