Two-phase composite microwave dielectric ceramic material, and preparation method and application thereof

A technology of microwave dielectric ceramics and mixtures, applied in waveguide devices, resonators, circuits, etc., to achieve the effects of easy mass and stable industrial production, controllable synthesis process, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

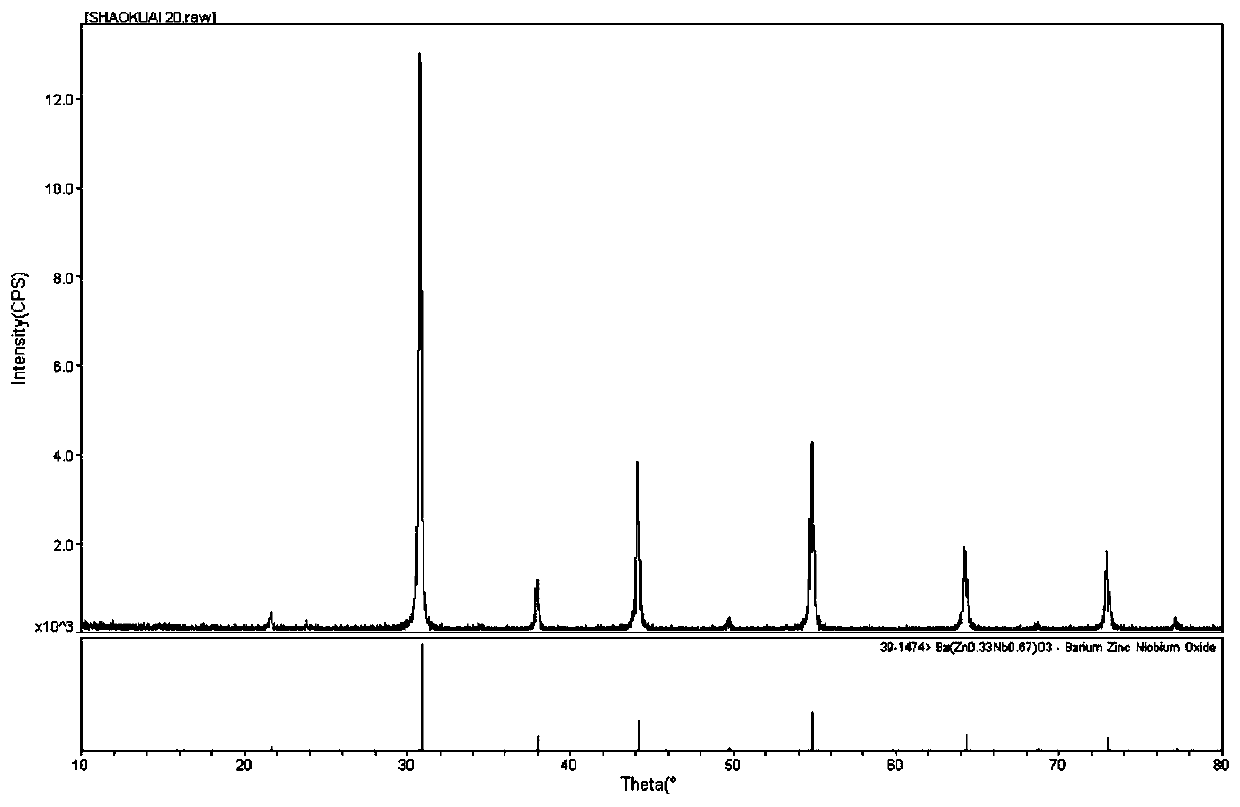

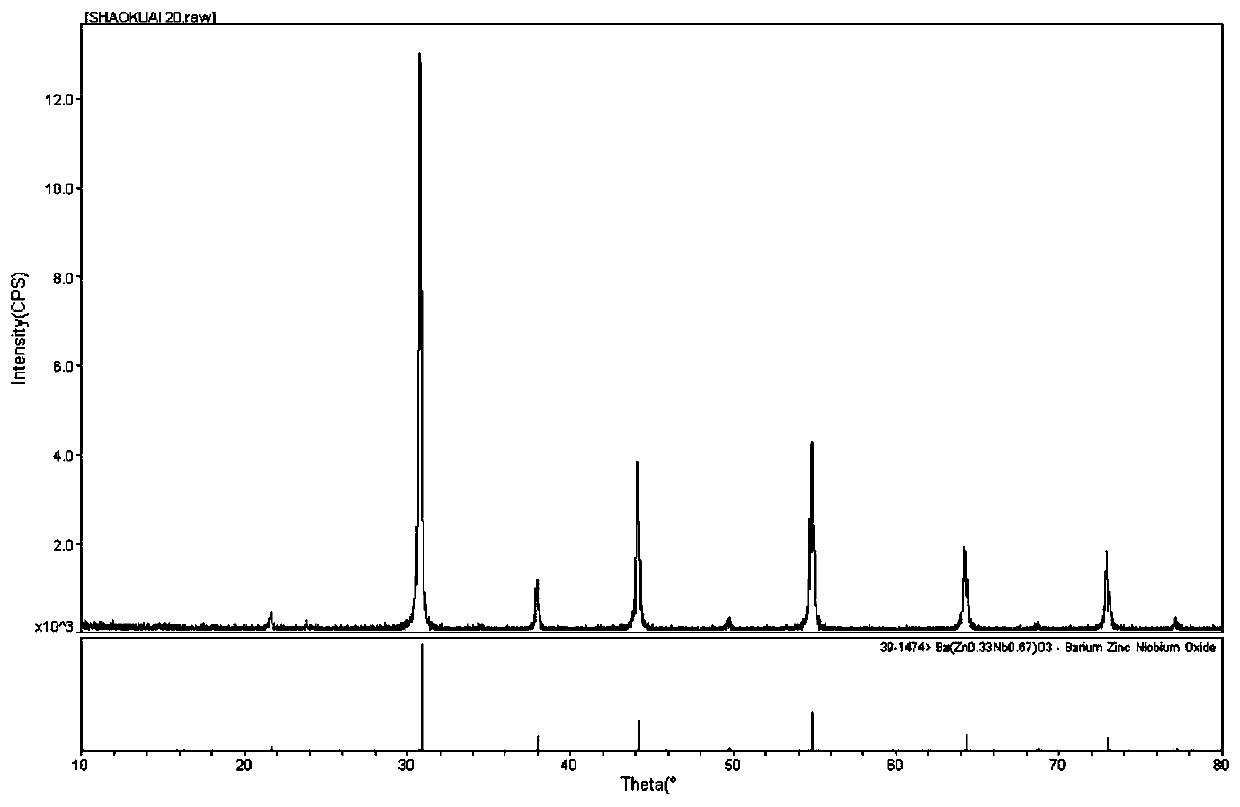

[0047] Take BaCO according to the molar ratio 1:(1 / 3):(1 / 3) 3 , ZnO, Nb 2 o 5 Mix the raw materials to obtain a mixture, then add water to the ball mill according to the amount of mixture: water = 1:0.8, and add ammonium acrylate dispersant accounting for 0.4wt% of the mixture, then add the mixture and mix evenly, ball mill 3h; the ball-milled slurry is sand-milled and dispersed by a sand mill; the dispersed material is microwave-dried by a microwave dryer until the water content of the material is 1 / 3 Nb 2 / 3 )O 3 ,spare. The Ba(Zn 1 / 3 Nb 2 / 3 )O 3 See attached XRD chart figure 1 As shown, it can be seen that the product is Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Pure phase and well synthesized.

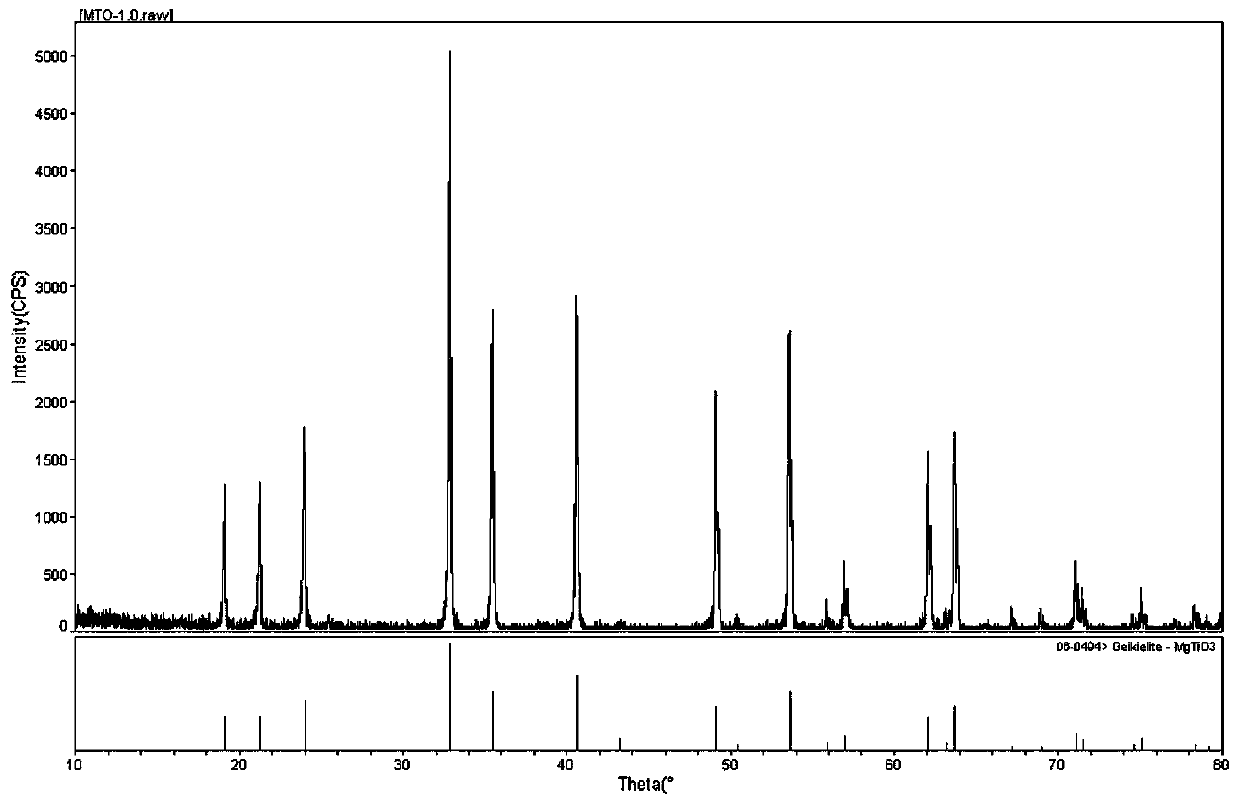

[0048] Take Mg(OH) according to the stoichiometric ratio of 1:1 2 and TiO 2 Mix the raw materials to obtain a mixture, then add water to the ball mill according to the amount of mixture: water = 1:1, and add ammonium acrylate dispersant accounting for 0.8wt% of the mixture, then add the mi...

Embodiment 2

[0053] Take BaCO according to the stoichiometric ratio 3 , ZnO, Nb 2 o 5 Mix the raw materials to obtain a mixture, then add water to the ball mill according to the amount of mixture: water = 1:0.4, and add ammonium acrylate dispersant accounting for 1.0 wt% of the mixture, then add the mixture and mix evenly, ball mill 3h; the ball-milled slurry is dispersed by sand milling with a sand mill; the dispersed material is microwave-dried using a microwave dryer until the water content of the material is 1 / 3 Nb 2 / 3 )O 3 ,spare.

[0054] Take Mg(OH) according to the stoichiometric ratio 2 and TiO 2 Mix the raw materials to obtain a mixture, then add water to the ball mill according to the amount of mixture: water = 1:0.8, and add ammonium acrylate dispersant accounting for 1.0 wt% of the mixture, then add the mixture and mix evenly, ball mill 3h; the ball-milled slurry is dispersed by sand milling with a sand mill; the dispersed material is microwave-dried using a microwave dr...

Embodiment 3

[0059] Take BaCO according to the stoichiometric ratio 3 , ZnO, Nb 2 o 5 Mix the raw materials to obtain a mixture, then add water to the ball mill according to the amount of mixture: water = 1:0.6, and add ammonium acrylate dispersant accounting for 0.8wt% of the mixture, then add the mixture and mix evenly, ball mill 3h; the ball-milled slurry was dispersed by sand milling with a sand mill; the dispersed material was microwave-dried using a microwave dryer; the dried material was heat-preserved and calcined at 1180°C for 2.5h, and Ba(Zn 1 / 3 Nb 2 / 3 )O 3 ,spare.

[0060] Take Mg(OH) according to the stoichiometric ratio 2 and TiO 2 Mix the raw materials to obtain a mixture, then add water to the ball mill according to the amount of mixture: water = 1:1.2, and add ammonium acrylate dispersant accounting for 0.5 wt% of the mixture, then add the mixture and mix evenly, ball mill 3h; the ball-milled slurry was dispersed by sand milling with a sand mill; the dispersed mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency temperature coefficient | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com