Method for decolorizing sugar juice by using magnesium silicate film

A technology of magnesium silicate and sugar juice, which is applied in the purification of sugar juice, the use of physical methods to purify, and the production of sugar, to achieve the effects of no sulfite residue, uniform particle size distribution, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of method that sugar juice is carried out decolouring with magnesium silicate film, comprises the following steps:

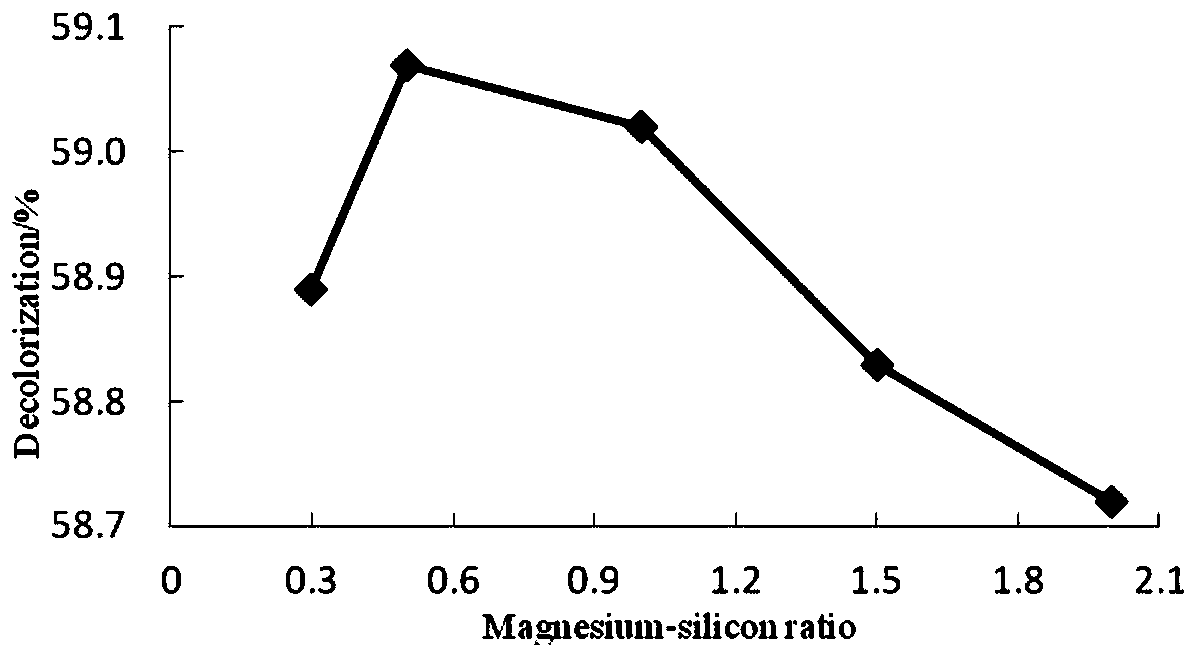

[0019] (1) with MgCl 2 , NH 3 ·H 2 O and silica gel spheres were used as raw materials, and the magnesium silicate raw material was prepared by sacrificial template-hydrothermal synthesis method, that is, 4.8g of SiO 2 Put it in a beaker, add 60mL deionized water and ultrasonically mix it evenly for later use, take 5gNH 4 Cl was placed in another beaker, 60mL of deionized water was added, and MgCl was added at a mass ratio of silicon to magnesium of 1:0.5 while stirring. 2 •6H 2 0, add ammoniacal liquor 3mL and mix uniformly under stirring, then the two solutions are mixed uniformly under stirring, then adjust the pH value of the mixed solution with 0.5mol / L NaOH solution to be 9.3, put into the digestion tank, put into the digestion solution of the reaction solution The tank was placed in an oven, the reaction temperature was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com