Polymer capable of quickly adsorbing low-concentration formaldehyde, and preparation method thereof

A low-concentration, polymer-based technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low adsorption capacity and limitation of adsorption capacity, and achieve large specific surface area, low production cost and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

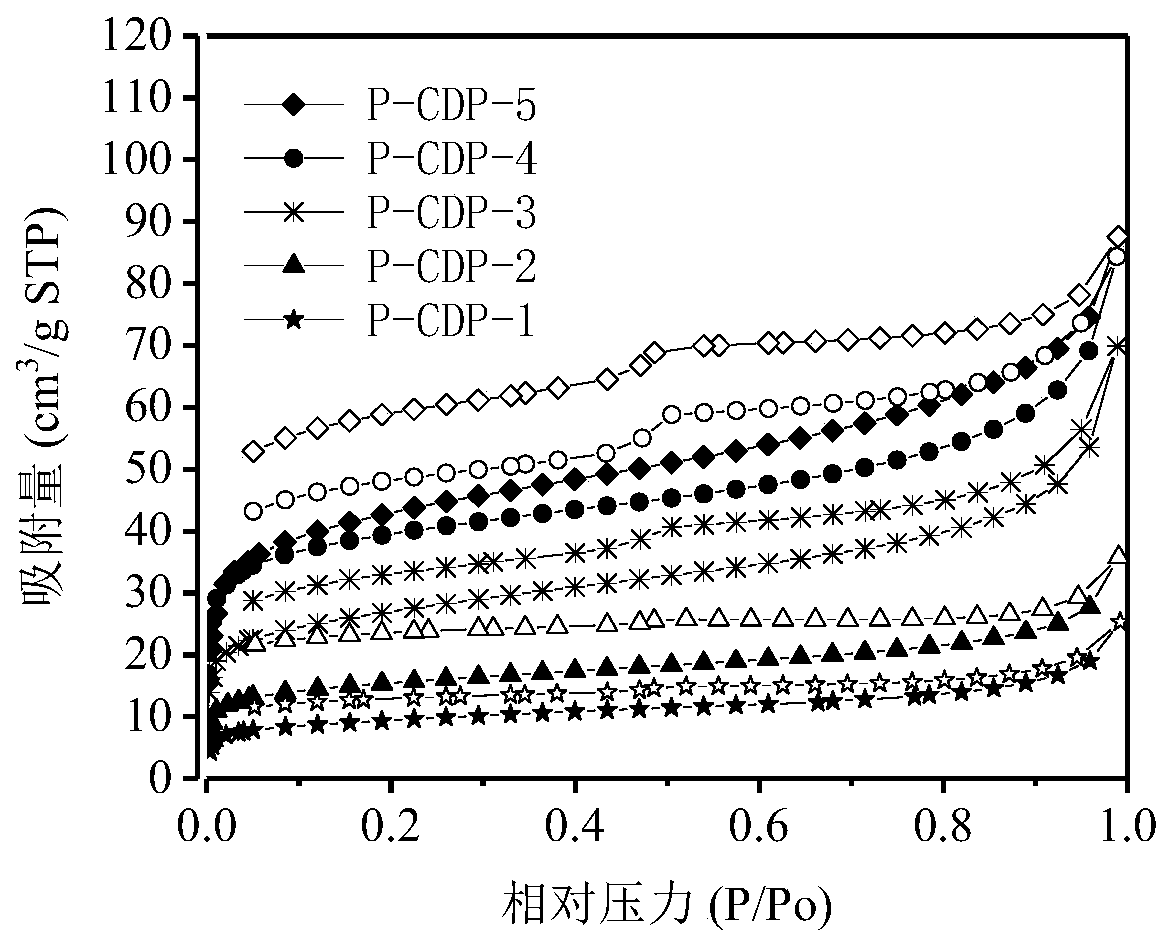

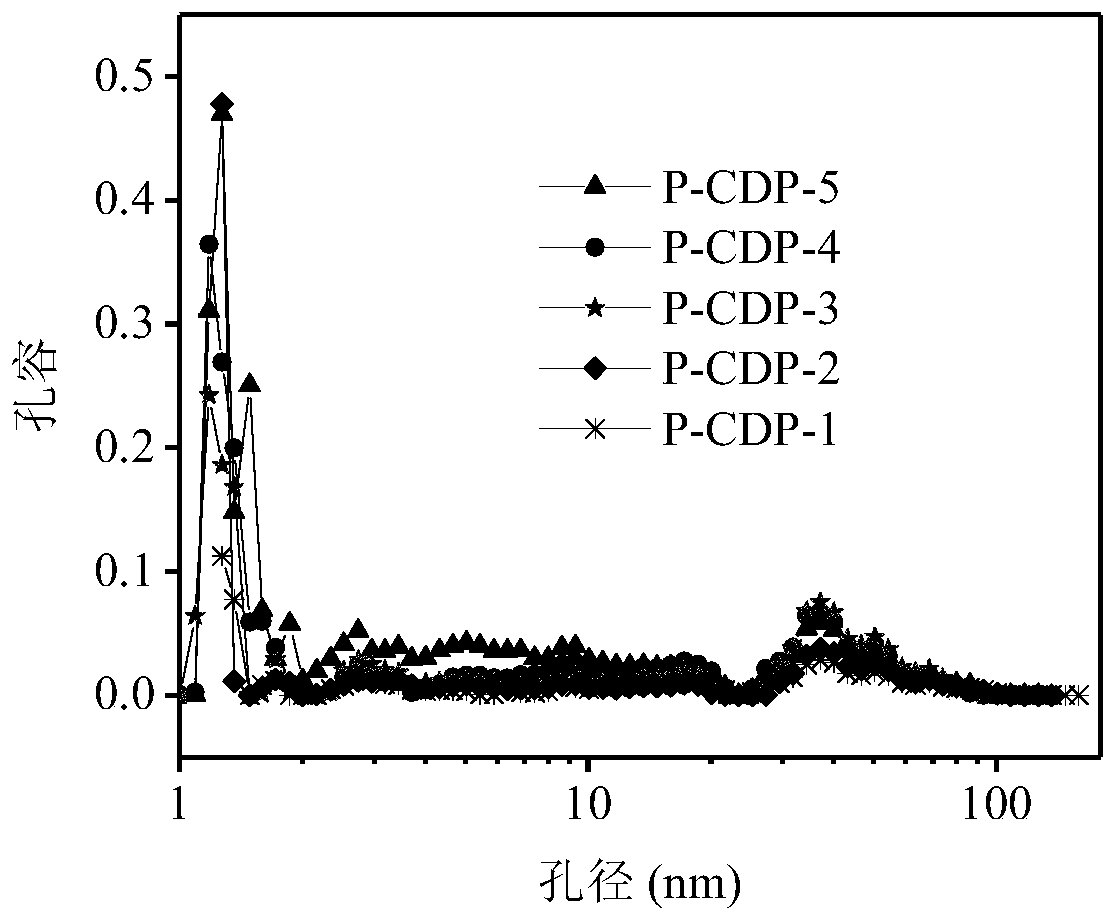

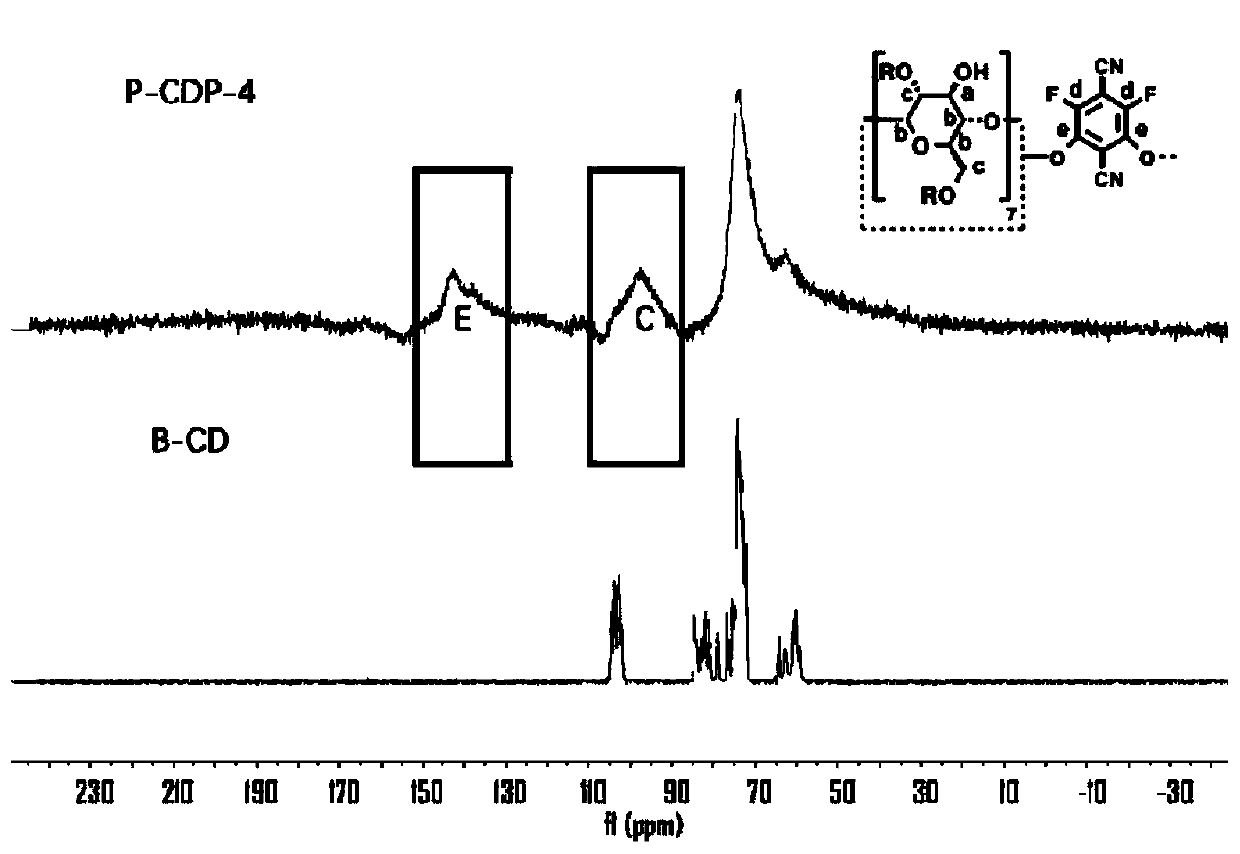

Embodiment 1

[0039] (1) 0.600g of β-cyclodextrin and 0.200g of tetrachloroterephthalonitrile and 0.900g of potassium carbonate were dissolved in 16ml of solvent (H 2 O: the volume ratio of DMF is 10:1), obtains mixed solution;

[0040] (2) Sonicate the mixed solution obtained in step (1) for 1 min, purging the solution with nitrogen for 60 min, put the mixed solution into a microwave reactor, heat and stir the reaction at 60 ° C with 50 W power for 20 h, and the porous β-cyclodextrin polymer;

[0041] (3) Wash the porous β-cyclodextrin polymer with hydrochloric acid until no bubbles are generated, filter it, soak it in water and dichloromethane for 24 hours to activate it, and dry it in vacuum at 55°C to obtain the activated porous β-cyclodextrin polymer , denoted as P-CDP-1.

Embodiment 2

[0043] (1) 0.600g of β-cyclodextrin and 0.300g of tetrachloroterephthalonitrile and 0.900g of potassium carbonate were dissolved in 16ml of solvent (H 2 O: the volume ratio of DMF is 10:1), obtains mixed solution;

[0044] (2) Sonicate the mixed solution obtained in step (1) for 30 minutes, purging the solution with nitrogen for 1 minute, put the mixed solution in a microwave reactor, heat and stir at 120°C for 3 hours with 30W power, and the porous β-cyclodextrin polymer;

[0045] (3) Wash the porous β-cyclodextrin polymer with hydrochloric acid until no bubbles are generated, filter and soak in water and dichloromethane for 48 hours to activate, and vacuum-dry at 90°C to obtain the activated porous β-cyclodextrin polymer , denoted as P-CDP-2.

Embodiment 3

[0047] (1) Dissolve 0.600g of β-cyclodextrin, 0.400g of tetrafluoroisophthalonitrile and 0.900g of potassium carbonate in 16ml of solvent (the volume ratio of tetrahydrofuran:DMF is 9:1) to obtain a mixed solution ;

[0048] (2) Sonicate the mixed solution obtained in step (1) for 15 minutes, purging the solution with nitrogen for 30 minutes, put the mixed solution in a microwave reactor, heat and stir at 90°C for 12 hours with a power of 75W, and the porous β-cyclodextrin polymer;

[0049] (3) Wash the porous β-cyclodextrin polymer with hydrochloric acid until no bubbles are generated, filter and soak in water and dichloromethane for 10 minutes to activate, and dry in vacuum at 30°C to obtain the activated porous β-cyclodextrin polymer , denoted as P-CDP-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com