Dehydroabietyl glycidyl ether grafted water-soluble hydroxypropyl chitosan and preparation method thereof

A technology of hydroxypropyl chitosan and glycidyl ether, which is applied in chemical instruments and methods, dissolution, transportation and packaging, and can solve problems such as poor solubility, limited application, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

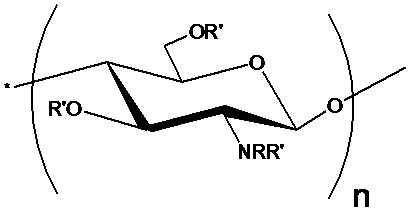

[0029] Such as figure 1 As shown, a dehydroabietyl glycidyl ether grafted water-soluble hydroxypropyl chitosan has the following structure:

[0030]

[0031] The preparation method of dehydroabietyl glycidyl ether grafted water-soluble hydroxypropyl chitosan includes the following steps:

[0032] The first step: according to the mass ratio of sodium hydroxide to chitosan of 1.0~10:1.0, make chitosan alkalized 1.0~48.0 in 10%~50% sodium hydroxide aqueous solution at -20℃~50℃ After hours, disperse the alkalized chitosan in isopropanol according to the mass ratio of chitosan to isopropanol of 1.0:5.0~50.0, and then press the ratio of chitosan and propylene oxide to With a mass ratio of 1.0:0.50~10.0, propylene oxide was added dropwise to the isopropanol in which the alkalized chitosan was dispersed; after the propylene oxide was added, the material was heated in a water bath to increase its temperature to 20~90℃ and Continue to stir the reaction at the corresponding temperature for 1...

Embodiment 2

[0035] The preparation method of dehydroabietyl glycidyl ether grafted water-soluble hydroxypropyl chitosan includes the following steps:

[0036] The first step: according to the mass ratio of sodium hydroxide to chitosan of 1.0~10:1.0, make chitosan alkalized 1.0~48.0 in 10%~50% sodium hydroxide aqueous solution at -20℃~50℃ After hours, disperse the alkalized chitosan in isopropanol according to the mass ratio of chitosan to isopropanol of 1.0:5.0~50.0, and then press the ratio of chitosan and propylene oxide to With a mass ratio of 1.0:0.50~10.0, propylene oxide was added dropwise to the isopropanol in which the alkalized chitosan was dispersed; after the propylene oxide was added, the material was heated in a water bath to increase its temperature to 20~90℃ and Continue to stir the reaction at the corresponding temperature for 1.0-50.0 hours; after the reaction, filter the reaction materials and disperse the resulting filter residue in distilled water, while adding dilute hyd...

Embodiment 3

[0041] The preparation method of dehydroabietyl glycidyl ether grafted water-soluble hydroxypropyl chitosan includes the following steps:

[0042] The first step: according to the mass ratio of sodium hydroxide to chitosan of 1.0~10:1.0, make chitosan alkalized 1.0~48.0 in 10%~50% sodium hydroxide aqueous solution at -20℃~50℃ After hours, disperse the alkalized chitosan in isopropanol according to the mass ratio of chitosan to isopropanol of 1.0:5.0~50.0, and then press the ratio of chitosan and propylene oxide to With a mass ratio of 1.0:0.50~10.0, propylene oxide was added dropwise to the isopropanol in which the alkalized chitosan was dispersed; after the propylene oxide was added, the material was heated in a water bath to increase its temperature to 20~90℃ and Continue to stir the reaction at the corresponding temperature for 1.0-50.0 hours; after the reaction, filter the reaction materials and disperse the resulting filter residue in distilled water, while adding dilute hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com