Device for producing fuel ethanol by furfural residue forced circulation high-solid gas stripping fermentation

A forced circulation, fuel ethanol technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biological material sampling methods, etc., can solve problems such as yeast poisoning, increase utilization, enhance yeast cell activity, Toxic reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

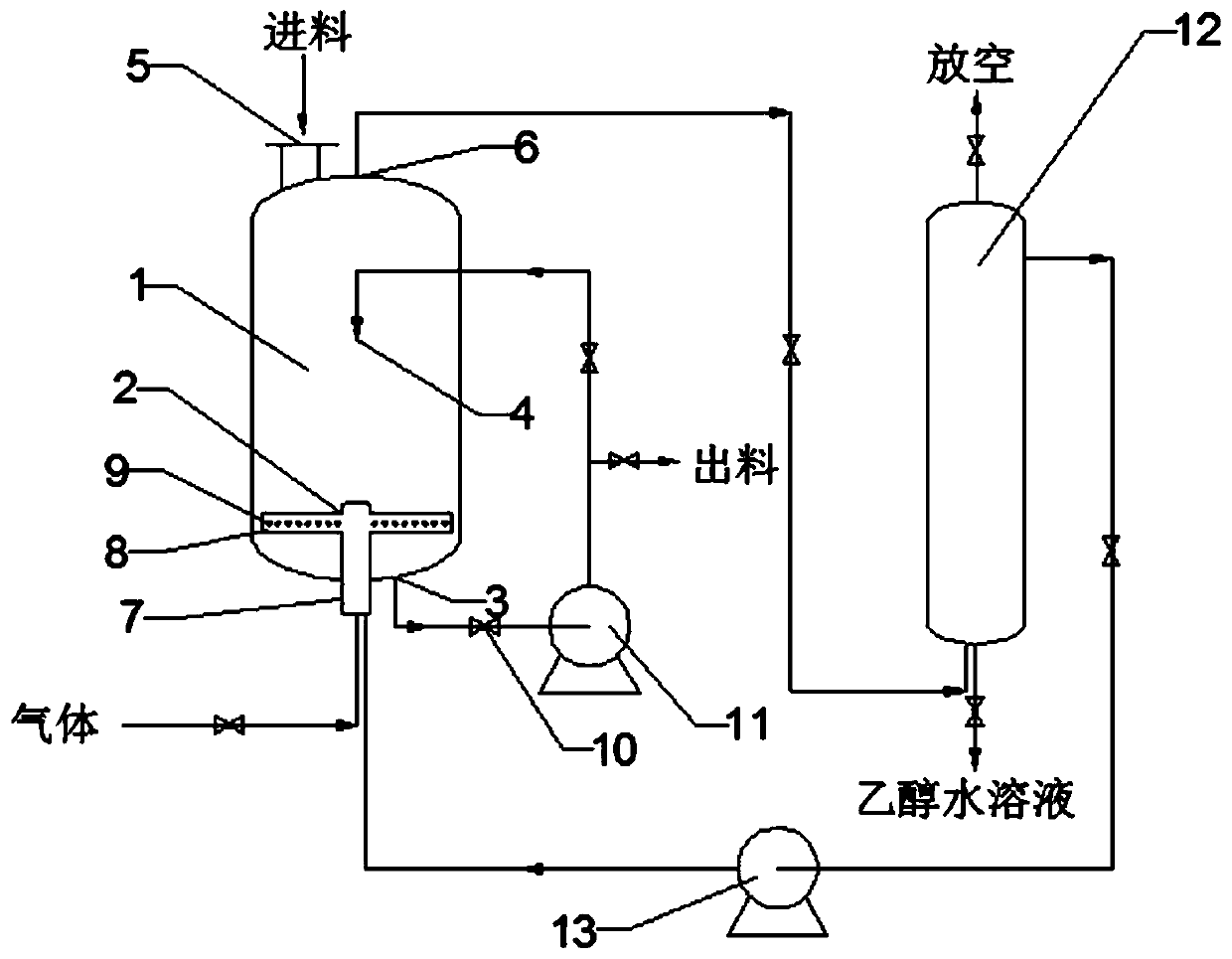

[0025] The washed furfural residue, cellulase and Saccharomyces cerevisiae dry powder are fed into the forced circulation air-lift fermenter (1) through the feed port (5), the total solid content is 50%, and the amount of cellulase added is 30 FPU / g (based on glucan content), the addition amount of Saccharomyces cerevisiae dry powder is 1 g / L, the temperature of enzymolysis and fermentation is controlled at 35°C, and the pH is 5.0. The furfural slag material is connected to the discharge valve (10) through the feed liquid outlet (3), forced to circulate through the discharge pump (11) and sprayed into the fermentation tank through the inlet (4) to realize the forced circulation of the furfural slag fermentation material;

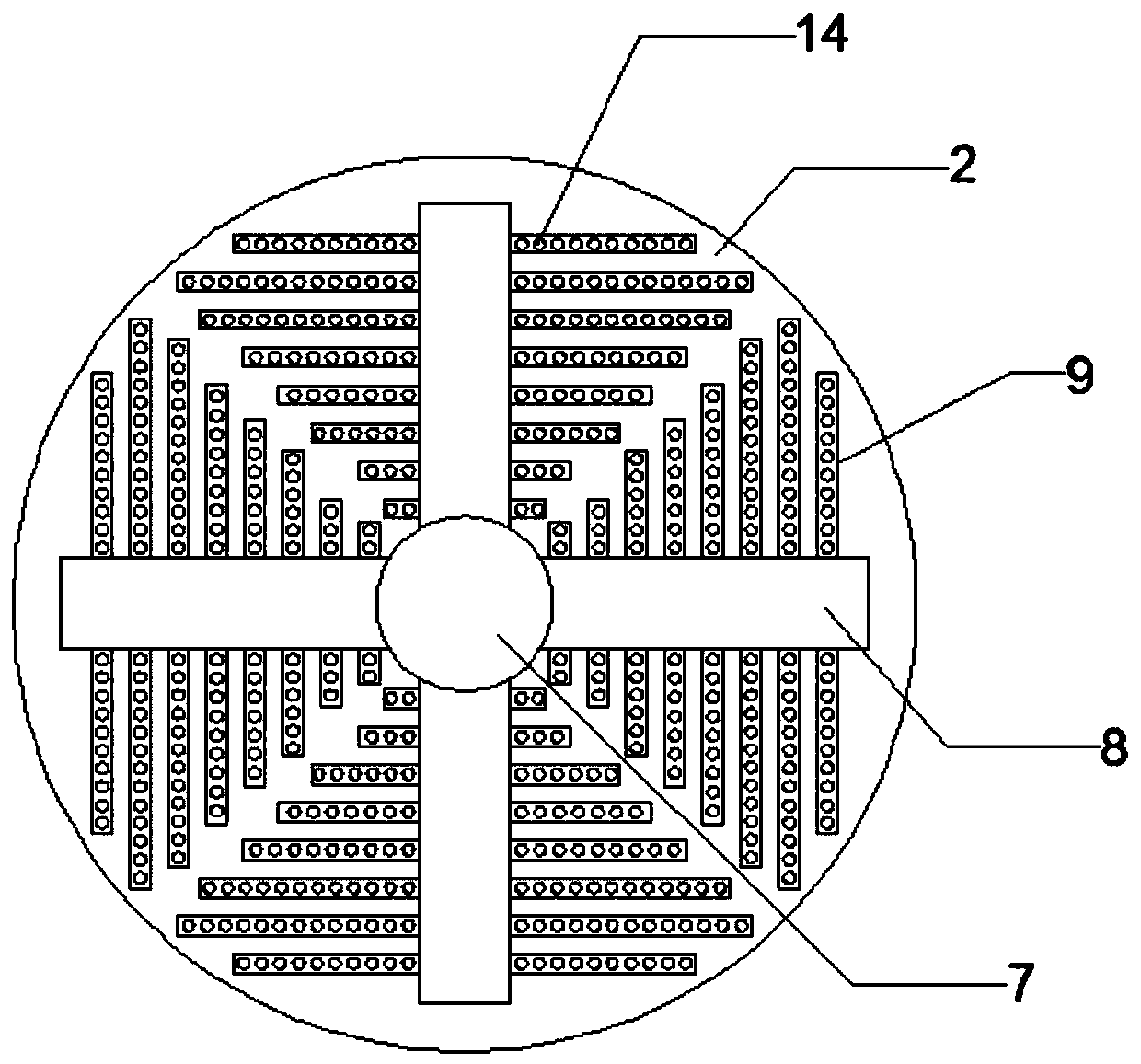

[0026] The air enters the distribution pipes (8) through the main air intake pipe (7), and enters the fermentation tank through the air intake holes (14) on the upper part of each branch pipe (9). After 24 hours, the air is stopped and the carbon dioxide ga...

Embodiment 2

[0028] The furfural slag, cellulase and Saccharomyces cerevisiae seed liquid after alkaline pretreatment are sent into the forced circulation air-lift fermenter (1) through the feed port (5), the total solid content is 55%, and the addition of cellulase The amount is 35 FPU / g (based on glucan content), the addition amount of Saccharomyces cerevisiae seed solution is 10%, the temperature of enzymolysis and fermentation is controlled at 38°C, and the pH is 5.5. The furfural slag material is connected to the discharge valve (10) through the feed liquid outlet (3), forced to circulate through the discharge pump (11) and sprayed into the fermentation tank through the inlet (4) to realize the forced circulation of the furfural slag fermentation material;

[0029] The air enters the distribution pipes (8) through the main air intake pipe (7), and enters the fermentation tank through the air intake holes (14) on the upper part of each branch pipe (9). After 12 hours, the air is stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com