Improved tailings soil matrix and preparation method thereof

A soil and substrate technology, applied in planting substrates, botanical equipment and methods, culture medium, etc., can solve problems such as affecting the growth of crops, and achieve the effects of simple methods, improved soil structure, and increased nitrogen fixation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

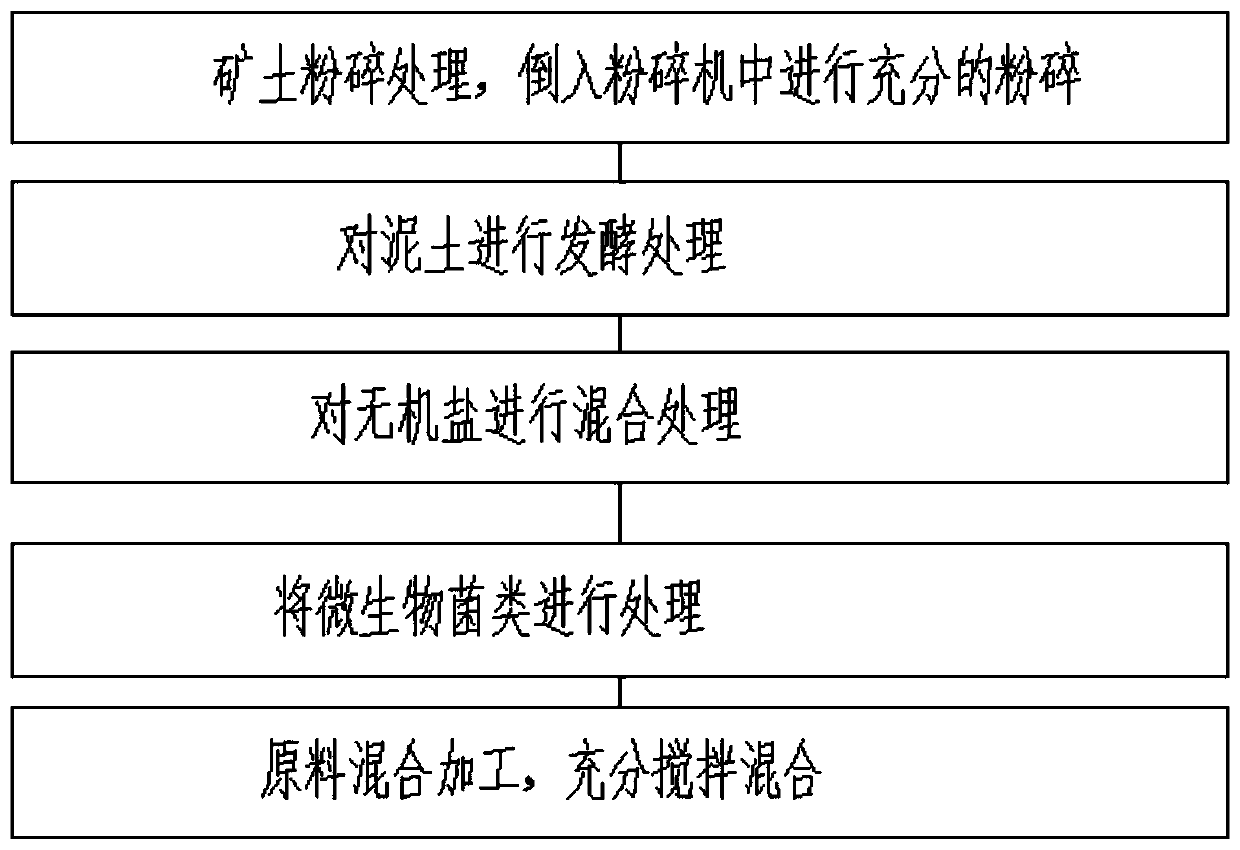

Method used

Image

Examples

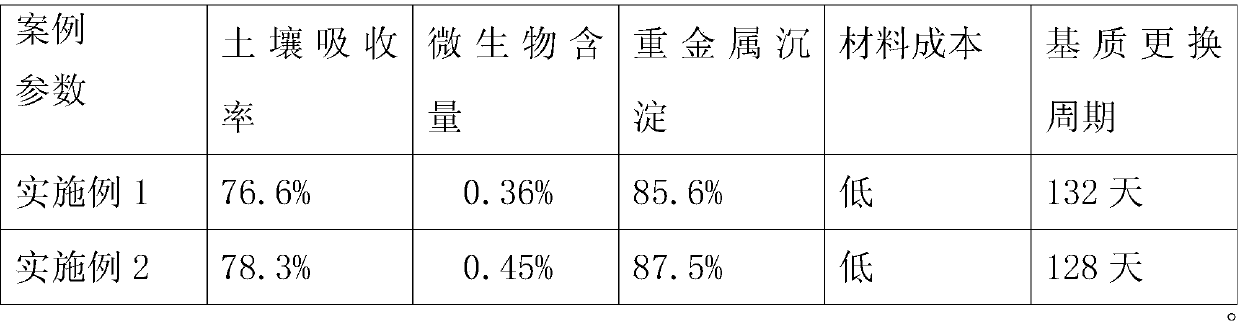

Embodiment 1

[0037] 6 parts of granite, 6 parts of basalt, 8 parts of quartzite, 6 parts of shale, 4 parts of red sandstone, 6.5 parts of river mud, 5 parts of turf soil, 3 parts of swamp soil, 6 parts of pine needle soil, 6 parts of humus soil, peat 7 parts, 4 parts of acetic acid, 8 parts of copper nitrate, 1.8 parts of iron nitrate, 1.5 parts of calcium nitrate, 1.2 parts of calcium phosphate, 2 parts of magnesium phosphate, 4 parts of sodium phosphate, 5.5 parts of mycorrhizal fungi, 3 parts of Streptomyces jingyang, coagulation 4 parts of Bacillus, 2 parts of Paecilomyces lilacinus.

[0038] First crush the ore soil, first pour granite, basalt, quartzite, such as shale, red sandstone into the crusher for sufficient crushing;

[0039] Then ferment the soil, seal and mix river mud, turf soil, swamp soil, pine needle soil, humus soil, peat, and acetic acid, then inject nitrogen, and then add sucrose solution with a concentration of 65 to mix, treat at room temperature, and control the time...

Embodiment 2

[0045] 3.5 parts of granite, 3 parts of basalt, 4 parts of quartzite, 2 parts of shale, 1.8 parts of red sandstone, 4 parts of river mud, 2 parts of turf soil, 1 part of swamp soil, 2 parts of pine needle soil, 3.5 parts of humus soil, peat 4 parts, 1.5 parts of acetic acid, 3 parts of copper nitrate, 0.8 parts of iron nitrate, 0.6 parts of calcium nitrate, 0.5 parts of calcium phosphate, 1 part of magnesium phosphate, 2 parts of sodium phosphate, 4.5 parts of mycorrhizal fungi, 1.7 parts of Streptomyces jingyang, coagulation 1.8 parts of Bacillus, 1.5 parts of Paecilomyces lilacinus.

[0046] First crush the ore soil, first pour granite, basalt, quartzite, such as shale, red sandstone into the crusher for sufficient crushing;

[0047] Then ferment the soil, seal and mix river mud, turf soil, swamp soil, pine needle soil, humus soil, peat, and acetic acid, then inject nitrogen, and then add sucrose solution with a concentration of 65 to mix, treat at room temperature, and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com