High-CTI flame-retardant polycarbonate alloy material, preparation method and applications thereof

A technology for flame-retardant polycarbonate and alloy materials, which is applied in the fields of polymer molding and polymer blending, and can solve the problems of limited use and low heat resistance of alloy materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

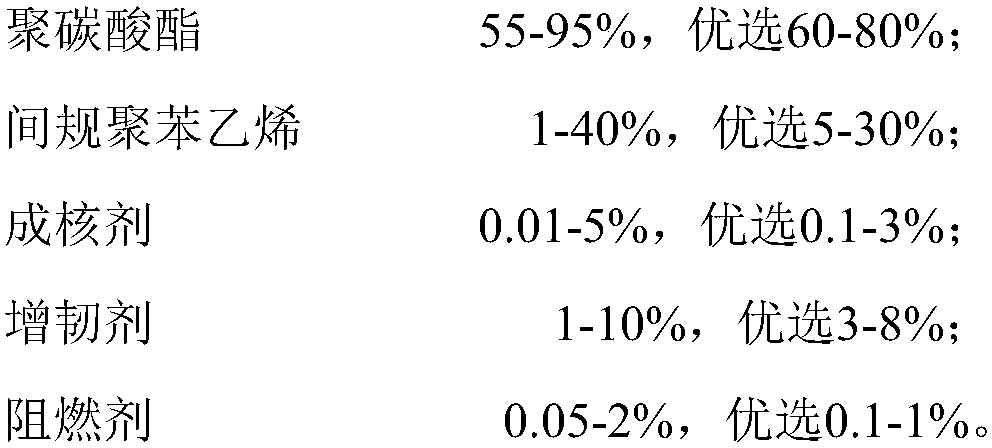

Method used

Image

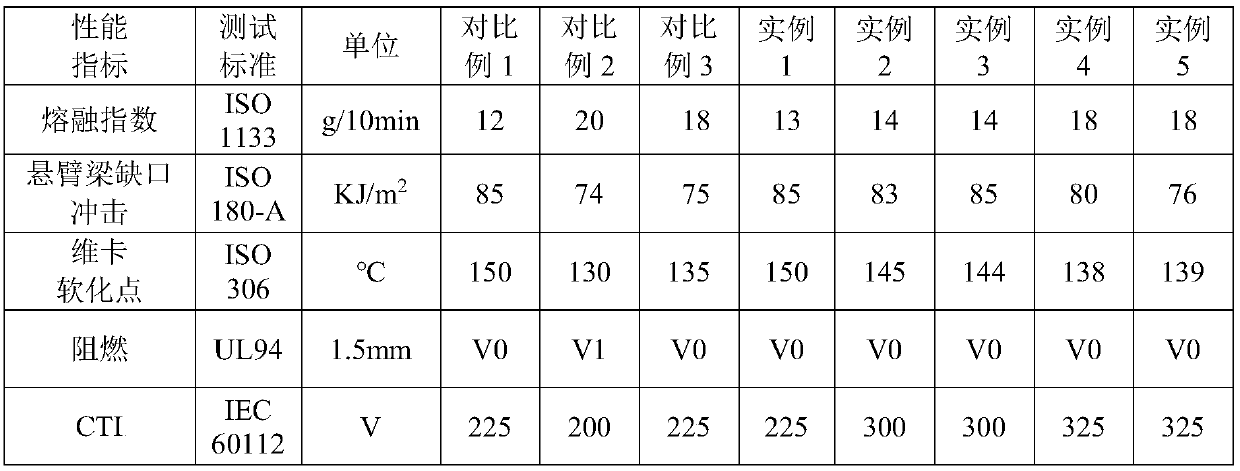

Examples

Embodiment 1

[0044] (1) Weigh 9.5kg for A1105, 0.1kg for S100, 0.04kg for nano-calcium carbonate, 0.04kg for X-52-875, 0.02kg for FR2025, 0.3kg for SMA2021, 0.03g for SN3300B3, and 0.02kg, PETS is 0.03kg;

[0045](2) Mix the weighed material in the high mixer for 5 minutes before discharging;

[0046] (3) Put the material into the twin-screw extruder, and set the temperature of each section of the extruder as follows (from the feeding port to the machine head): 80°C, 270°C, 320°C, 320°C, 320°C, 320°C, 320°C, 320°C, 310°C, 310°C. The die temperature is 310°C, the extrusion speed is 100RPM, and the modified material is water-cooled and granulated after being extruded from the die.

Embodiment 2

[0048] (1) Weigh 9kg for A1105, 0.5kg for S100, 0.072kg for nano-calcium carbonate, 0.008kg for X-52-875, 0.02kg for FR2025, 0.4kg for SMA2021, 0.03g for SN3300B3, and 0.02kg for antioxidant kg, PETS is 0.03kg;

[0049] (2) Mix the weighed material in the high mixer for 5 minutes before discharging;

[0050] (3) Put the material into the twin-screw extruder, and set the temperature of each section of the extruder as follows (from the feeding port to the machine head): 80°C, 270°C, 300°C, 300°C, 300°C, 300°C, 300°C, 300°C, 290°C, 290°C. The temperature of the die is 290°C, the extrusion speed is 300RPM, and the modified material is extruded from the die and granulated by water cooling.

Embodiment 3

[0052] (1) Weigh 9kg for A1105, 0.5kg for S100, 0.005kg for nano calcium carbonate, 0.005kg for X-52-875, 0.02kg for FR2025, 0.47kg for SMA2021, 0.03g for SN3300B3, and 0.02kg for antioxidant kg, PETS is 0.03kg;

[0053] (2) Mix the weighed material in the high mixer for 5 minutes before discharging;

[0054] (3) Put the material into the twin-screw extruder, and set the temperature of each section of the extruder as follows (from the feeding port to the machine head): 80°C, 270°C, 300°C, 300°C, 300°C, 300°C, 300°C, 300°C, 290°C, 290°C. The temperature of the die is 290°C, the extrusion speed is 300RPM, and the modified material is extruded from the die and granulated by water cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com