Light insulation hose and manufacturing method thereof

A manufacturing method and thermal insulation technology, which is applied in the direction of hoses, thermal insulation, chemical instruments and methods, etc., can solve the problems of conveying pipes without thermal insulation, heavy operation workload, and decreased thermal insulation effect, so as to reduce weight, reduce energy consumption, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

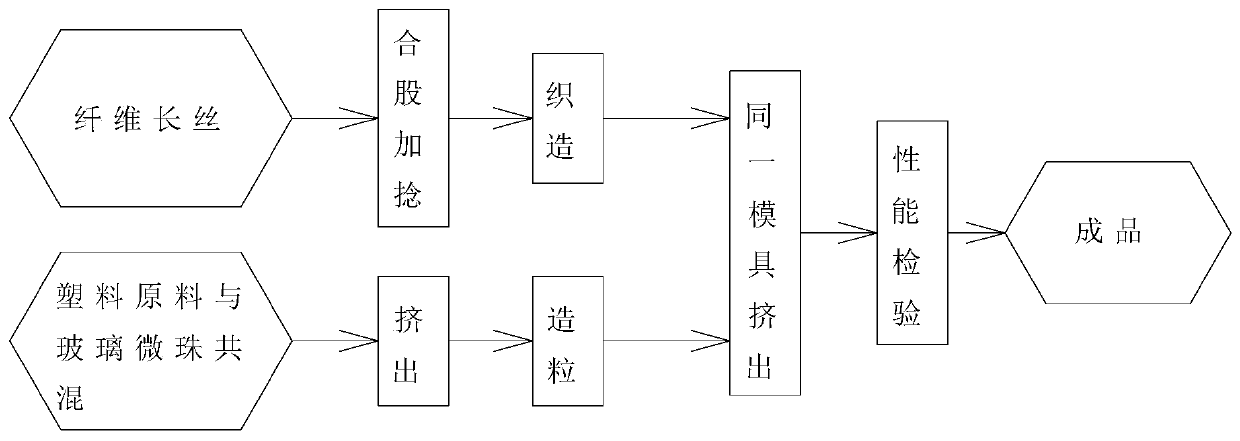

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A light-weight thermal insulation hose, including an inner layer, a reinforcement layer and an outer protective layer arranged sequentially from the inside to the outside, the reinforcement layer is made of fiber filaments through ply twisting and weaving, the inner layer Both the layer and the outer protective layer are made by extruding plastic blends in the same mold, and the plastic blends are composed of 10% hollow glass microspheres and 90% plastic raw materials in terms of mass fraction; Each component of said plastic raw material is specifically in parts by weight: 65 parts of polyethylene, 30 parts of polytetrafluoroethylene, 13 parts of epoxy resin, 3 parts of color masterbatch, 8 parts of filler, 3 parts 1 part of antioxidant, 2 parts of UV absorber, 2 parts of light stabilizer, 1 part of toughening agent.

[0022] Wherein, the hollow glass beads are H25S hollow glass beads, H25HS hollow glass beads or H27 hollow glass beads. The light stabiliz...

Embodiment 2

[0027] Embodiment 2: A light-weight thermal insulation hose, including an inner layer, a reinforcement layer and an outer protective layer arranged sequentially from the inside to the outside, the reinforcement layer is made of fiber filaments through ply twisting and weaving, the inner layer Both the layer and the outer protective layer are made by extruding plastic blends in the same mold, and the plastic blends are composed of 30% hollow glass microspheres and 70% plastic raw materials in terms of mass fraction; Each component of the plastic raw material is specifically in parts by weight: 70 parts of polyethylene, 35 parts of polytetrafluoroethylene, 18 parts of epoxy resin, 7 parts of color masterbatch, 11 parts of filler, 8 parts 5 parts of antioxidant, 5 parts of UV absorber, 7 parts of light stabilizer, 4 parts of toughening agent.

[0028] Wherein, the hollow glass microspheres are H25HS hollow glass microspheres. The light stabilizer is a mixture of light stabilizer...

Embodiment 3

[0033] Embodiment 3: A light-weight thermal insulation hose, including an inner layer, a reinforcement layer and an outer protective layer arranged sequentially from the inside to the outside, the reinforcement layer is made of fiber filaments through ply twisting and weaving, the inner layer Both the layer and the outer protective layer are made by extruding plastic blends in the same mold, and the plastic blends are composed of 20% hollow glass microspheres and 80% plastic raw materials in terms of mass fraction; Each component of said plastic raw material is specifically in parts by weight: 68 parts of polyethylene, 33 parts of polytetrafluoroethylene, 15 parts of epoxy resin, 5 parts of color masterbatch, 9 parts of filler, 7 parts 3 parts of antioxidant, 3 parts of UV absorber, 5 parts of light stabilizer, 3 parts of toughening agent.

[0034] Wherein, the hollow glass microspheres are H27 hollow glass microspheres. The light stabilizer is a mixture of light stabilizer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com