Modified solid waste red mud catalyst and preparation method and application thereof

A solid waste and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of loose structure, poor apparent performance, uneven particle size distribution, etc., to improve the activity and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

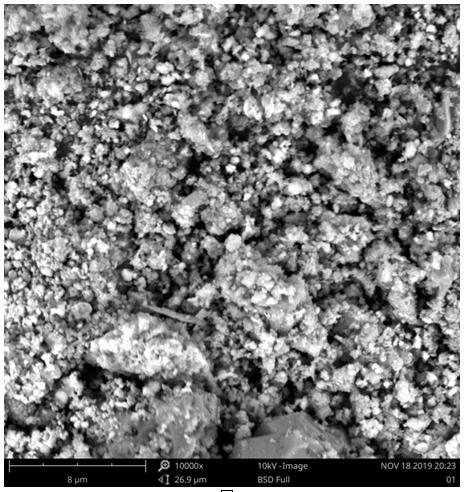

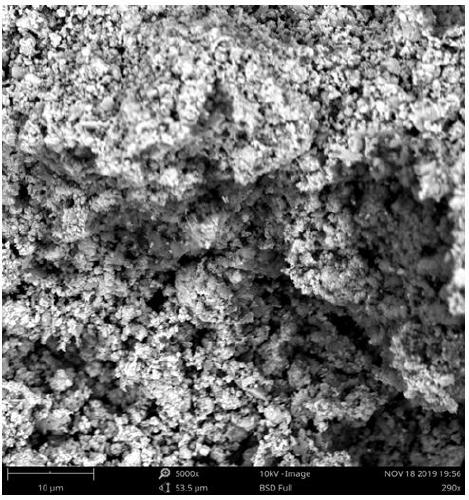

Image

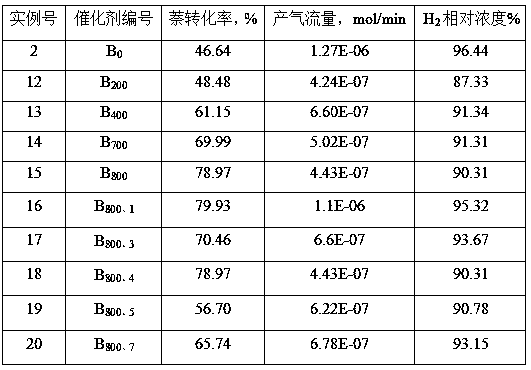

Examples

preparation example Construction

[0033] The preparation method of catalyst of the present invention comprises the steps:

[0034] (1) After drying the sieved red mud raw material, add a certain proportion of deionized water and mix it fully under magnetic stirring; then add a certain concentration of acidic solution to adjust the pH of the mixture; under the condition of heating in a water bath make it fully responsive;

[0035] (2) Naturally cool down to a certain temperature after the reaction is completed; after a period of constant temperature aging, wait for it to drop to room temperature; add alkaline solution to the mixture at room temperature; filter it and wash it with deionized water. Physically compress and dry, and finally grind and sieve the particles;

[0036] (3) Roast the prepared particle samples in the air to obtain the red mud catalyst.

[0037] Step (1) is to grind the red mud raw material, take small particles below 1000 μm and place them in a drying oven at 105 °C for 5 hours to make t...

Embodiment 1

[0049] Weigh 40 g of dried Guangxi red mud raw materials with a particle size of less than 1000 μm, and the moisture content is 5% in terms of mass percentage. Place it in a 500 ml round bottom flask, add 120 g of deionized water to it and stir on a magnetic stirrer at 800 r / min for half an hour. After stirring, add 6 mol / L hydrochloric acid and shake it until the pH is 2, then place the flask in a water bath at 85°C and heat for 2 hours. After the reaction, the mixture was aged in a water bath at 50 °C for 1 h, then naturally cooled to room temperature, and saturated sodium hydroxide solution was added dropwise to the mixture until the pH of the mixture was neutral. The resulting mixture was filtered with suction and washed with deionized water. The product obtained by suction filtration and washing was dried in an oven at 80 °C for 0.5 hours, then placed in a manual physical compressor, compressed into strips, and then dried at 105 °C for 6 hours to completely dehydrate. T...

Embodiment 2

[0051] Weigh 40 g of Inner Mongolia red mud raw material with a particle size of less than 1000 μm after drying, and the moisture content is 5% in terms of mass percentage. Place it in a 500 ml round bottom flask, add 120 g of deionized water to it and stir on a magnetic stirrer at 800 r / min for half an hour. After stirring, add nitric acid solution with a mass fraction of 22% and shake until the pH is 1, then place the flask in a water bath at 85 °C and heat it for 4 hours. After the reaction, the mixture was aged in a water bath at 50 °C for 1 h, then naturally cooled to room temperature, and saturated sodium hydroxide solution was added dropwise to the mixture until the pH of the mixture was neutral. The resulting mixture was filtered with suction and washed with deionized water. The product obtained by suction filtration and washing was dried in an oven at 80 °C for 0.5 hours, then placed in a manual physical compressor, compressed into strips, and then dried at 105 °C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com