Online monitoring equipment and monitoring method for perovskite solar cell production process

A solar cell and production process technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of thin film uniformity, poor repeatability, affecting battery efficiency, and repeatability to be improved, and achieve the effect of improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

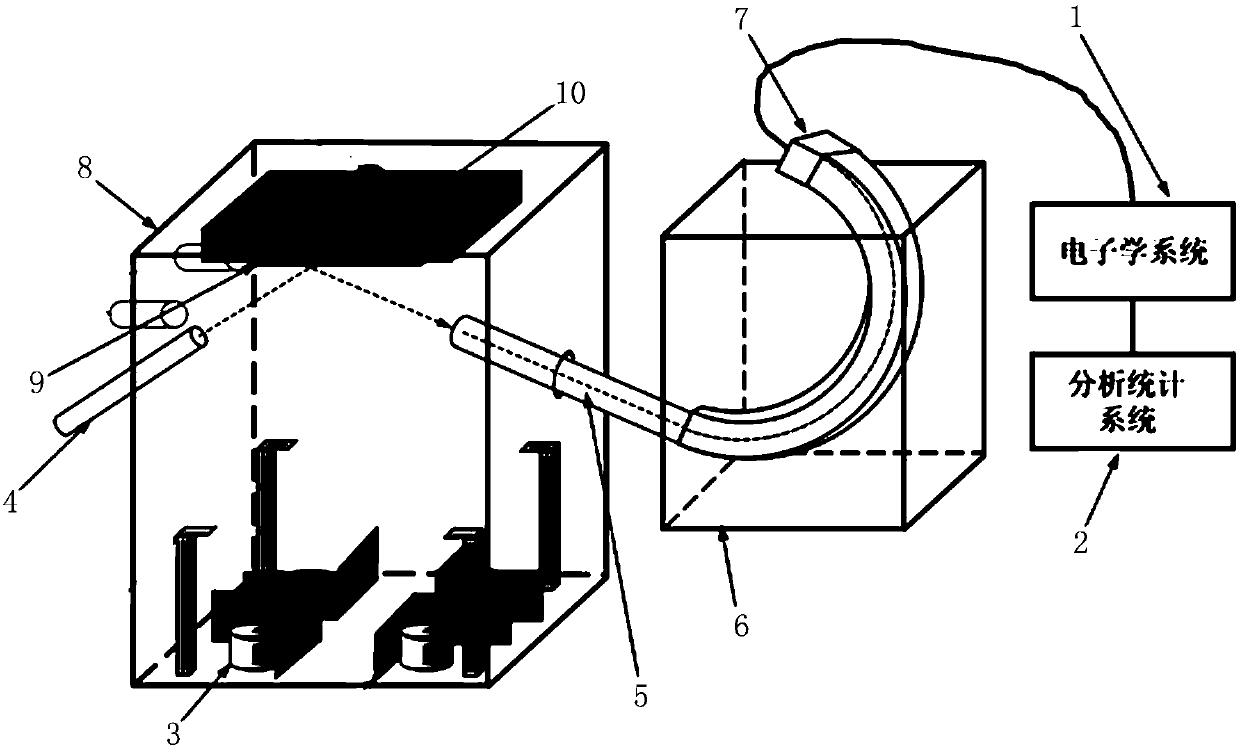

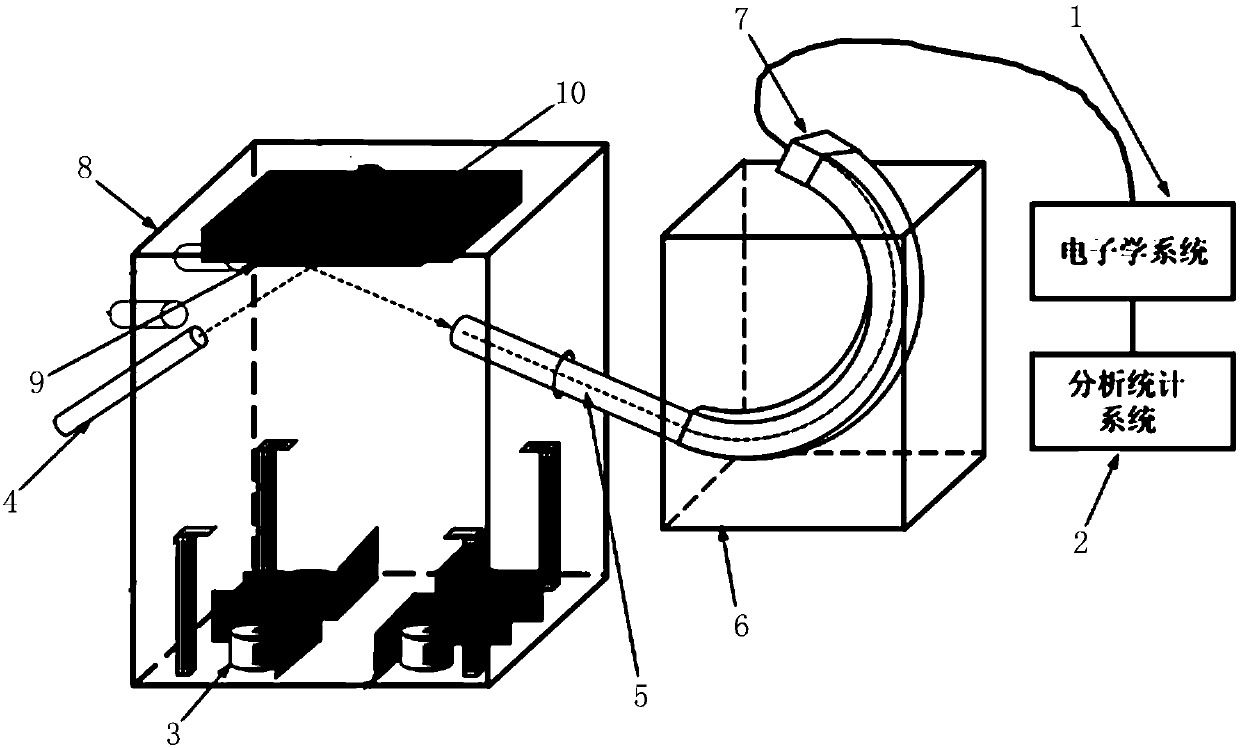

Method used

Image

Examples

specific Embodiment

[0027] (1) Clean a 5×5cm ITO glass plate with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes.

[0028] (2) Scrape-coat PEDOT:PSS aqueous solution on the above ITO glass to prepare a hole transport layer.

[0029] (3) Preparation of metal halide thin film precursor solution: Dissolve 461mg of PbI2 in 1mL of DMF solution (1mmol), heat and stir at 60°C for 2h, dissolve and set aside.

[0030] (4) Preparation of PbI by slot coating using prepared precursor solution 2 film.

[0031] (5) Place the prepared metal halide film in a vacuum evaporation chamber, and use a vacuum pump to control the air pressure at 10 -5 Pa~10 5 Pa, the evaporation source is methylammonium iodide (MAI). 2 Thin film reaction generates perovskite thin film MAPbI 3 .

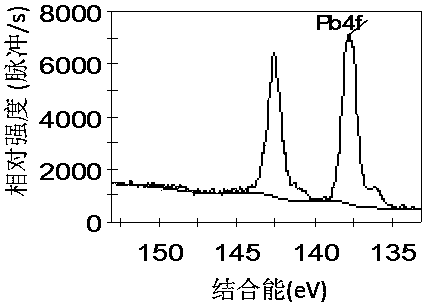

[0032] (6) During the above reaction process, the surface of the perovskite solar cell substrate is irradiated with X-rays once per minute,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com