Flexible electrode material and its preparation method and flexible supercapacitor

A technology of supercapacitors and flexible electrodes, applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of low mechanical strength, poor stability and repeatability of electrode materials, and many control variables, and achieve high specific surface area. , Good penetration, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

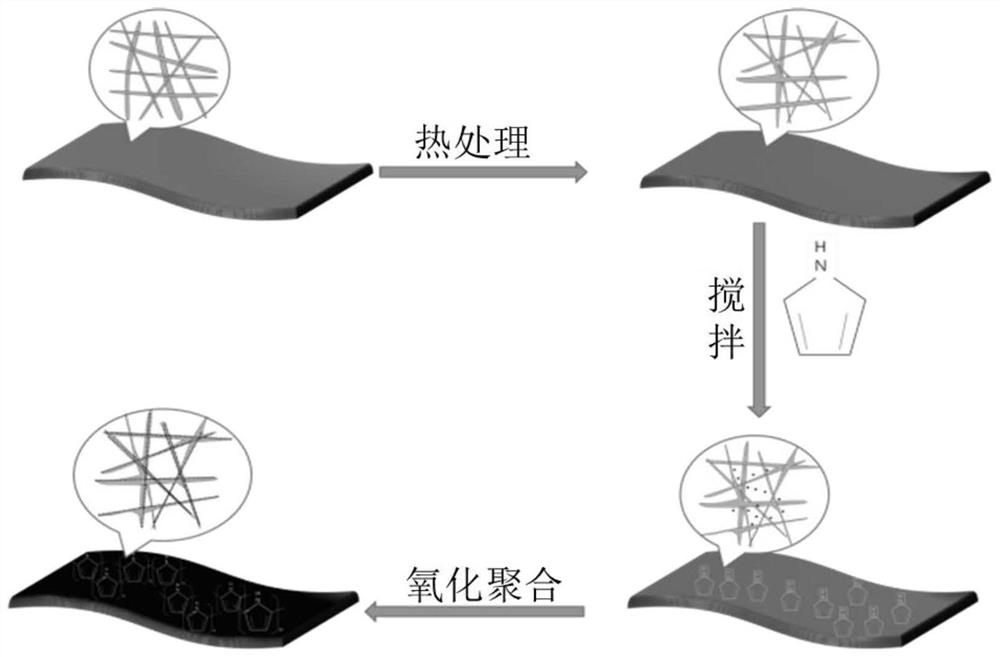

[0047] see Figure 1 to Figure 3 As shown, a flexible electrode material is prepared by the following method:

[0048] S1. Preparation of electrospinning solution: dissolve nylon 6 masterbatch in formic acid, and stir in a water bath heated at a constant temperature of 40°C to obtain a nylon 6 spinning solution with a mass concentration of 15%; The amide masterbatch is dissolved in a mixed solvent of formic acid and dichloromethane with a volume ratio of 3:2, and stirred in a water bath heated at a constant temperature of 40°C to obtain a copolyamide spinning solution with a mass concentration of 10%;

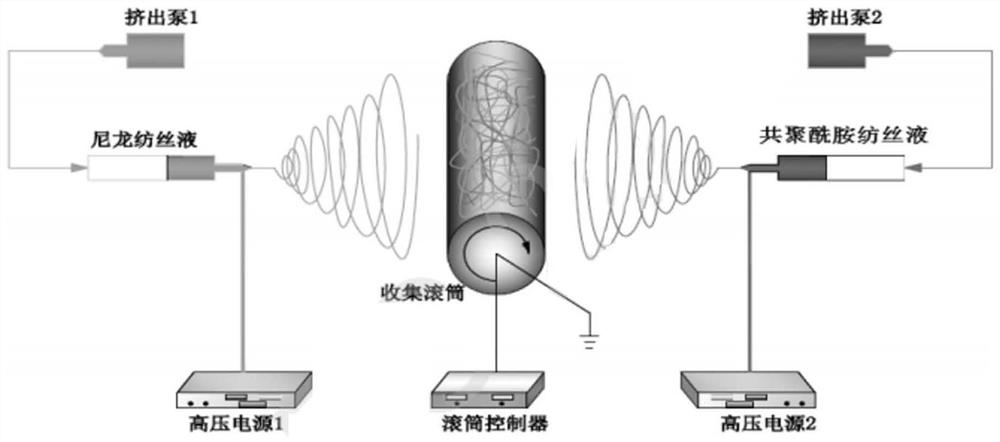

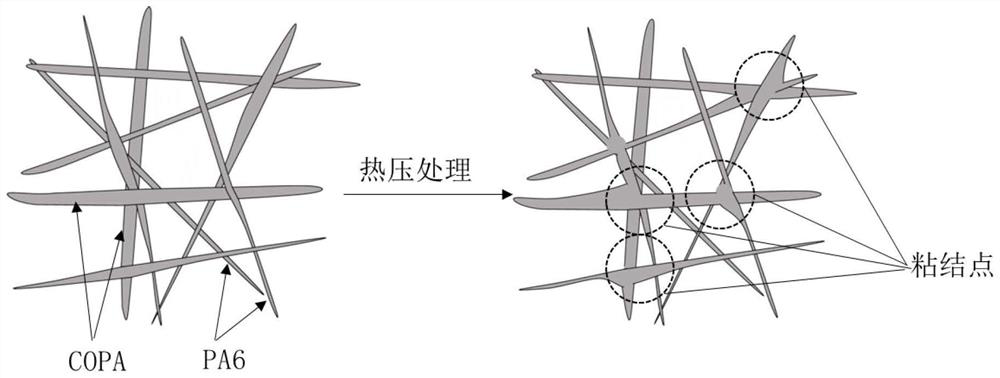

[0049] S2. Electrospinning: put the nylon 6 spinning solution and the copolyamide spinning solution into two different syringes respectively, use No. 22 nozzle as the nozzle, place the syringe in the pump and fix it for synchronous electrospinning, The spinning voltage is 20kv, the spinning distance is 20cm, and the extrusion speed is 0.015mm / min. The electrostatic nanofiber f...

Embodiment 2~6

[0060] The flexible electrode materials provided in Examples 2-6 are different from those in Example 1 in that the hot-pressing temperature is shown in Table 1, and the others are basically the same as those in Example 1, and will not be repeated here.

Embodiment 7~10 and comparative example 3

[0069] The flexible electrode materials provided in Examples 7 to 10 and Comparative Example 3, compared with Example 1, differ in that the concentrations of the copolyamide spinning solution and the nylon 6 spinning solution are as shown in Table 2, and the others are the same as those in Example 1. 1 are basically the same and will not be repeated here.

[0070] Preparation conditions and performance test results of Table 2 Examples 7-10 and Comparative Example 3

[0071]

[0072] It can be seen from Table 2 that with the increase of the concentration of the copolyamide spinning solution, the tensile strength and electrical conductivity of the nanofiber-based flexible electrode material first increase and then decrease. combine Image 6 It can be seen that when the concentration of the copolyamide spinning solution is too high, the diameter of the copolyamide becomes larger, and it is in a flat ribbon shape. After heat treatment, it is prone to adhesion and the specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com