Silver-based catalyst, and preparation method and application thereof

A catalyst, silver-based technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limiting the popularization and application of precious metal catalysts, large loads, and high catalyst costs, and achieve good oxygen storage capacity. , low cost, good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

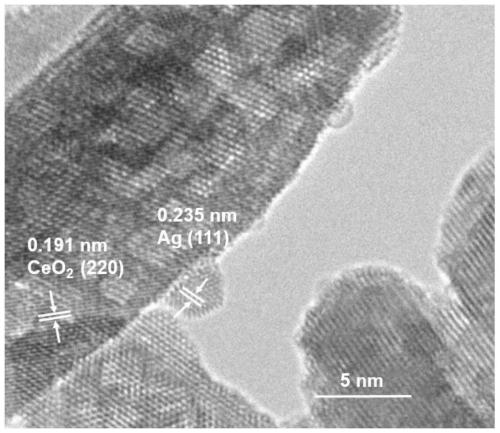

[0035] Precipitation and deposition: Pour 1.9g of cerium dioxide nanorods into the stirred silver nitrate aqueous solution, mix and stir for 30 minutes to obtain a mixed solution, use sodium hydroxide as a precipitating agent, and dropwise add sodium hydroxide aqueous solution to the mixed solution, Adjust the pH of the mixed solution to 10, and age in a water bath at 60° C. for 3 hours to obtain a precipitate. Wherein, the mass of silver nitrate contained in the silver nitrate aqueous solution is 0.1574g.

[0036] Calcination: filter the mixed solution containing the precipitate by centrifugation and wash away the residual sodium hydroxide, and dry it. The dried precipitate is calcined for 2 hours at 300°C with oxygen and nitrogen mixed gas to obtain the silver-loaded The catalyzer on the cerium oxide nanorod, namely silver-based catalyst, wherein the total mass of silver-based catalyst is 2g, and the loading of silver on the silver-based catalyst is 5wt%, and the loading of ...

Embodiment 2

[0040] This embodiment provides a silver-based catalyst. The difference between this embodiment and Embodiment 1 is that in the step of precipitation and deposition, aging is carried out in a water bath at 50° C., that is, the deposition temperature is 50° C.

Embodiment 3

[0042] This embodiment provides a silver-based catalyst. The difference between this embodiment and Embodiment 1 is that the pH of the mixed solution is adjusted to 9 during the precipitation deposition step. Although silver-based catalysts can also be obtained, under these conditions, the silver in the silver nitrate solution cannot be completely precipitated, resulting in less silver actually loaded onto the ceria nanorods, and the actual loading of silver is lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com