Light-weight thermal-insulation concrete material and preparation method thereof

A concrete and lightweight technology, which is applied in the direction of clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve problems that affect the strength of concrete and fail to meet high architectural standards, and achieve increased strength, high strength requirements, and improved microstructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

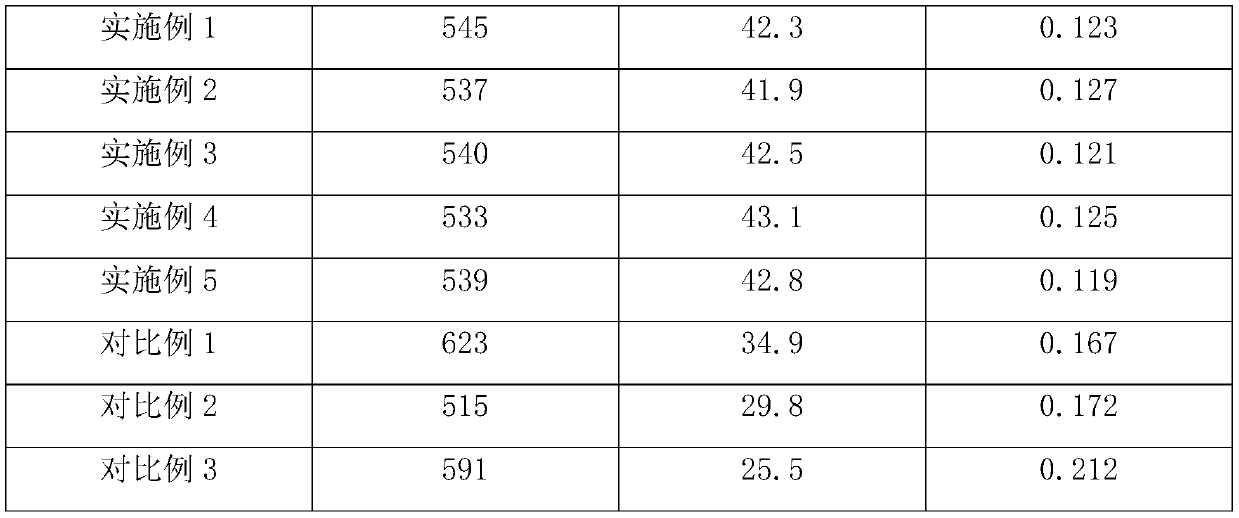

Embodiment 1

[0028] A method for preparing a light-weight heat-preserving concrete material, the steps of which are: adding 0.1 kg of manganese dioxide to 1 kg of hydrogen peroxide with a mass concentration of 30%, adding prefabricated slurry while stirring, stirring evenly, vibrating to form, and curing, that is Obtain the described a kind of lightweight thermal insulation concrete material;

[0029] Wherein, the prefabricated slurry includes three parts: A slurry, B slurry and C slurry. When feeding, add A slurry first, stir evenly, and then add B slurry while stirring, and add B slurry immediately after the feeding is completed. C slurry; the A slurry is prepared by the following method: first add 0.02kg petroleum coke powder and 0.05kg fly ash to 0.1kg water, ball mill, then add the mixture of 0.15kg cement and 0.2kg sand, Stir and mix, continue to add 0.21kg light aggregate, 0.001kg admixture, 0.0002kg ammonium persulfate, and stir evenly to get it. The B slurry is 0.08kg aniline hydr...

Embodiment 2

[0039] A method for preparing a light-weight heat-preserving concrete material, the steps of which are: adding 0.2 kg of manganese dioxide to 1 kg of hydrogen peroxide with a mass concentration of 40%, adding prefabricated slurry while stirring, stirring evenly, vibrating to form, and curing, namely Obtain the described a kind of lightweight thermal insulation concrete material;

[0040] Wherein, the prefabricated slurry includes three parts: A slurry, B slurry and C slurry. When feeding, add A slurry first, stir evenly, and then add B slurry while stirring, and add B slurry immediately after the feeding is completed. C slurry; the A slurry is prepared by the following method: first add 0.03kg petroleum coke powder and 0.06kg fly ash to 0.15kg water, ball mill, then add the mixture of 0.22kg cement and 0.25kg sand, Stir and mix, continue to add 0.24kg light aggregate, 0.002kg admixture, 0.0003kg ammonium persulfate, and stir evenly to get it. The B slurry is 0.11kg aniline hyd...

Embodiment 3

[0050] A method for preparing a light-weight heat-preserving concrete material, the steps of which are: adding 0.2 kg of manganese dioxide to 1 kg of hydrogen peroxide with a mass concentration of 30%, adding prefabricated slurry while stirring, stirring evenly, vibrating to form, and curing, namely Obtain the described a kind of lightweight thermal insulation concrete material;

[0051] Wherein, the prefabricated slurry includes three parts: A slurry, B slurry and C slurry. When feeding, add A slurry first, stir evenly, and then add B slurry while stirring, and add B slurry immediately after the feeding is completed. C slurry; the A slurry is prepared by the following method: first add 0.02kg petroleum coke powder and 0.06kg fly ash to 0.1kg water, ball mill, then add the mixture of 0.22kg cement and 0.2kg sand, Stir and mix, continue to add 0.24kg light aggregate, 0.001kg admixture, 0.0003kg ammonium persulfate, and stir evenly to get it. The B slurry is 0.08kg aniline hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com