High-temperature-resistant environment-friendly plastic particle and preparation method thereof

An environmentally friendly plastic and high-temperature-resistant technology, applied in the field of plastic production, can solve the problems of short duration, small antibacterial range, and failure to meet long-term and spectral antibacterial requirements, and achieve long antibacterial time, good environmental performance, excellent weather resistance and The effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

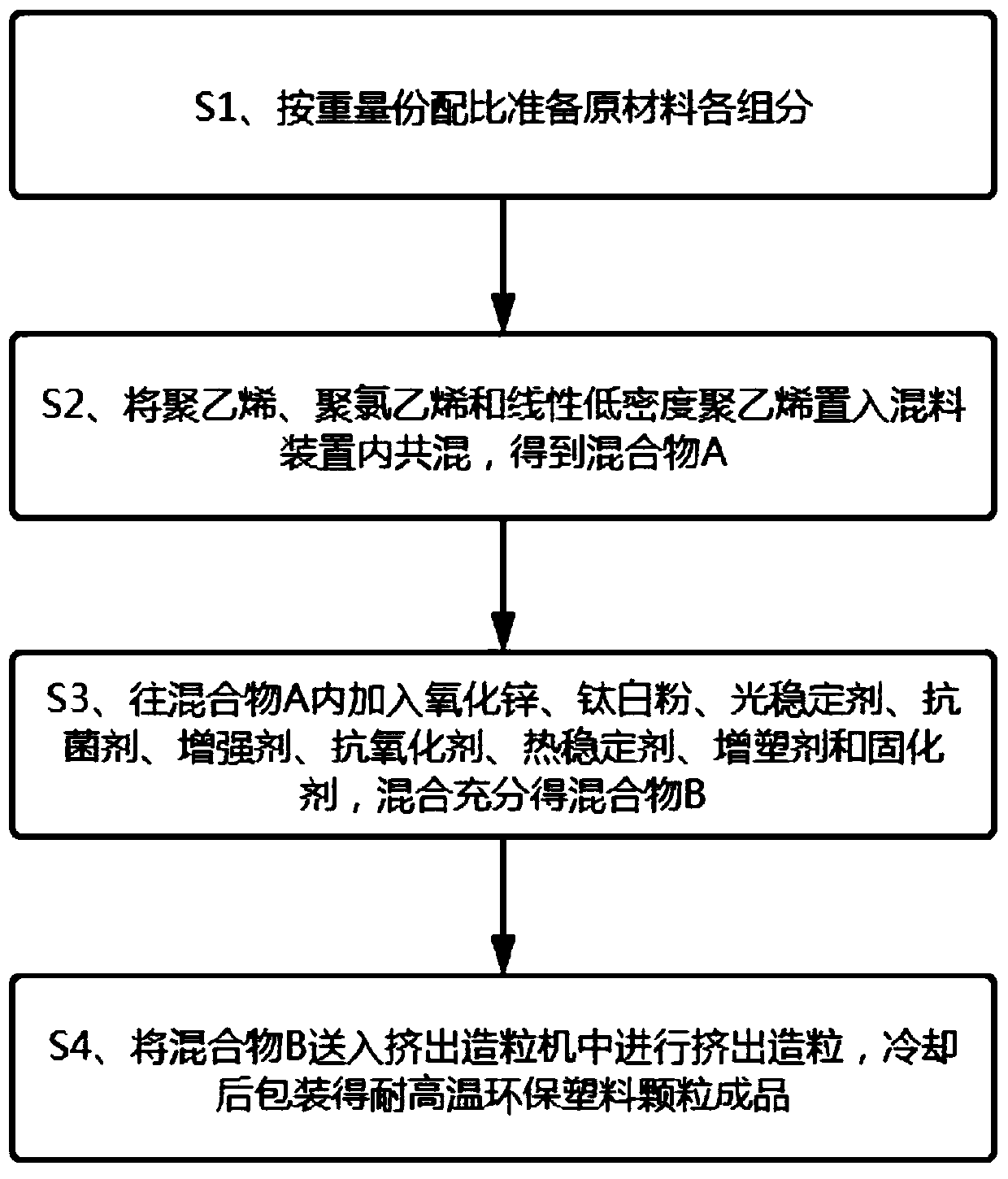

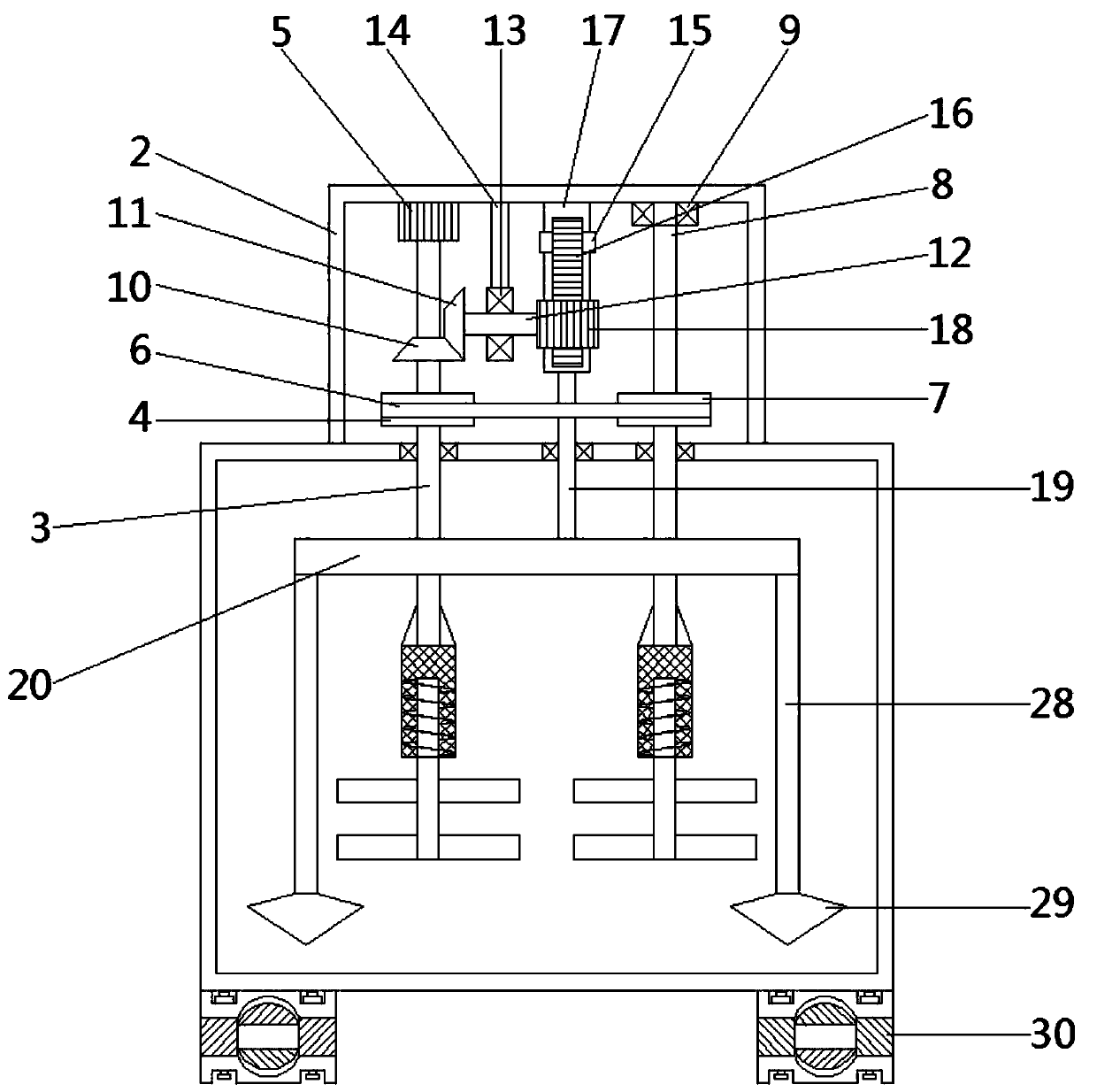

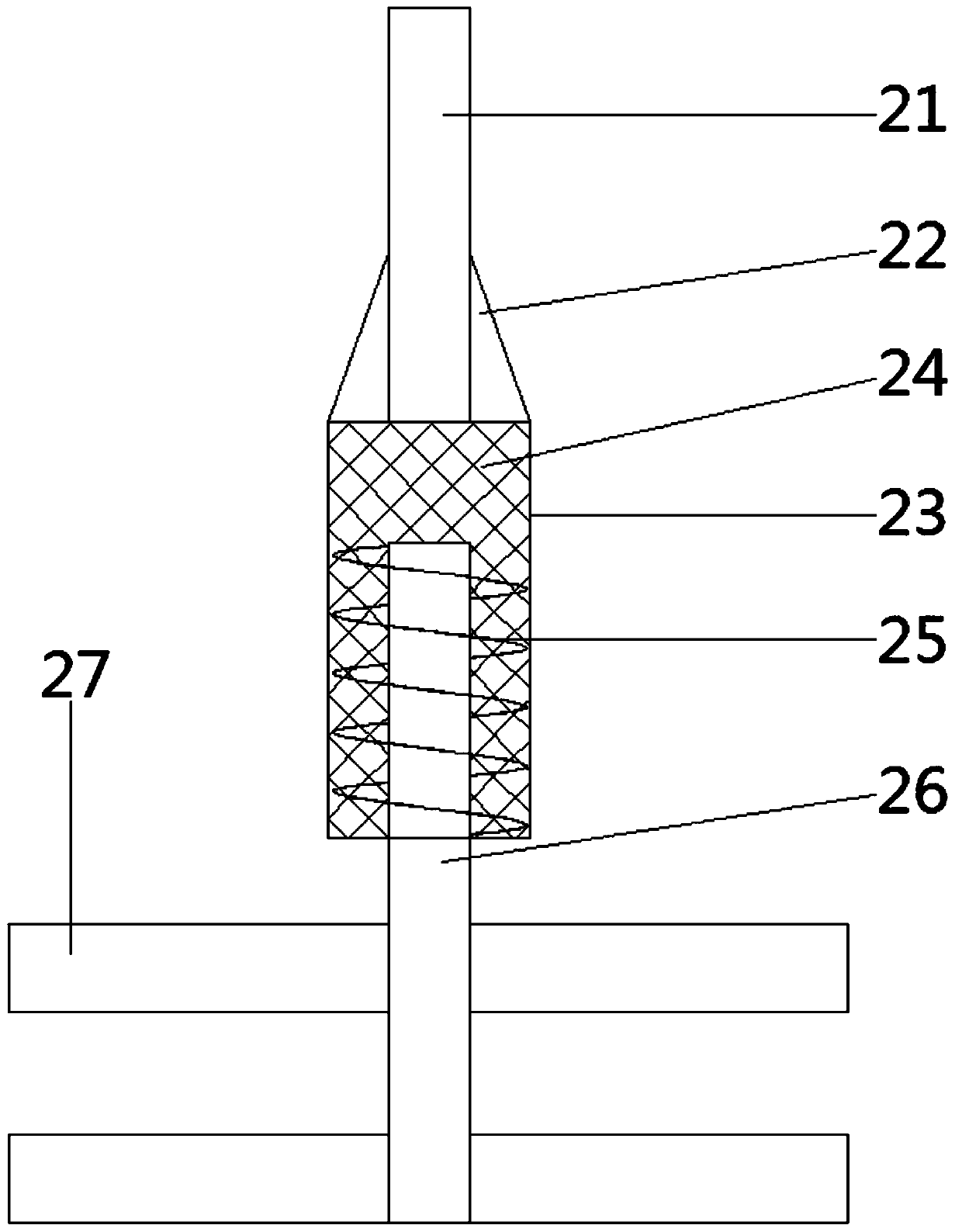

Method used

Image

Examples

Embodiment 1

[0039] A kind of high-temperature-resistant environment-friendly plastic granules, comprising the following components by weight:

[0040] 40-50 parts of polyethylene, 30-40 parts of polyvinyl chloride, 10-20 parts of linear low-density polyethylene, 3-5 parts of zinc oxide, 8-10 parts of titanium dioxide, 2-4 parts of light stabilizer, 2 parts of antibacterial agent -4 parts, 3-5 parts of reinforcing agent, 3-5 parts of antioxidant, 4-5 parts of heat stabilizer, 3-5 parts of plasticizer, 3-5 parts of curing agent.

[0041] Titanium dioxide includes rutile titanium dioxide and anatase titanium dioxide, the light stabilizer is nano-titanium dioxide, and the antibacterial agent is nano-silver.

[0042] The reinforcing agent is mica, and the antioxidant is naphthylamine, diphenylamine, p-phenylenediamine, hydroquinone or thiobisphenol.

[0043] The heat stabilizer is a mixture of barium alkylphenol, cadmium laurate, and zinc naphthenate, the plasticizer is phthalate, and the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com