Microfiber-functionalized cellulose forming paper with the functions of carrying aroma and selectively reducing phenol content in smoke and its preparation and application

An ultra-fine fiber and selective technology, applied in fiber treatment, non-fiber pulp addition, filament/thread forming, etc., can solve the problems of increasing the preparation process and cost, reducing harm, affecting the combustion performance of cigarettes, etc., to achieve outstanding selection Sex-reducing effect, effect of unique fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

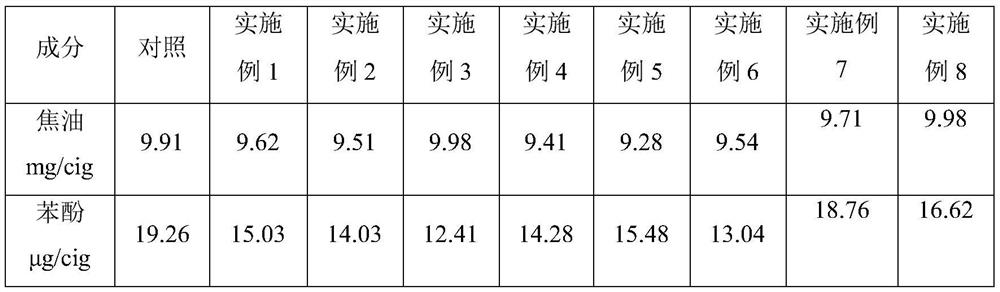

Embodiment 1

[0045] Preparation of electrospun cellulose forming paper with fragrance-carrying microfiber function

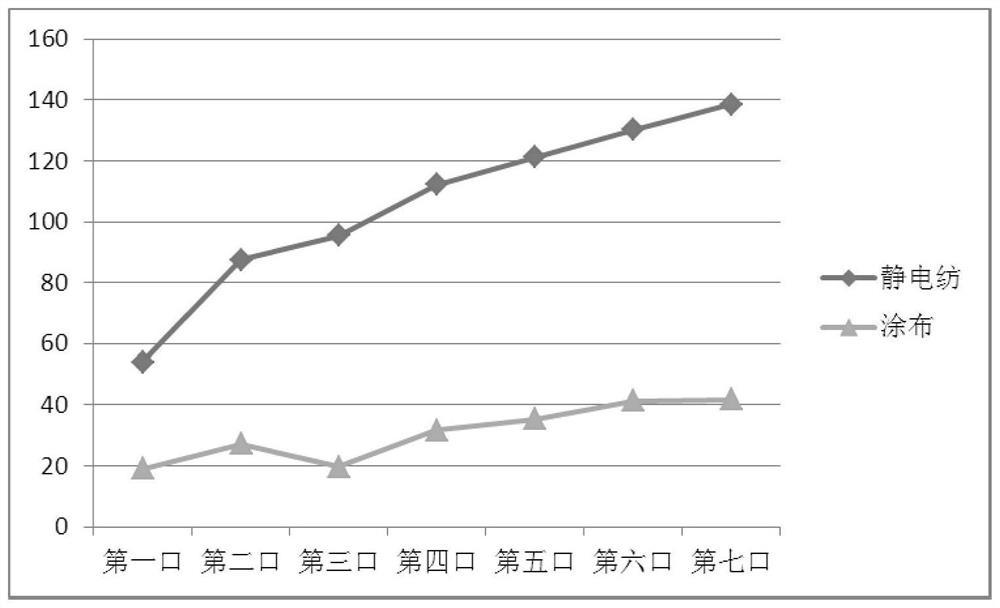

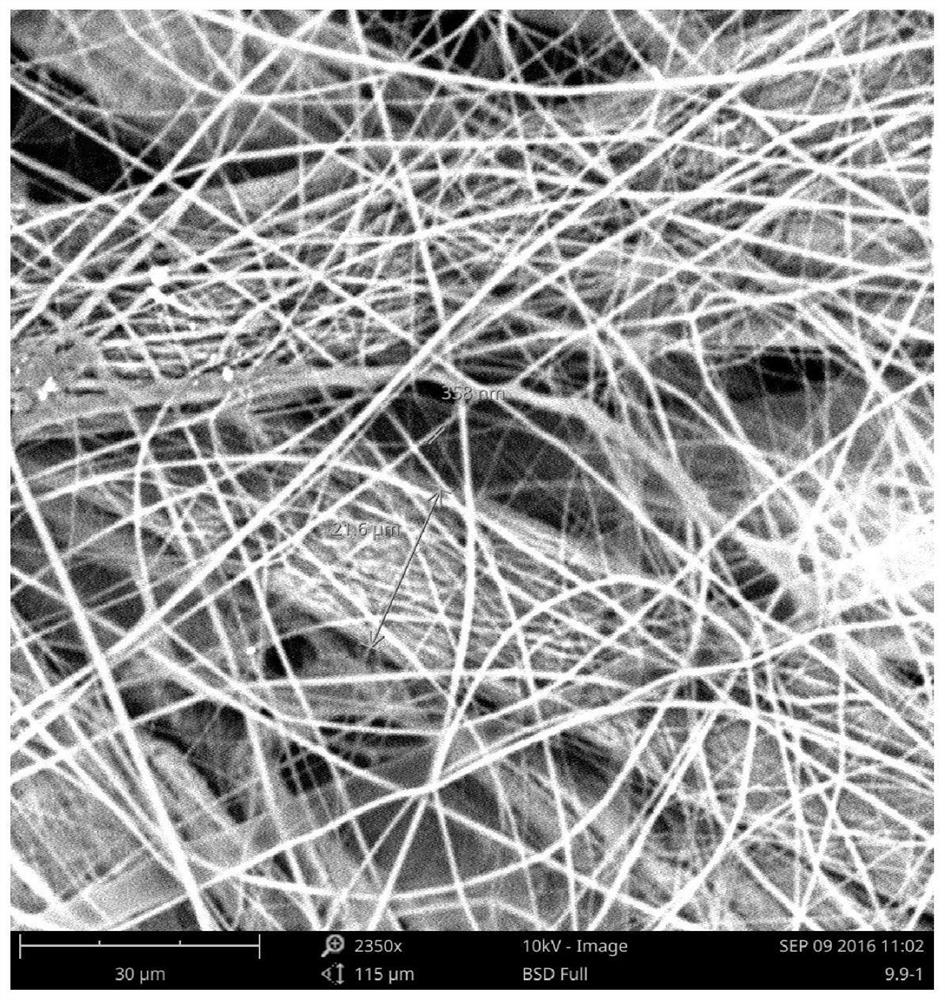

[0046] Electrospinning was performed in an electrospinning chamber. Mix menthol and menthone in a mass ratio of 30:70 to form a mint substance, then mix polyvinylpyrrolidone K30 with a mint substance in a mass ratio of 70:30 to form a spinnable material, and then mix the spinnable material with solvent ethanol in a mass ratio of 70:30. Mixing at a ratio of 15:85, stirring continuously for 5 hours in a constant temperature water bath at 50 °C to obtain a uniform spinnable solution, placing it in a storage tank, and feeding the liquid to 80 electrospinning nozzles through a micro pump at a speed of 4 mL / h per nozzle. Supply, the electrospinning voltage is 15KV, the distance between the nozzle and the paper base is 10cm, the electrospinning environment temperature is 28°C, each group of electrospinning nozzles is 20 nozzles, each group of nozzles forms a loop, and each group of...

Embodiment 2

[0050] Preparation of electrospun cellulose forming paper with fragrance-carrying microfiber function

[0051] Electrospinning was performed in the electrospinning chamber in Example 1. The spinning equipment was the same as in Example 1.

[0052] Mix menthol and menthone with a mass ratio of 40:60 to form a mint substance, then mix polyvinylpyrrolidone K60 with a mint substance in a mass ratio of 70:30 to form a spinnable material, and then mix the spinnable material with solvent ethanol with a mass ratio of 70:30. Mixing at a ratio of 15:85, stirring continuously for 5 hours in a constant temperature water bath at 50 °C to obtain a uniform spinnable solution, at room temperature, using a voltage of 20KV and a receiving distance of 10cm, the spinning solution advancing speed of 3ml / h, prepared on cellulose paper. The ultrafine fibers with a diameter of about 610nm have fragrance-carrying fibers, and the spraying amount of the ultrafine fibers on the cellulose paper substrate...

Embodiment 3

[0056] Preparation of electrospun cellulose forming paper with fragrance-carrying microfiber function

[0057] Electrospinning was performed in the electrospinning chamber in Example 1. The spinning equipment was the same as in Example 1.

[0058] Mix menthol and menthone in a mass ratio of 50:50 to form a mint substance, then mix polyvinylpyrrolidone K90 and mint substance in a mass ratio of 60:40 to form a spinnable material, and then mix the spinnable material with solvent ethanol in a mass ratio of 60:40. Mixing at a ratio of 20:80, stirring continuously for 5h in a constant temperature water bath at 50°C to obtain a uniform spinnable solution, at room temperature, using a voltage of 25KV and a receiving distance of 15cm, the spinning solution advancing speed of 3.5ml / h, prepared on cellulose paper Fragrance-carrying ultrafine fibers with a diameter of about 700nm are produced, and the spray coating amount of the ultrafine fibers on the cellulose paper substrate is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com