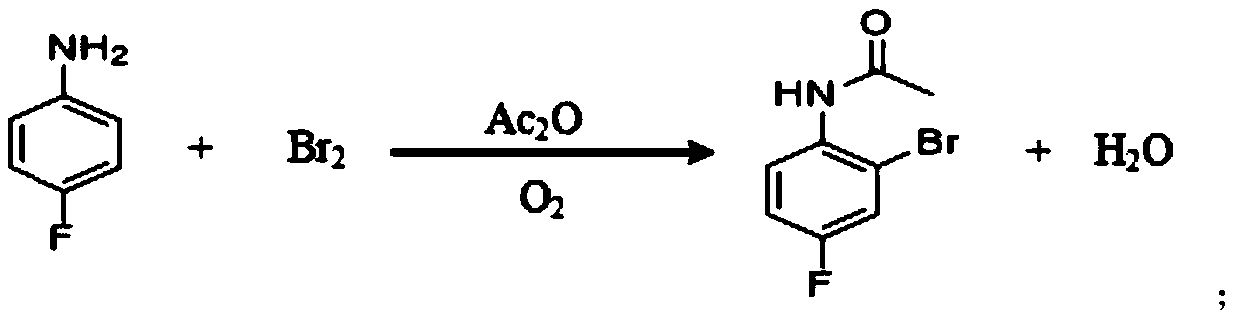

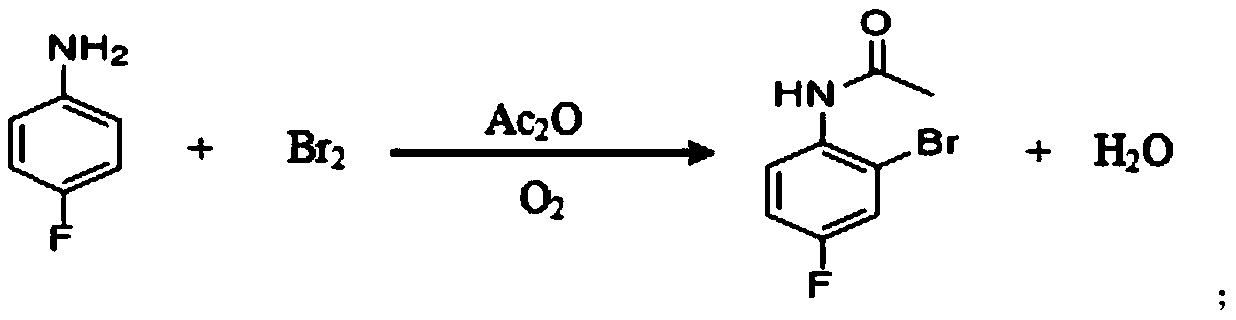

Synthesis method of sulfur-free 2-bromo-4-fluoroacetanilide

The technology of a fluoroacetanilide and a synthesis method is applied in the field of synthesis of sulfur-free 2-bromo-4-fluoroacetanilide, can solve the problems of inconvenience in subsequent use, consumes a lot of washing water, and is not environmentally friendly, and achieves fewer reaction steps and higher yield High, reaction time reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 200L of chlorobenzene, 100L of p-fluoroaniline, and 1kg of palladium catalyst in a 1000L kettle, stir evenly for use, raise the temperature to 50 degrees Celsius, add acetic anhydride dropwise through the high-level tank, and bromine passes through the vaporizer and gas distributor to control the concentration of acetic anhydride and bromine. The adding speed is a molar ratio of 1:2, the molar ratio of acetic anhydride to p-fluoroaniline is 1:1.05, and the molar ratio of bromine to p-fluoroaniline is 1:2.1. After the dropwise addition, the temperature was raised to 70 degrees centigrade and kept for 4 hours to react. During the reaction, air was bubbled at a rate of 0.5 L / min to replenish oxygen. After the reaction, the palladium catalyst was removed by filtration. Then add 200L of 10% sodium formate, and more precipitates are generated at this time. After solid-liquid separation, the solid is 2-bromo-4-fluoroacetanilide, and the content of 2-bromo-4-fluoroacetanilid...

Embodiment 2

[0024] Add 200L of chlorobenzene, 100L of p-fluoroaniline, and 1kg of palladium catalyst in a 1000L kettle, stir evenly for use, raise the temperature to 50 degrees Celsius, add acetic anhydride dropwise through the high-level tank, and bromine passes through the vaporizer and gas distributor to control the concentration of acetic anhydride and bromine. The adding speed is a molar ratio of 1:2, the molar ratio of acetic anhydride to p-fluoroaniline is 1:1.05, and the molar ratio of bromine to p-fluoroaniline is 1:2.1. After the dropwise addition, the temperature was raised to 70 degrees centigrade and kept for 4 hours to react. During the reaction, air was bubbled at a rate of 0.5 L / min to replenish oxygen. After the reaction, the palladium catalyst was removed by filtration. Then add 200L of 10% sodium oxalate, more precipitates are generated at this time, after solid-liquid separation, the solid is 2-bromo-4-fluoroacetanilide, the content of 2-bromo-4-fluoroacetanilide is hig...

Embodiment 3

[0026] Add 200L of chlorobenzene, 100L of p-fluoroaniline, and 1kg of palladium catalyst in a 1000L kettle, stir evenly for use, raise the temperature to 50 degrees Celsius, add acetic anhydride dropwise through the high-level tank, and bromine passes through the vaporizer and gas distributor to control the concentration of acetic anhydride and bromine. The adding speed is a molar ratio of 1:1, the molar ratio of acetic anhydride to p-fluoroaniline is 1:1.05, and the molar ratio of bromine to p-fluoroaniline is 1:1.05. After the dropwise addition, the temperature was raised to 70 degrees centigrade and kept for 4 hours to react. During the reaction, air was bubbled at a rate of 0.5 L / min to replenish oxygen. After the reaction, the palladium catalyst was removed by filtration. Then add 200L of 10% sodium formate, and more precipitates are generated at this time. After solid-liquid separation, the solid is 2-bromo-4-fluoroacetanilide, and the content of 2-bromo-4-fluoroacetanili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com