Sulfonium onium salt photoacid generator containing cedrol structure and preparation method thereof

A technology of photoacid generator, cedar alcohol, applied in the field of photoresist, to reduce edge roughness, increase fat solubility, and have the effect of broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

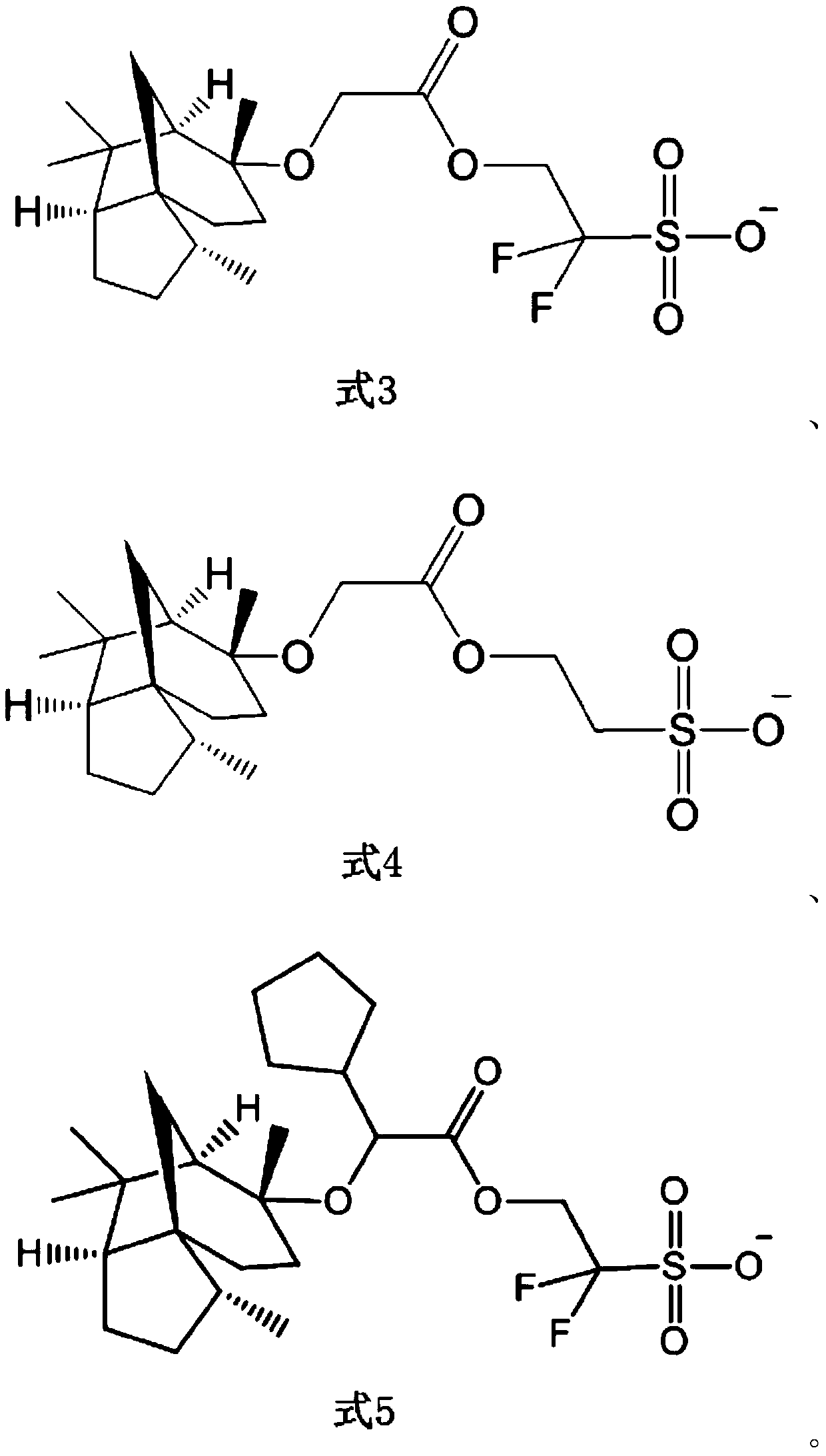

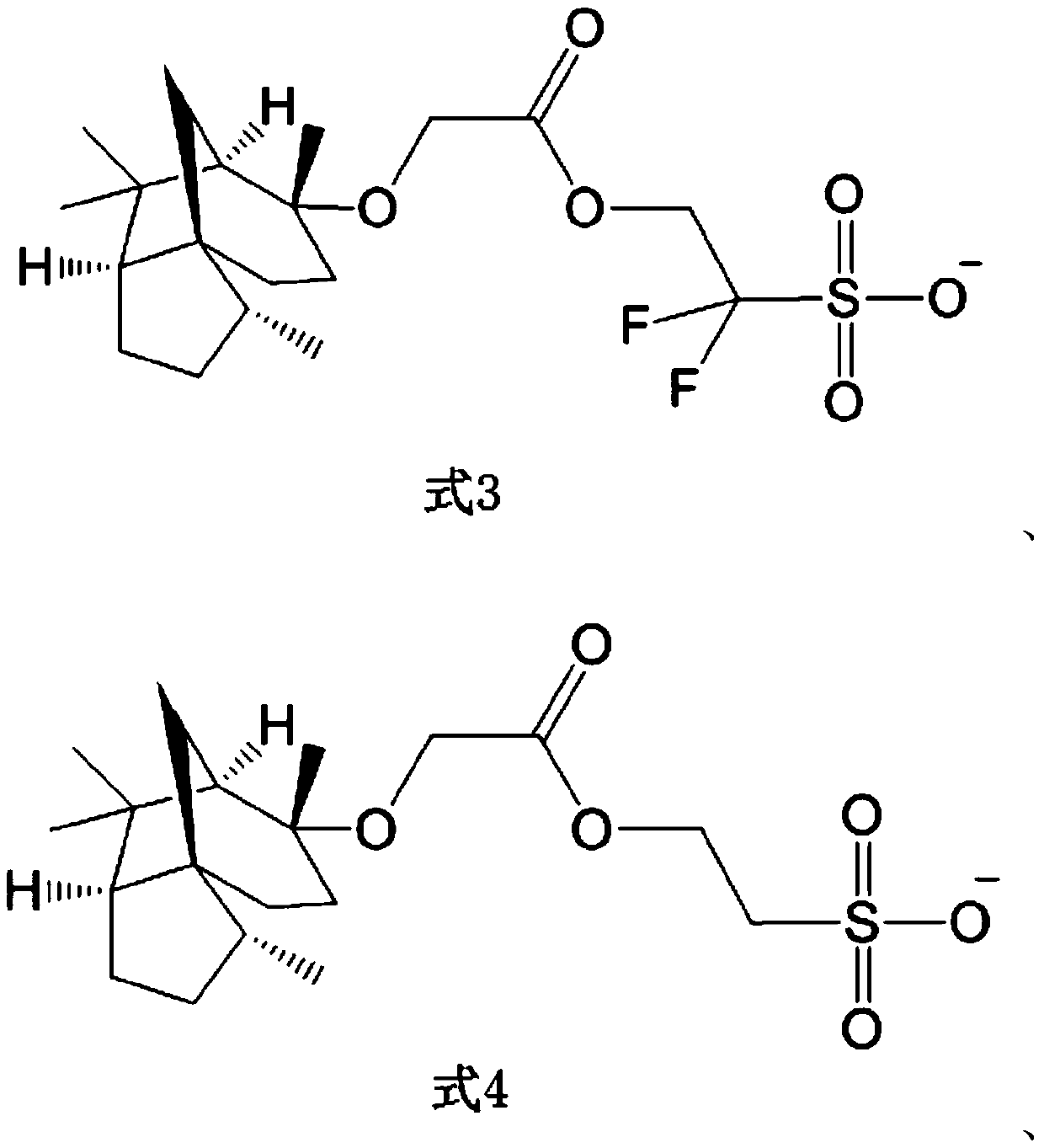

Image

Examples

Embodiment 1

[0032] A sulfonium salt photoacid generator 1-8 containing a cedaryl alcohol structure, the specific synthesis steps are as follows:

[0033] 1) Under nitrogen at 0°C, sodium hydride (1.25mol, 30g) was slowly added to a mixture of cedaryl alcohol 1-1 (0.899mol, 200g) and tetrahydrofuran (2000g), and stirred for 20 minutes; then ethyl bromoacetate Ester 1-2 (0.928mol, 155g) was added dropwise to the above mixture, stirred for 20 minutes; then stirred at 25°C for 6 hours; after the reaction was completed, quenched with water at 0°C; the quenched mixture Concentrate by rotary evaporation, extract with dichloromethane (700g×3); combine the extracts, wash with saturated brine (1000g), dry over anhydrous sodium sulfate, and concentrate by rotary evaporation to obtain a crude product; the crude product is purified by column chromatography to obtain a liquid Cederyl alcohol-containing ester compounds 1-3 (0.778mol, 240g, yield 86.5%).

[0034] 2) The ester compound 1-3 (0.648mol, 200...

Embodiment 2

[0040] A sulfonium salt photoacid generator 2-8 containing a cederyl alcohol structure, the specific synthesis steps are as follows:

[0041]1) Under nitrogen at 0°C, sodium hydride (1.25mol, 30g) was slowly added to a mixture of cedaryl alcohol 2-1 (0.899mol, 200g) and tetrahydrofuran (2000g), and stirred for 20 minutes; then ethyl chloroacetate Ester 2-2 (0.938mol, 115g) was added dropwise to the above mixture, stirred for 20 minutes; then stirred at 25°C for 6 hours; after the reaction was completed, quenched with water at 0°C, and the quenched mixture Concentrate by rotary evaporation, extract with dichloromethane (700g×3); combine the extracts, wash with saturated brine (1000g), dry over anhydrous sodium sulfate, and concentrate by rotary evaporation to obtain a crude product; the crude product is purified by column chromatography to obtain a liquid Cederyl alcohol-containing ester compound 2-3 (0.762mol, 235g, yield 84.7%).

[0042] 2) The ester compound 2-3 (0.648mol, ...

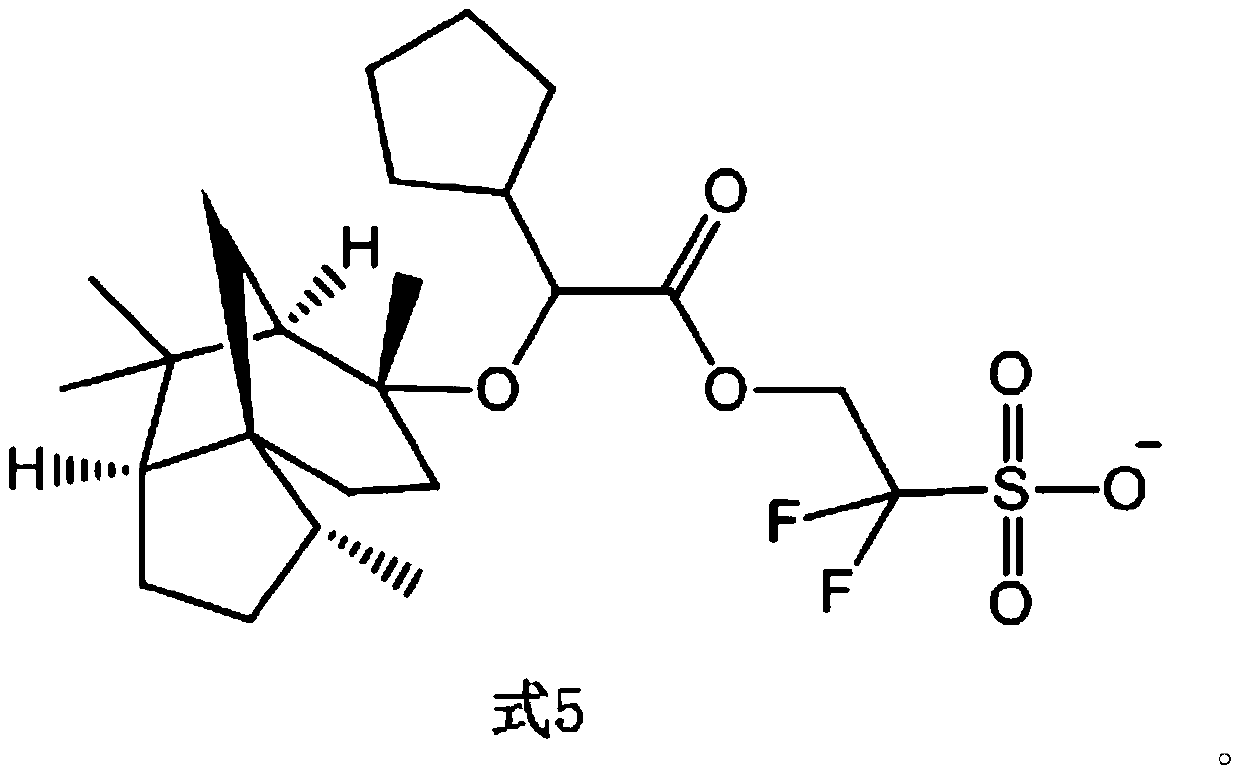

Embodiment 3

[0048] A sulfonium salt photoacid generator 3-8 containing a cederyl alcohol structure, the specific synthesis steps are as follows:

[0049] 1) Under nitrogen at 0°C, sodium hydride (1.25mol, 30g) was slowly added to a mixture of cedaryl alcohol 3-1 (0.899mol, 200g) and tetrahydrofuran (3000g), and stirred for 20 minutes; then 2-bromo - Ethyl 2-cyclopentyl acetate 3-2 (0.915mol, 215g) was added dropwise to the above mixture, stirred for 20 minutes; then stirred at 25°C for 6 hours; after the reaction was completed, quenched with water at 0°C The quenched mixed solution was concentrated by rotary evaporation and extracted with dichloromethane (700g×3); the combined extracts were washed with saturated brine (1000g), dried over anhydrous sodium sulfate, and concentrated by rotary evaporation to obtain a crude product; The product was purified by column chromatography to obtain a liquid ester compound 3-3 (0.717mol, 270g, yield 79.7%) containing cederyl alcohol structure.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com