A kind of plugging and anti-collapse treatment agent for shale formation and preparation method thereof

A technology for plugging anti-slump and treatment agents, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of uncontrollable fixed material size, affecting pump pressure stability, poor temperature resistance, etc., and achieves production Low cost, stable product quality, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Into a 500mL there-necked bottle for three times, add 50g C9 petroleum resin, 20g polyethylene glycol (molecular weight 500), 10g polyether modified trisiloxane, add 100mL 1,2-dichloroethane, stir Until each component is fully dispersed, control the temperature at 10°C, add 0.1g of palladium chloride catalyst, react for 1h, add 1g of sulfur, continue the reaction for 1h, use vacuum distillation technology to recover the organic solvent, dry and pulverize the residue to obtain 75g The yellow powder is the plugging and anti-collapse treatment agent for the shale formation.

Embodiment 2

[0028] After pumping and exchanging air three times into a 1000mL three-necked bottle, add 150g C5 petroleum resin, 10g polyethylene glycol (molecular weight 1000), 20g vinyl triperoxy tert-butylsilane, add 300mL carbon tetrachloride, and stir until each group Fully disperse, control the temperature at 30°C, add 0.05g of rhodium chloride catalyst, react for 3 hours, add 10g of thiourea, continue to react for 24 hours, use vacuum distillation technology to recover the organic solvent, dry and pulverize the residue to obtain 165g of yellow powder , which is the plugging and anti-collapse treatment agent for the shale formation.

Embodiment 3

[0030] Into a 1000mL three-necked bottle, after pumping and exchanging air three times, add 100g of C9 petroleum resin and 20g of coumarone resin, 50g of polyethylene glycol (molecular weight 2000), 10g of polyether modified dimethyl siloxane and, add 200mL Ethyl acetate and 100mL chloroform, stir until the components are fully dispersed, control the temperature at 30°C, add 0.05g of rhodium chloride catalyst, react for 3 hours, add 10g of thiourea, continue the reaction for 24 hours, and use vacuum distillation technology to recover the organic solvent , dry and pulverize the residue to obtain 165g of yellow powder, which is the plugging and anti-collapse treatment agent for the shale formation.

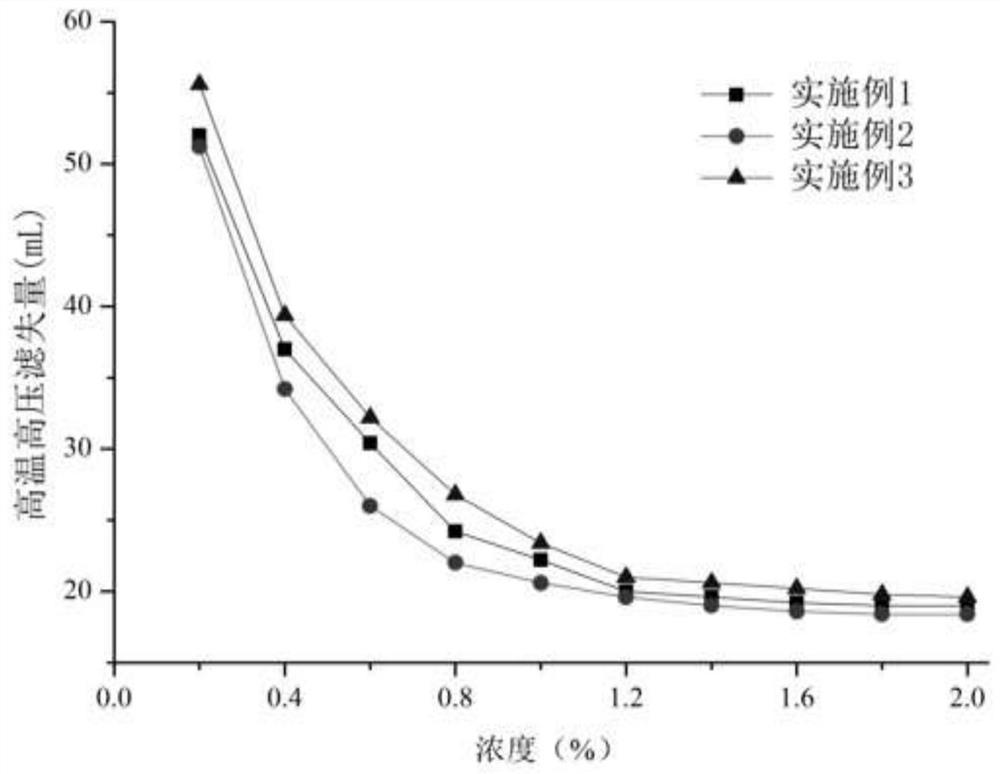

[0031] Plugging performance evaluation

[0032] Determination of filtration loss at high temperature and high pressure (test temperature: 150°C)

[0033] Divide the treatment agent in Examples 1 to 3 into several parts, and add to 4% drilling fluid base slurry respectively (the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com