Graphene-aluminum composite wire and preparation method thereof

An aluminum composite, graphene technology, applied in the direction of metal/alloy conductors, carbon-silicon compound conductors, cable/conductor manufacturing, etc., can solve problems such as poor conductivity, reduce lattice mismatch rate, improve bonding, and improve grid matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

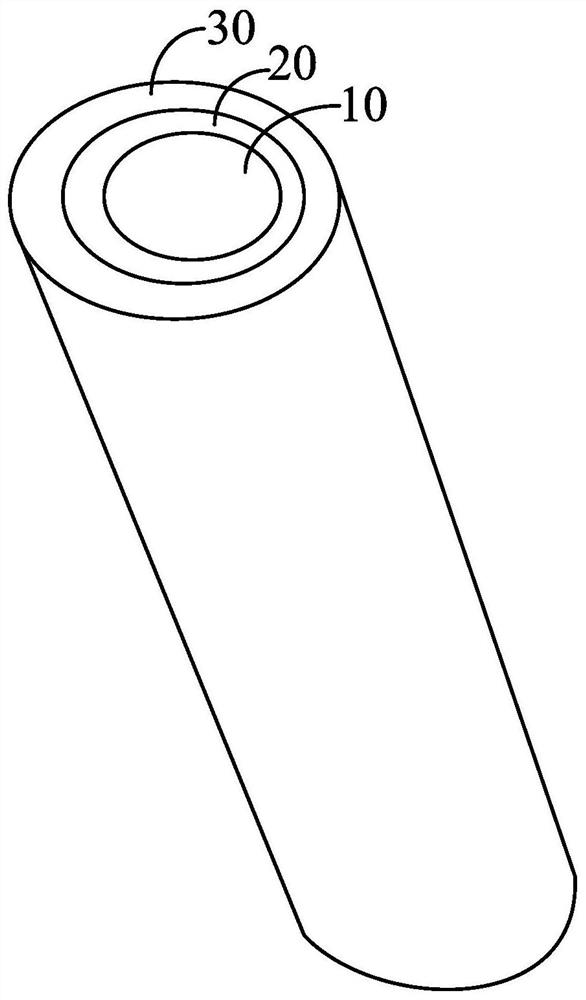

[0031] An embodiment of the present invention also provides a method for preparing the graphene-aluminum composite wire, comprising:

[0032] S100, the intermediate metal layer 20 is formed on the surface of the aluminum base 10, and the intermediate metal layer 20 wraps the aluminum base 10 to obtain a double-layer structure; and

[0033] S200 , the graphene layer 30 is formed on the intermediate metal layer 20 by a plasma chemical vapor deposition method.

[0034] In step S100, the method for forming the intermediate metal layer 20 may be electroplating or magnetron sputtering. The electroplating method is a process of plating an intermediate metal thin layer on the surface of the aluminum base 10 by electrolysis. During electroplating, the plated metal (ie, the intermediate layer metal) is used as the anode, the workpiece to be plated (ie, the aluminum base 10) is used as the cathode. The cations are reduced on the surface of the workpiece to be plated to form a coating. ...

Embodiment 1

[0045]According to the formula of nickel sulfate 35g / L, sodium hypophosphite 25g / L, and lactic acid 30mg / L, the electroplating solution was prepared. At 60°C, the aluminum substrate 10, which was ultrasonically cleaned with alcohol at 100Hz for 1h, was placed in the electroplating solution for 40min. After being taken out, an intermediate metal layer 20 is formed on the surface of the aluminum substrate 10 to obtain a double-layer structure. The aluminum base body 10 has a diameter of 0.5 mm.

[0046] The double-layer structure was put into a vacuum tube furnace, the temperature was raised to 500° C., the plasma was turned on, the methane feeding amount was 5 sccm, the hydrogen feeding amount was 100 sccm, and the argon gas feeding amount was 200 sccm, and gradually formed on the intermediate metal layer 20 The graphene layer 30 is obtained to obtain a graphene-aluminum composite wire.

[0047] From the end of the vacuum tube furnace, the graphene-aluminum composite wire form...

Embodiment 2

[0050] According to the formula of copper sulfate 30g / L, sodium hypophosphite 20g / L, and lactic acid 35mg / L, the electroplating solution was prepared. At 60°C, the aluminum substrate 10, which was ultrasonically cleaned with alcohol at 100Hz for 1h, was placed in the electroplating solution for 40min. After being taken out, an intermediate metal layer 20 is formed on the surface of the aluminum substrate 10 to obtain a double-layer structure. The aluminum base body 10 has a diameter of 0.5 mm.

[0051] The double-layer structure was put into a vacuum tube furnace, the temperature was raised to 450° C., the plasma was turned on, the gaseous ethanol was fed in an amount of 20 sccm, the hydrogen inflow amount was 50 sccm, and the argon gas in-flow amount was 100 sccm, gradually on the intermediate metal layer 20 A graphene layer 30 is formed to obtain a graphene-aluminum composite wire.

[0052] From the end of the vacuum tube furnace, the graphene-aluminum composite wire formin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com