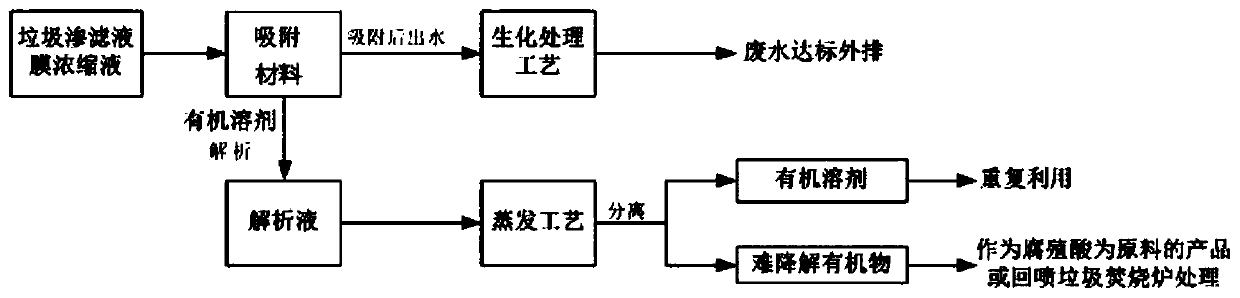

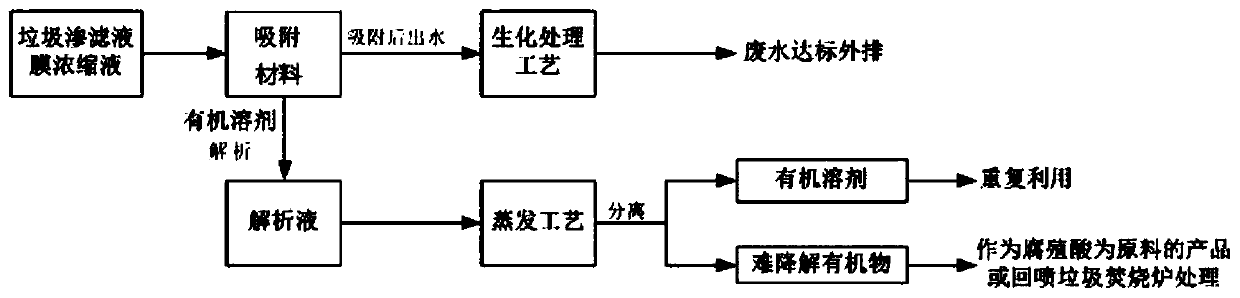

Landfill leachate membrane concentrated solution treatment process

A technology for landfill leachate and membrane concentration, which is applied in the treatment of polluted groundwater/leachate, osmotic/dialysis water/sewage treatment, water/sewage treatment, etc., to reduce costs, improve recycling rate, and enhance activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

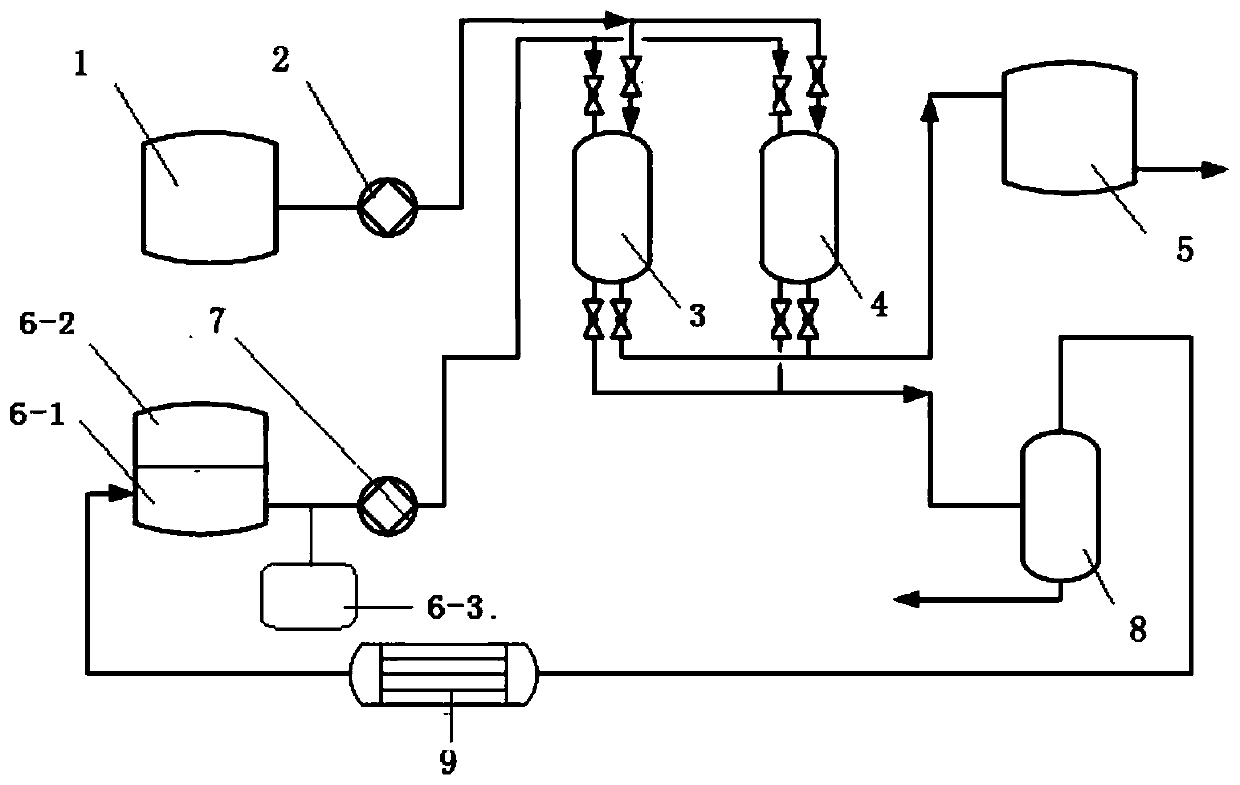

[0047] A process for treating landfill leachate membrane concentrate, comprising the following steps:

[0048] S1. Adding adsorption material: the leachate membrane concentrate is adsorbed by the adsorption material. After the leachate membrane concentrate is adsorbed, the effluent enters the biochemical treatment and is discharged after reaching the standard; the adsorption material includes macroporous resin and dialdehyde containing various active groups Modified dopamine macroporous resin. The adsorption material in S1 adopts multi-stage countercurrent adsorption layer by layer. The adsorption material in S1 is packed by columns, the filling rate is 85%, and the method of one for use and one for standby is adopted.

[0049] The microorganisms used in the biochemical treatment process are highly salt-tolerant strains.

[0050] S2. Add organic solvent and recover the adsorption material: after the organic matter adsorbed in the adsorption material reaches saturation, add a...

Embodiment 2

[0055] A process for treating landfill leachate membrane concentrate, comprising the following steps:

[0056] S1. Adding adsorption material: Adsorb the leachate membrane concentrate through the adsorption material. After the leachate membrane concentrate is adsorbed, the effluent enters the biochemical treatment and is discharged after reaching the standard; the adsorption material includes macroporous resin containing various active groups, dialdehyde The modified dopamine macroporous resin and aminated polyethylene glycol and pyromellitic anhydride are cross-linked and modified by dialdehyde polysaccharides, and are polymer adsorption materials synthesized by thermal condensation polymerization. The adsorption material in S1 adopts multi-stage countercurrent layer-by-layer adsorption, and the multi-stage counter-current layer-by-layer adsorption is 3-stage countercurrent adsorption; the adsorption material in S1 is filled in tanks, the filling rate is 50%, and the method of...

Embodiment 3

[0061] A process for treating landfill leachate membrane concentrate, comprising the following steps:

[0062] S1. Adding adsorption material: Adsorb the leachate membrane concentrate through the adsorption material. After the leachate membrane concentrate is adsorbed, the effluent enters the biochemical treatment and is discharged after reaching the standard; the adsorption material includes macroporous resin containing various active groups, dialdehyde Modified dopamine macroporous resin, aminated polyethylene glycol and pyromellitic anhydride are cross-linked and modified by dialdehyde polysaccharide, and are polymer adsorption materials synthesized by thermal condensation polymerization. The adsorption material in S1 adopts multi-stage countercurrent layer-by-layer adsorption, which is 5-stage countercurrent layer-by-layer adsorption. The adsorption material in S1 is filled with column and tank at the same time, and the filling rate of both column and tank is 100%.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com