Inhibitor for direct flotation of high-calcium fluorite and flotation method

A positive flotation and depressant technology, applied in the field of high-calcium fluorite positive flotation, can solve the problems of affecting the recycling of backwater, difficulty in obtaining flotation indicators, and poor selectivity, so as to reduce the increase in collector consumption, Large market application prospect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

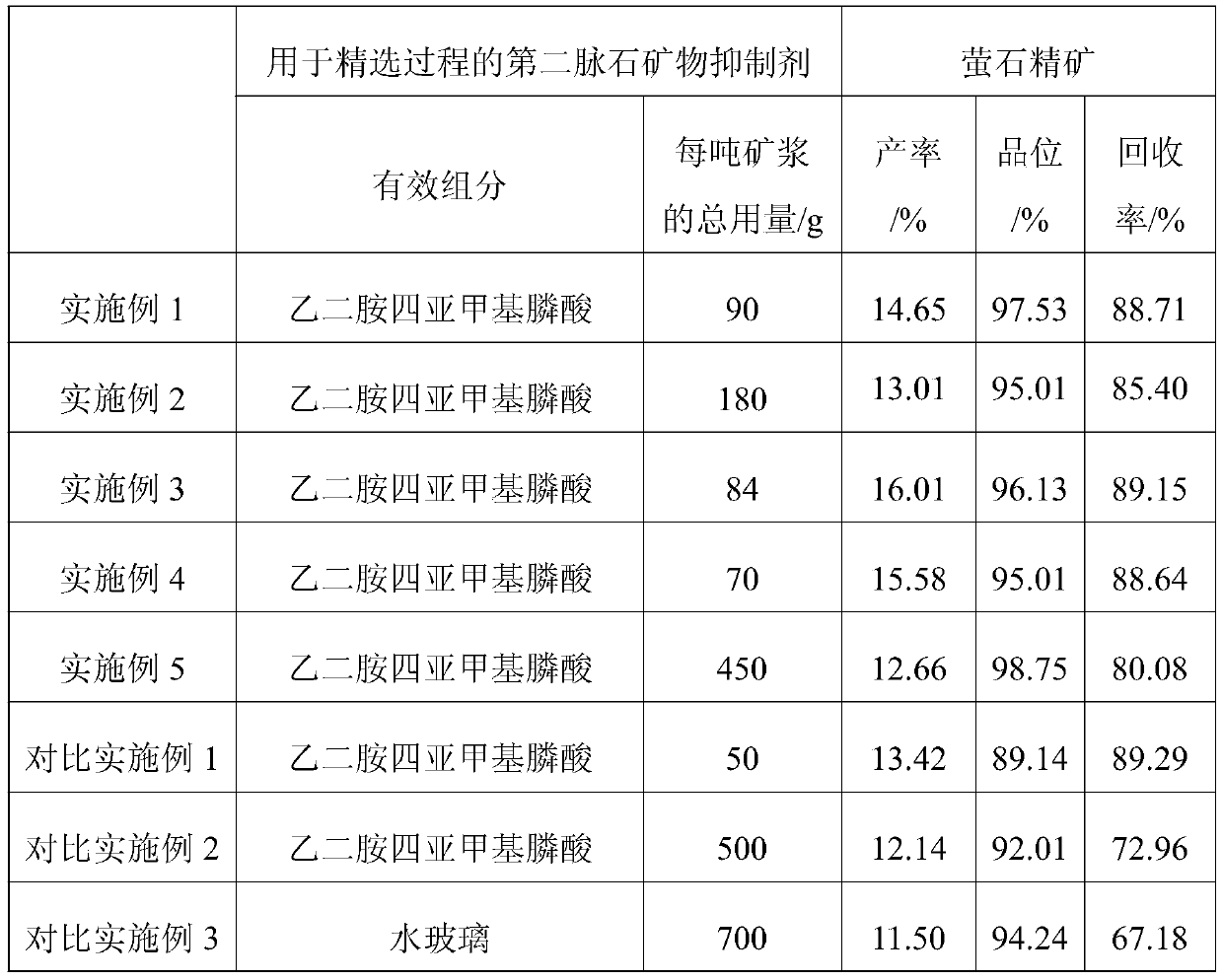

Embodiment 1

[0036] In this example, a high-calcium fluorite mine in Hunan is used as raw material, and the sample mainly contains 16.11% CaF 2 , 13.56% CaCO 3 . The main gangue minerals are calcite, etc., among which calcite has a high content and is difficult to sort.

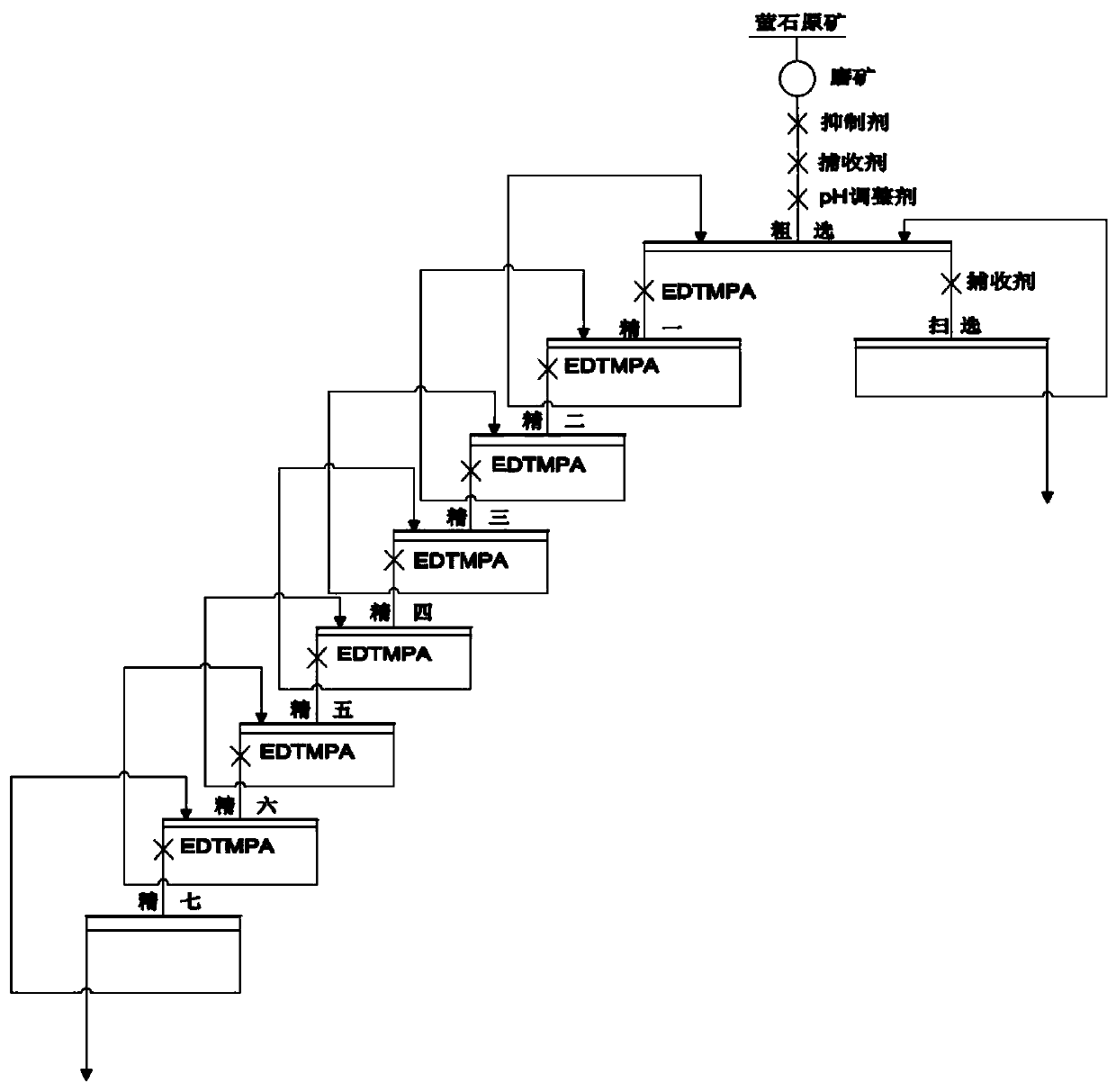

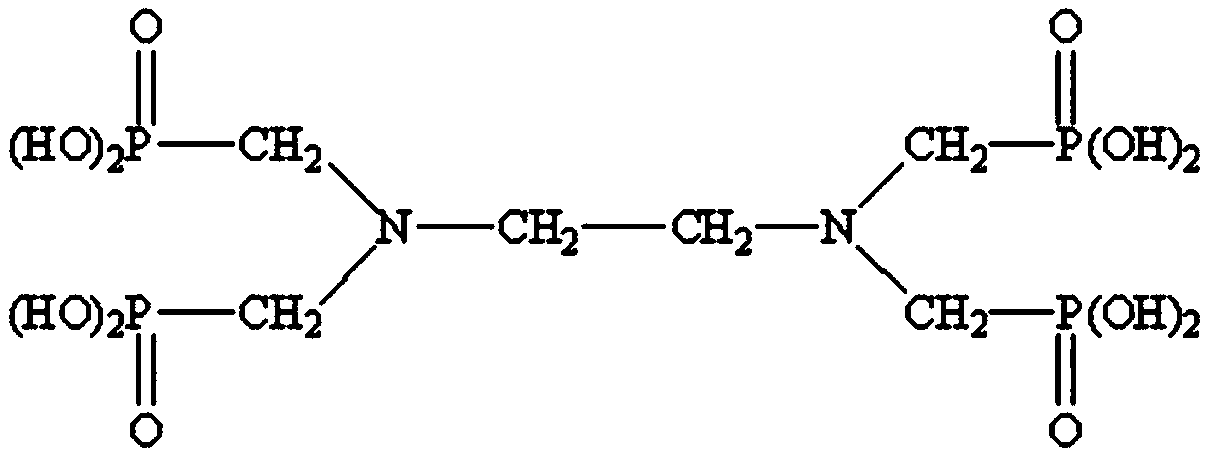

[0037] see figure 1 , a high-calcium fluorite positive flotation method, specifically comprising the steps of:

[0038] 1) Crush the raw fluorite ore, and use a ball mill to grind the ore to a fineness of -0.074mm, which accounts for 75%-85% of the raw ore quality;

[0039] 2) Prepare the ore powder into a slurry, add 1000g of water glass as the first gangue mineral inhibitor to each ton of the slurry, stir for 5 minutes, then add 300g of sodium oleate as a collector, and adjust the slurry with hydrochloric acid after stirring for 3 minutes The pH value is 6-8;

[0040] 3) Stir and aerate for 5 minutes for flotation, the aeration volume is 0.2m 3 / h, get fluorite coarse concentrate after one roughing and one sweepin...

Embodiment 2

[0043] In this example, a high-calcium fluorite ore in Henan is used as raw material, and the sample mainly contains 14.66% CaF 2 , 19.23% CaCO 3 . The main gangue minerals are calcite, etc., among which calcite has a high content and is difficult to sort.

[0044] The positive flotation method used in this embodiment is basically the same as that of Example 1, the only difference being that the ethylenediaminetetramethylene (ethylenediaminetetramethylene) corresponding to each ton of pulp in each selection in step 4) in this embodiment is selected from one to selected four The amount of base phosphonic acid is 30g, and the amount of ethylenediaminetetramethylene phosphonic acid corresponding to each ton of pulp in each selection from the fifth to the seventh is 20g.

Embodiment 3

[0046] In this example, a high-calcium fluorite mine in Fujian is used as raw material, and the sample mainly contains 25.46% CaF 2 , 11.71% CaCO 3 . The main gangue minerals are calcite, etc., among which calcite has a high content and is difficult to sort.

[0047] The positive flotation method used in this embodiment is basically the same as that of Example 1, the only difference being that the ethylenediaminetetramethylene (ethylenediaminetetramethylene) corresponding to each ton of pulp in each selection in step 4) in this embodiment is selected from one to selected four The amount of base phosphonic acid is 15g, and the amount of ethylenediaminetetramethylene phosphonic acid corresponding to each ton of pulp in each of the beneficiation five to seven is 8g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com