Machining method of high-precision superhard-abrasive integral abrasive cutting wheel

A technology for cutting grinding wheels and super-hard abrasives, applied in abrasives, bonded grinding wheels, metal processing equipment, etc., can solve problems such as low efficiency, low yield, operating conditions and environmental pollution, and reduce deformation and damage. The effect of improving and improving the processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

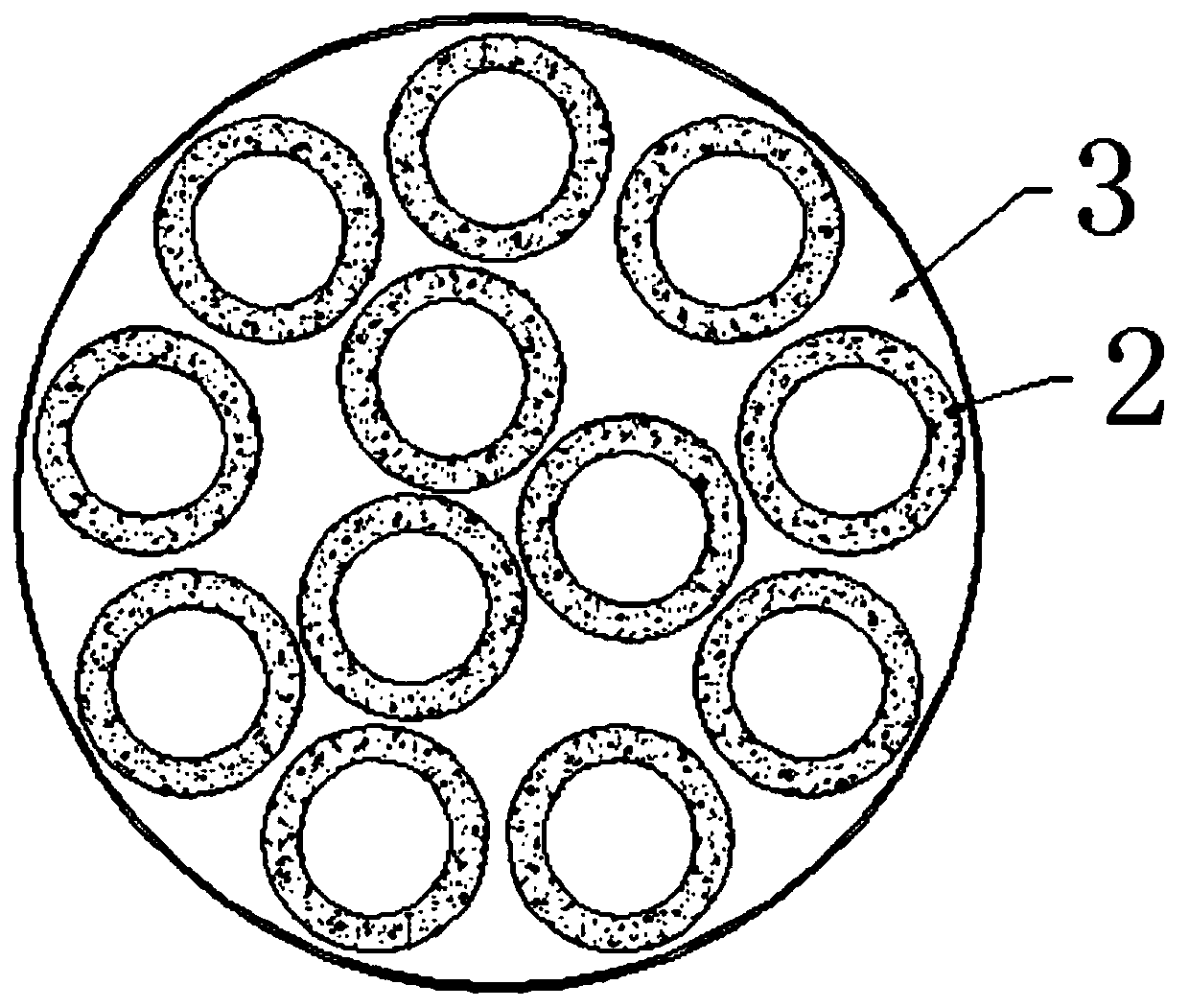

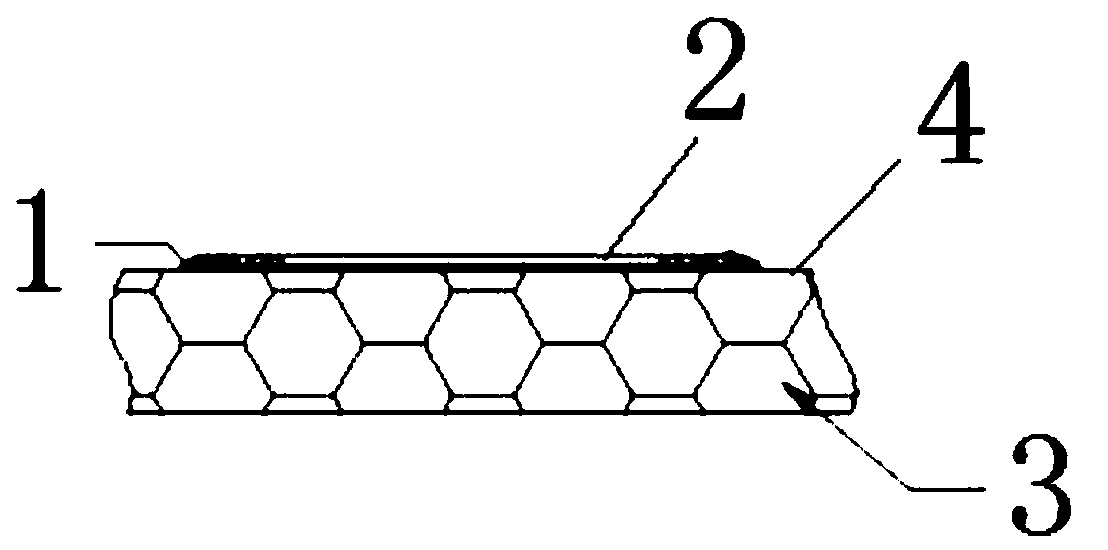

[0052] Manufacture of cutting wheels with a thickness of 0.3mm, which are made of metal bond and diamond sintered blanks

[0053] A. Use a blank with a thickness of 0.35mm, and the parallelism of the two surfaces of the blank AB is 0.02mm; use a ratio measuring platform and a dial gauge to measure the original thickness and parallelism accuracy of the blank one by one, and make a good mark and record;

[0054] Rosin is used as a thermoplastic material, and alumina ceramic is used as a fixed carrier. It is ground by a precision CNC horizontal axis round table surface grinder; the grinding wheel is 180 mesh green silicon carbide, its width is 6mm, and its hardness is L-level;

[0055] B. Heat the alumina ceramic carrier on the heating platform at a heating temperature of 150-200°C. Coat the hot thermoplastic material rosin on the carrier, put the B surface of the blank on the coated rosin and connect with the carrier, and let it stand for 2 minutes. Move the carrier as a whole to the p...

Embodiment 2

[0062] Processing and manufacturing 0.3mm cutting wheels. The cutting wheel material is ceramic bond and diamond sintered blank;

[0063] A. A blank with a thickness of 0.35mm is used, and the parallelism of the AB sides is 0.03mm.

[0064] Solid wax is used as a thermoplastic material, and silicon carbide ceramic is used as a fixed carrier: a vertical precision round-table grinding machine is used for grinding; the grinding wheel is made of 240 mesh single crystal corundum, the hardness is G level, and the structure is a 4mm single ring grinding wheel;

[0065] B. Heat the silicon carbide ceramic carrier through the heating platform at a heating temperature of 90-140°C, apply the solid wax to the carrier, and place the blank on the coated solid wax. The surface B is used as the fixed surface and let it stand for 2 minutes. Move the carrier as a whole to the pressurizing device, apply 400kgf to the carrier, fixing material, and cutting wheel blank as a whole, and cool to room temper...

Embodiment 3

[0071] Manufacturing a cutting wheel with a thickness of 0.05mm, the cutting wheel is made of metal bond and diamond sintered blank

[0072] Using a blank with a thickness of 0.1mm, the parallelism of the two sides of the blank AB is 0.03mm;

[0073] Thermoplastic adhesive such as JY-1 is used as a thermoplastic material, and zirconia ceramic is used as a fixed carrier: horizontal precision grinding machine is used for grinding; the grinding wheel particle size is 240 mesh, the hardness of green silicon carbide is K grade, and its width is 12mm single ring structure Grinding wheel,;

[0074] The heating temperature of the carrier is 90-140℃, the linear speed of the grinding wheel is 10m / s, the feed speed is 0.3um / s, and the grinding wheel feed is 0.2mm;

[0075] When the two sides are alternately processed, the feed speed is 0.1um / s, and the grinding wheel feed is 0.05mm;

[0076] The cutting wheel with a thickness of 0.05mm obtained by the above method has a thickness uniformity of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com