Preparation method of lithium extraction adsorbent

A technology of adsorbent and lithium salt, applied in the field of preparation of lithium extraction adsorbent, can solve the problems of increasing the amount of lithium salt, high insertion rate, difficult to achieve, etc., and achieves the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

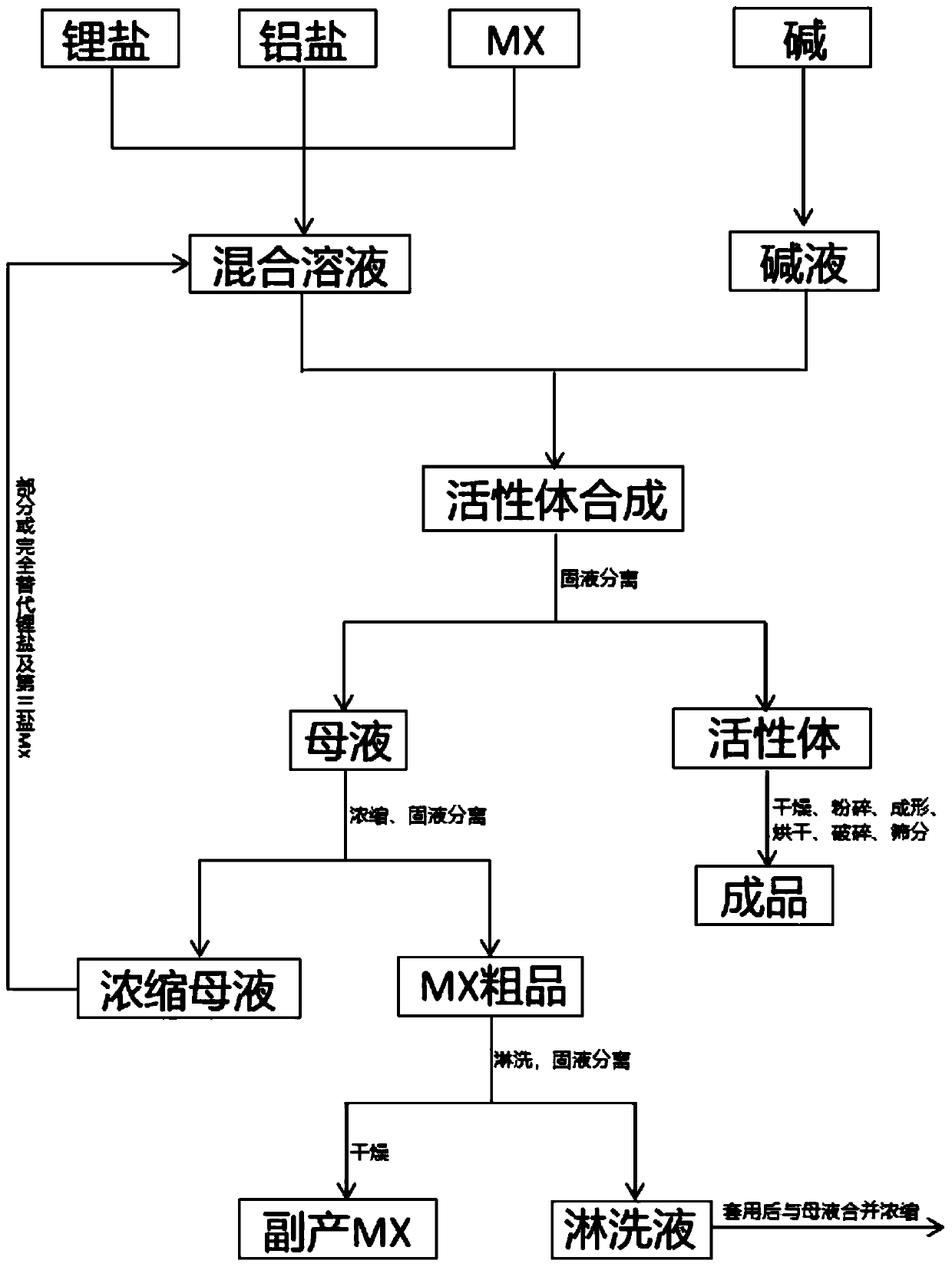

[0031] see figure 1 , the preparation method of a kind of lithium extracting adsorbent of the present invention, comprises the following steps:

[0032] S1, the preparation of the mixed solution, preparing an aqueous solution containing 1-2mol / L aluminum salt, 2-4mol / L lithium salt, and 0-2mol / L third salt MX;

[0033] Lithium salts include lithium chloride, lithium bromide, lithium carbonate, lithium nitrate, lithium sulfate, and the like.

[0034] The aluminum salt has the same anion as the lithium salt, including aluminum chloride, aluminum bromide, aluminum carbonate, aluminum nitrate, aluminum sulfate, potassium aluminum sulfate dodecahydrate, and the like.

[0035] The third salt has the same anion as the lithium salt and the same cation as the base, including sodium salt, potassium salt, ammonium salt, calcium salt, magnesium salt, and the like.

[0036] S2, the preparation of lye, the preparation of an aqueous solution containing 1 to 3 mol / L of alkali;

[0037] The...

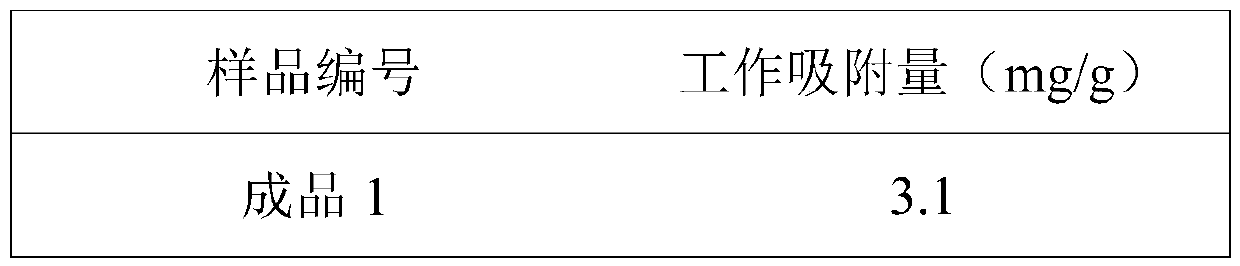

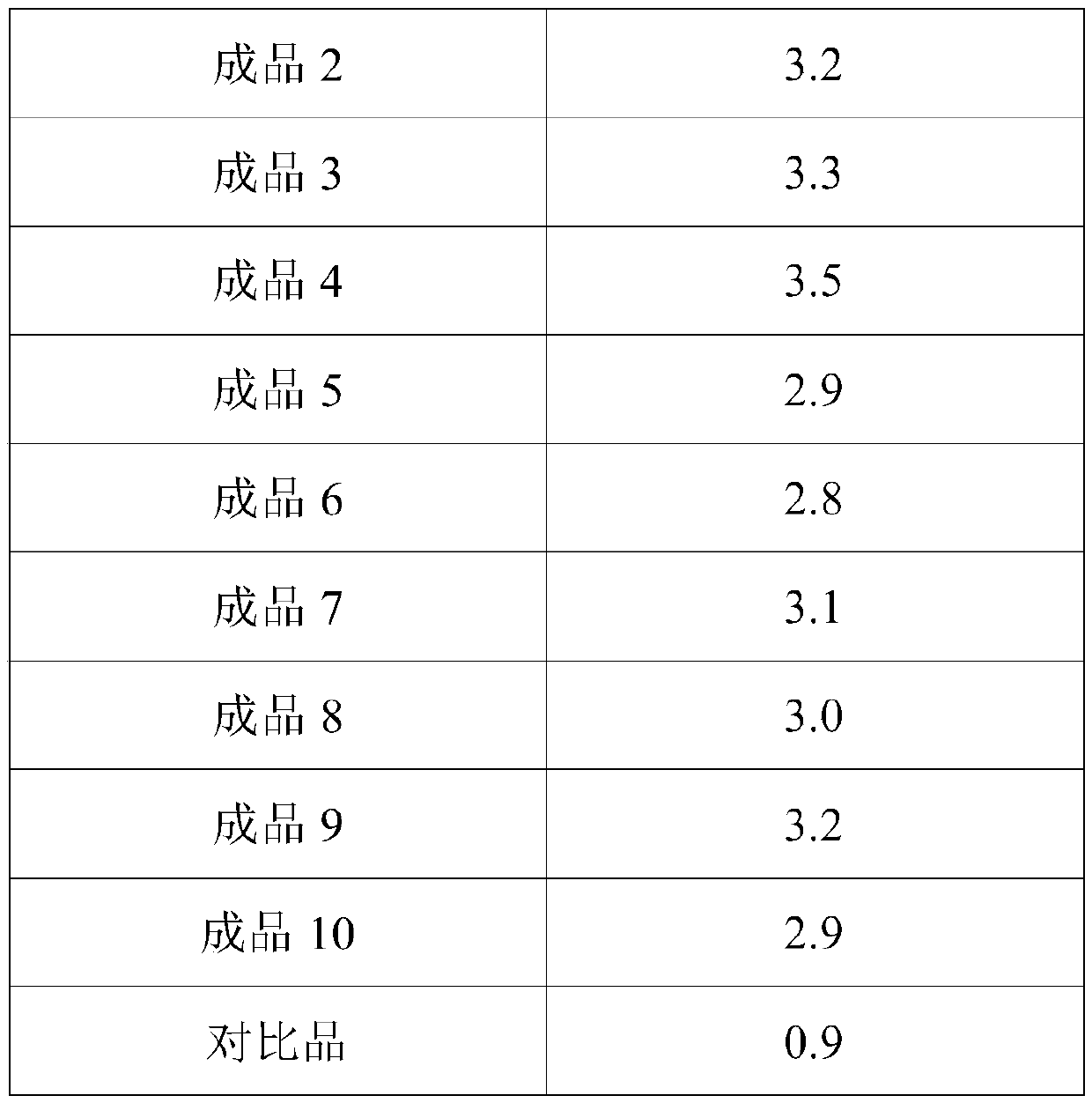

Embodiment 1

[0053] Add 108.5g of lithium chloride, 309.0g of crystalline aluminum chloride, 74.8g of sodium chloride and pure water into a 2L beaker, stir well and transfer to a 5L three-necked flask equipped with mechanical stirring and a thermometer, and raise the temperature to 45°C under stirring Keep warm to obtain a solution containing lithium chloride 2.0mol / L, aluminum chloride 1.0mol / L, and sodium chloride 1.0mol / L. Under this condition, slowly add 1920mL2mol / L sodium hydroxide solution to the flask, and then add The ratio of the amount of sodium hydroxide to aluminum chloride is about 3.00:1, and the reaction is stopped after continuing to stir for 2.0 hours, and the reaction mixture is filtered with suction to obtain clarified mother liquor and wet active body.

[0054] The obtained wet solid was dried at 40° C. for 16.0 h to obtain a dry active body. Crush the dry solid into a 140 mesh powder. Weigh 50.0g of the obtained powder, 4.0g of chlorinated polyvinyl chloride and 20.0...

Embodiment 2

[0056] Measure 3.0L of the clarified mother liquor obtained in Example 1 and put it into a 5L there-necked flask, evaporate and remove 2.5L of water, that is, concentrate 6 times, after the crystals are precipitated overnight, wash with suction to obtain crystals and clear and concentrated mother liquor, the obtained crystals are Sodium chloride, the purity is greater than 95% after drying.

[0057] Weigh 144.9g of crystalline aluminum chloride, measure 300mL of concentrated mother liquor, put it in a 1L beaker, add pure water, stir and transfer it to a 3L three-necked flask equipped with a mechanical stirrer and a thermometer, heat it up to 45°C while stirring, and keep it warm to obtain Contain lithium chloride 2.0mol / L, aluminum chloride 1.0mol / L, sodium chloride 1.1mol / L solution, add 900mL 2mol / L sodium hydroxide solution slowly under this condition, the sodium hydroxide added at this moment and The ratio of aluminum chloride to substance is about 3.00:1. After continuing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com