Bolometer based on two-dimensional bismuth-oxygen-selenium film and preparation method of bolometer

A technology for measuring bolometer and bismuth oxygen, which is applied in the field of uncooled infrared detectors, and can solve the problem that the temperature coefficient of resistance of bolometer detectors, the low thermoelectric responsivity of bolometer emissivity coefficients, which affect the application of bolometer detectors, and the thermal Due to the low photothermoelectric responsivity of varistor materials, the effects of low electron surface concentration, excellent thermal radiation response performance, and high resistance temperature coefficient are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

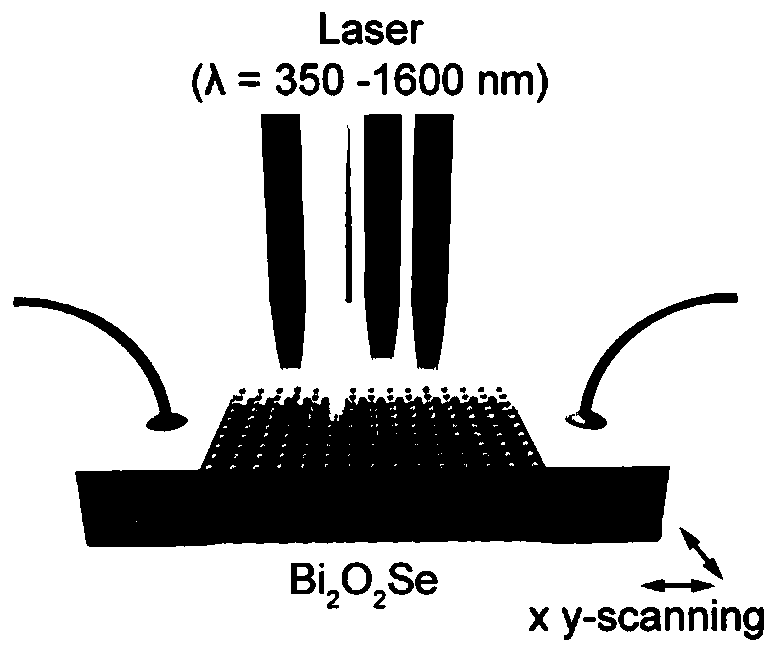

[0043] Such as Figure 6 The flow shown is a method for preparing a bolometer based on a two-dimensional bismuth oxide selenide thin film, comprising the following steps:

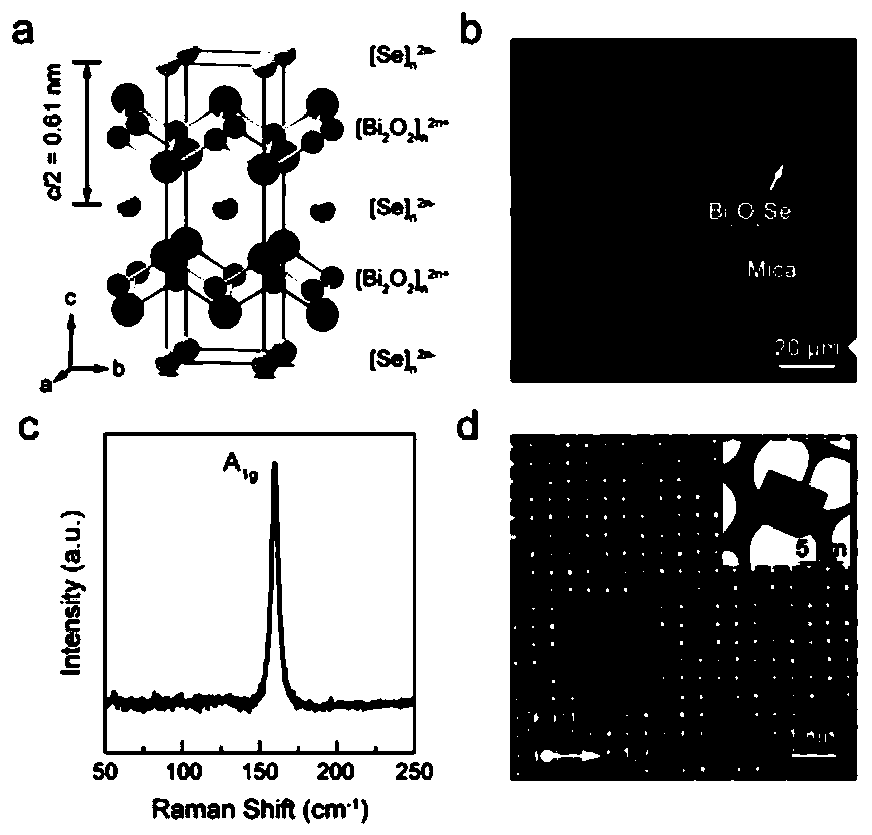

[0044] 1. Synthesis of two-dimensional bismuth oxyselenium film by chemical vapor deposition method: the precursor Bi containing bismuth and selenium 2 o 3 and Bi 2 Se 3 The molar ratio is 1:1, and it is placed in the upstream end area of the reaction furnace in the airflow direction. Subsequently, the mica substrate was placed 12 cm away from the center of the tube furnace, argon gas was introduced, the system pressure was maintained at 50 Torr, the temperature was raised to 680 ° C, the heating rate was 30 ° C / min, and the temperature was maintained for 60 min. Chemical vapor deposition was carried out. After the completion, the supply of the carrier gas was stopped, the temperature was naturally lowered to room temperature 25° C., and the mica substrate deposited with the bismuth oxyselenide film...

Embodiment 2

[0049] Such as Figure 6 The flow shown is a method for preparing a bolometer based on a two-dimensional bismuth oxide selenide thin film, comprising the following steps:

[0050] 1. Synthesis of two-dimensional bismuth oxyselenium film by chemical vapor deposition method: the precursor Bi containing bismuth and selenium 2 o 3 and Bi 2 Se 3 The molar ratio is 3:1, and it is placed in the upstream end area of the reaction furnace in the gas flow direction. Subsequently, the mica substrate was placed 14 cm away from the center of the tube furnace, nitrogen gas was introduced, the system pressure was maintained at 52 Torr, the temperature was raised to 720 ° C, the heating rate was 35 ° C / min, and the temperature was maintained for 65 min. Chemical vapor deposition was carried out. After completion, the supply of carrier gas was stopped, the temperature was naturally lowered to room temperature 27°C, and the mica substrate deposited with the bismuth oxyselenide film was t...

Embodiment 3

[0055] Such as Figure 6 The flow shown is a method for preparing a bolometer based on a two-dimensional bismuth oxide selenide thin film, comprising the following steps:

[0056] 1. Synthesis of two-dimensional bismuth oxyselenium film by chemical vapor deposition method: the precursor Bi containing bismuth and selenium 2 o 3 and Bi 2 Se 3 The molar ratio is 2:1, and it is placed in the upstream end area of the reaction furnace in the gas flow direction. Subsequently, the mica substrate was placed 10 cm away from the center of the tube furnace, nitrogen gas was introduced, the system pressure was maintained at 48 Torr, the temperature was raised to 640 ° C, the heating rate was 25 ° C / min, and the temperature was maintained for 65 min. Chemical vapor deposition was carried out and the deposition was completed. Afterwards, the supply of the carrier gas was stopped, and the temperature was naturally lowered to room temperature of 23° C., and the mica substrate deposited...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com