A ti-doped cdin 2 the s 4 Intermediate zone film and preparation method thereof

A ti-cdin2s4, thin film preparation technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, to achieve uniform size distribution, improve light absorption intensity, and enhance the effect of photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

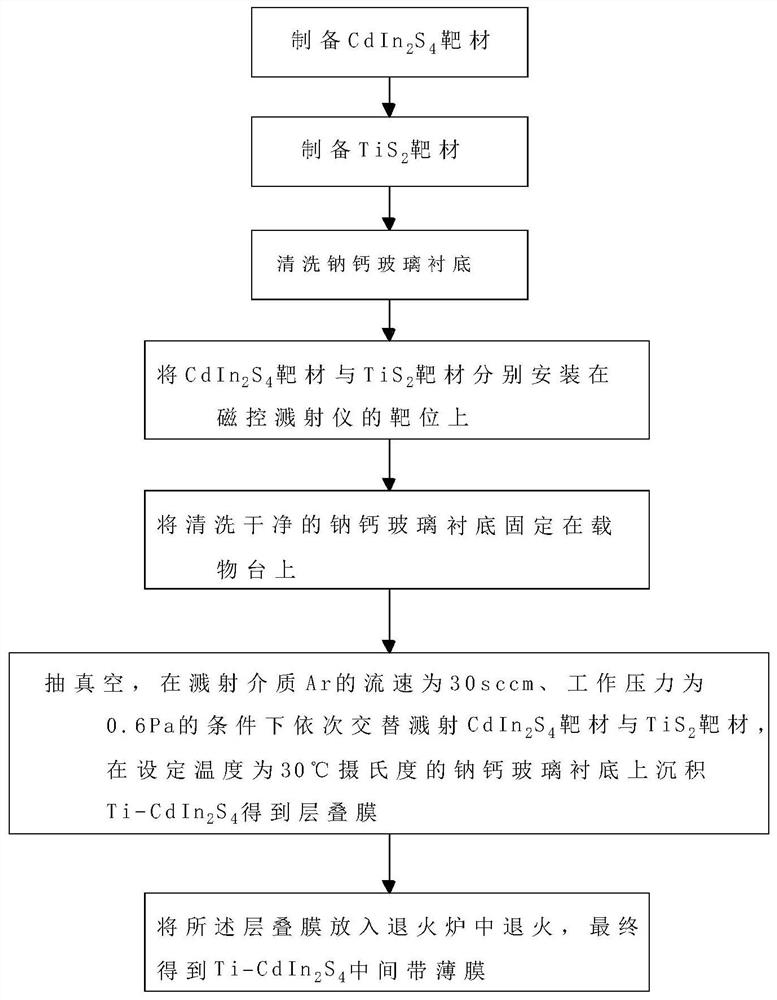

[0053] see figure 1 , a Ti-doped CdIn of this embodiment 2 S 4 The preparation method of intermediate zone film, its method step is as follows:

[0054] Step 1: Preparation of CdIn 2 S 4 Target: choose a circular target with a diameter of 65mm, a purity of 99.99%, and a thickness of 5mm.

[0055] Step 2: Preparation of TiS 2 Target material; select TiS with a thickness of 3mm and a purity of 99.99% 2 .

[0056] Step 3: Clean the soda-lime glass substrate, first cut the soda-lime glass substrate into 2cm×2cm, clean the surface dirt and debris with detergent, then ultrasonically use deionized water for 20min, and then soak in 10% dilute sulfuric acid After 20 minutes, take out the soda-lime glass substrate and clean it with deionized water; put the cleaned soda-lime glass substrate into carbon tetrachloride, acetone, and absolute ethanol in turn for 10 minutes; finally put the soda-lime glass substrate completed by ultrasonic Put the bottom into absolute ethanol for late...

Embodiment 2

[0064] For the preparation process, please refer to figure 1 , a Ti-doped CdIn of this embodiment 2 S 4 The preparation method of the intermediate zone film, its method steps and embodiment 1 are basically the same, the difference is that in step 4 Ti-CdIn 2 S 4 Fabrication of intermediate zone films, sputtering CdIn 2 S 4 A total of 6 layers, each layer sputtering time 10min, TiS 2 There are 5 layers in total, and the sputtering time for each layer is 1.5min; it is used as a prefabricated laminated film sample labeled T-CIS2.

Embodiment 3

[0066] For the preparation process, please refer to figure 1 , a Ti-doped CdIn of this embodiment 2 S 4 The preparation method of the intermediate zone film, its method steps and embodiment 1 are basically the same, the difference is that in step 4 Ti-CdIn 2 S 4 Fabrication of intermediate zone films, sputtering CdIn 2 S 4 A total of 6 layers, each layer sputtering time 10min, TiS 2 A total of 5 layers, each sputtering time 2.5min. As a prefabricated laminated film sample of the designation T-CIS3.

[0067] On the basis of the above examples, the sputtering method was used to prepare CdIn 2 S 4 A prefabricated film with a total of 6 layers, and the sputtering time of each layer is 11 minutes; it is used as a comparison film sample.

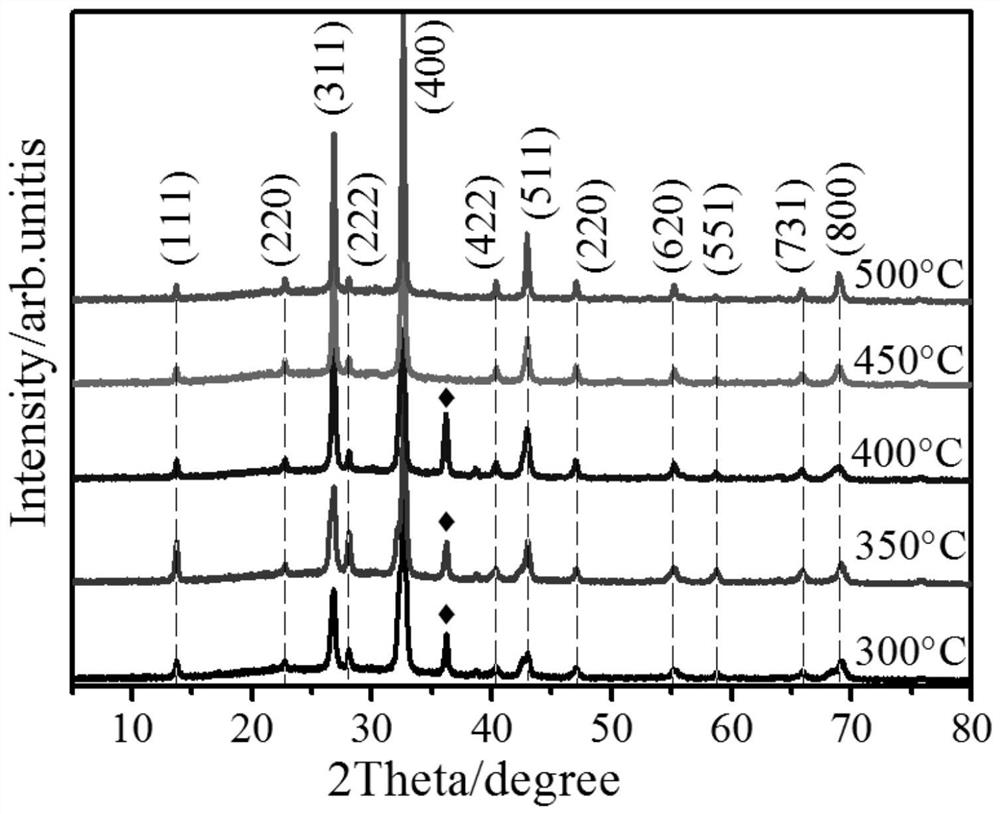

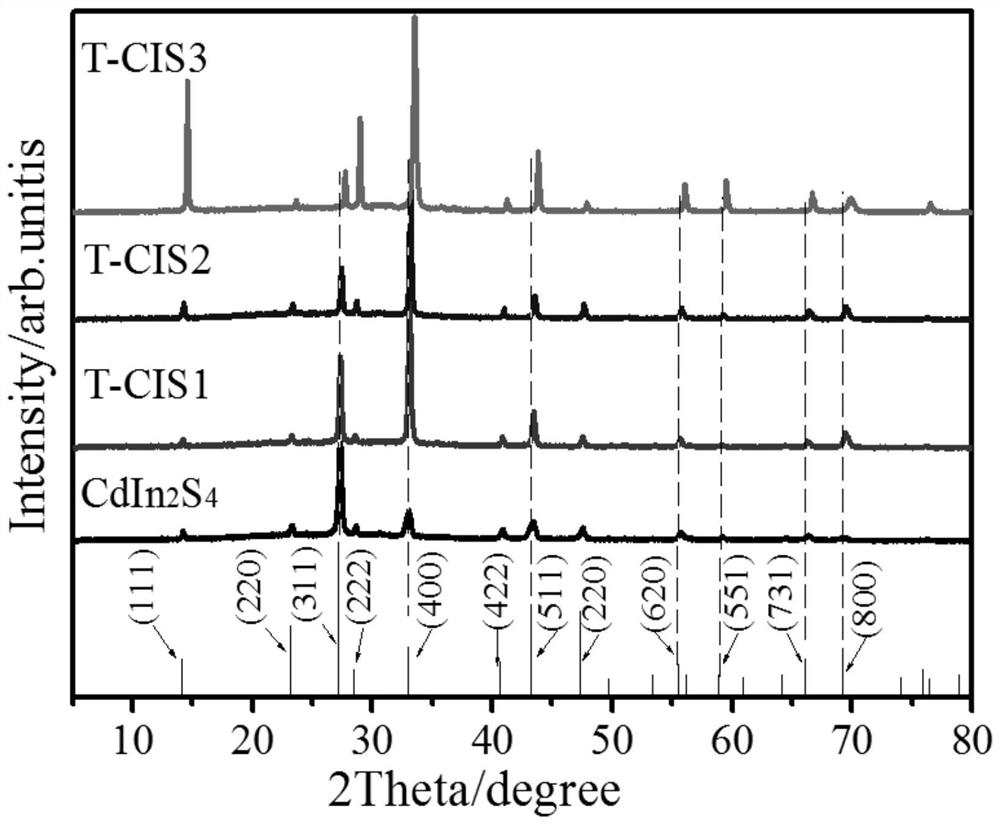

[0068] For the obtained Ti-CdIn 2 S 4 The middle zone film is analyzed by X-ray diffractometer (hereinafter referred to as: XRD), and the crystallinity and crystal structure of the film sample are characterized and qualitatively analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com