Injection-molded permanent magnetic ferrite magnet and preparation method thereof

A permanent magnet ferrite and magnet technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of easy cracking of magnets, engine overheating, coolant pump failure, etc., and achieves low production cost, injection molding The effect of low temperature and low mold requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

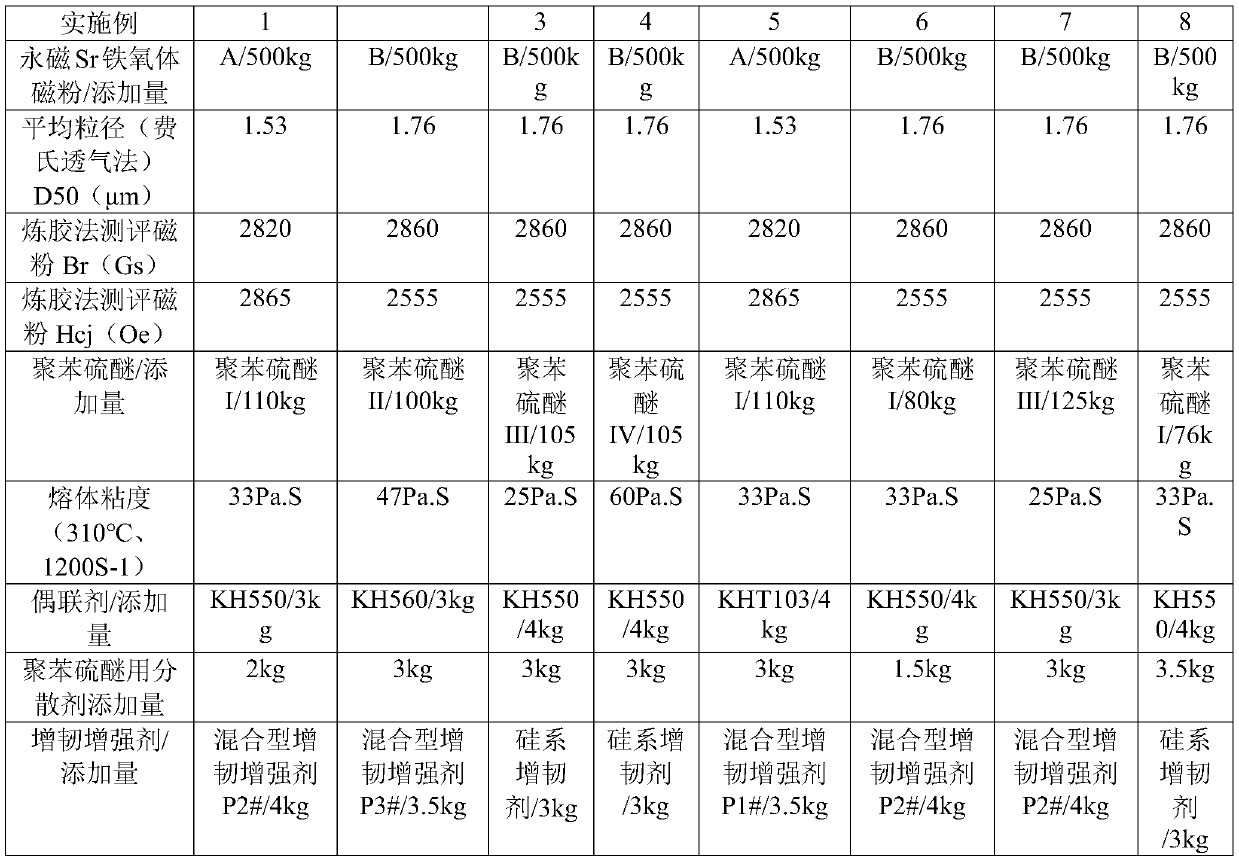

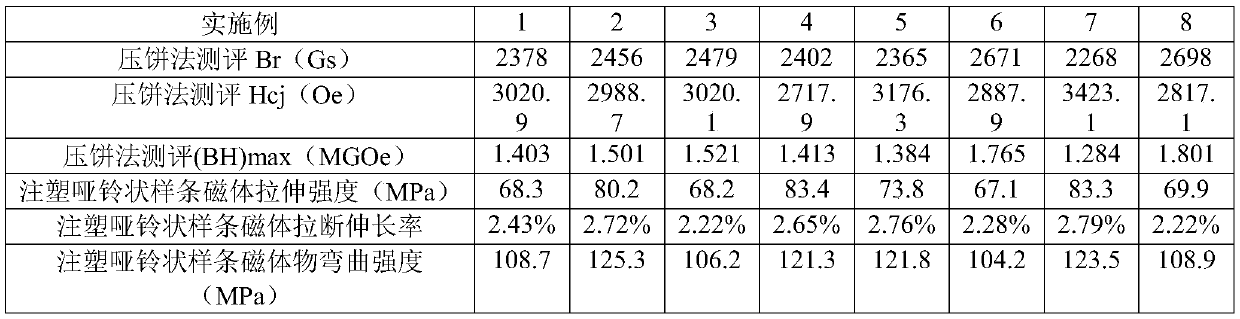

Embodiment 1

[0067] An injection-molded permanent ferrite magnet, made according to the formula shown in Table 1: 500kg of Sr permanent ferrite magnetic powder A, 110kg of polyphenylene sulfide I powder, 3kg of KH550 silane coupling agent, 2kg of polyphenylene sulfide Dispersant for sulfide, 4kg of mixed toughening agent P2#. Among them, the average particle size of Sr permanent ferrite magnetic powder A (Fischer gas permeability method) is 1.53 μm, and the melt viscosity of polyphenylene sulfide I powder (310°C, 1200S -1 ) is 33Pa.S.

[0068] Its preparation method is as follows:

[0069] (1) Magnetic powder surface coupling treatment: 500kg of Sr permanent magnet ferrite magnetic powder A is placed in a high-speed powder mixing tank, and 3kg of KH550 silane coupling agent (1:10 dissolved in isopropanol) is added, mixed at 100°C powder for 50 minutes, and the moisture content of the magnetic powder is controlled within 1000ppm;

[0070] (2) Add 110kg of polyphenylene sulfide I powder a...

Embodiment 2

[0075] An injection-molded permanent ferrite magnet, made according to the formula shown in Table 1: 500kg of Sr permanent ferrite magnetic powder B, 100kg of polyphenylene sulfide II powder, 3kg of KH560 silane coupling agent, 3kg of polyphenylene sulfide II powder Dispersant for sulfide, 3.5kg of mixed toughening agent P3#. Among them, the average particle size of Sr permanent ferrite magnetic powder B (Fischer gas permeability method) is 1.76 μm, and the melt viscosity (310°C, 1200S-1) of polyphenylene sulfide II powder is 47Pa.S.

[0076] Its preparation method is as follows:

[0077] (1) Magnetic powder surface coupling treatment: 500kg of Sr permanent magnet ferrite magnetic powder B is placed in a high-speed powder mixing tank, and 3kg of KH560 silane coupling agent (1:10 ratio is dissolved in isopropanol) is added. Mix the powder at temperature for 50 minutes, and control the moisture content of the magnetic powder within 1000ppm;

[0078] (2) Add 100kg of polyphenyl...

Embodiment 3

[0083] An injection-molded permanent ferrite magnet, made according to the formula shown in Table 1: 500kg of Sr permanent ferrite magnetic powder B, 105kg of polyphenylene sulfide III powder, 4kg of KH550 silane coupling agent, 3kg of polyphenylene sulfide III powder Dispersant for thioether, 3kg of silicon-based toughening agent. Among them, the average particle size of Sr permanent ferrite magnetic powder B (Fischer gas permeability method) is 1.76 μm, and the melt viscosity (310°C, 1200S-1) of polyphenylene sulfide III powder is 25Pa.S.

[0084] Its preparation method is as follows:

[0085] (1) Magnetic powder surface coupling treatment: 500kg of Sr permanent magnet ferrite magnetic powder B is placed in a high-speed powder mixing tank, and 4kg of KH550 silane coupling agent (1:10 ratio is dissolved in isopropanol) is added. Mix the powder at temperature for 50 minutes, and control the moisture content of the magnetic powder within 1000ppm;

[0086](2) Add 105kg of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com