Weather-proof paint film protective layer aluminum product and surface treatment method thereof

A technology for surface treatment and aluminum products, which is applied in the field of aluminum products, can solve the problems of low adhesion, poor corrosion resistance, and increased production costs of electrophoretic coatings, achieve improvement in filiform corrosion, improve performance indicators, and solve low adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

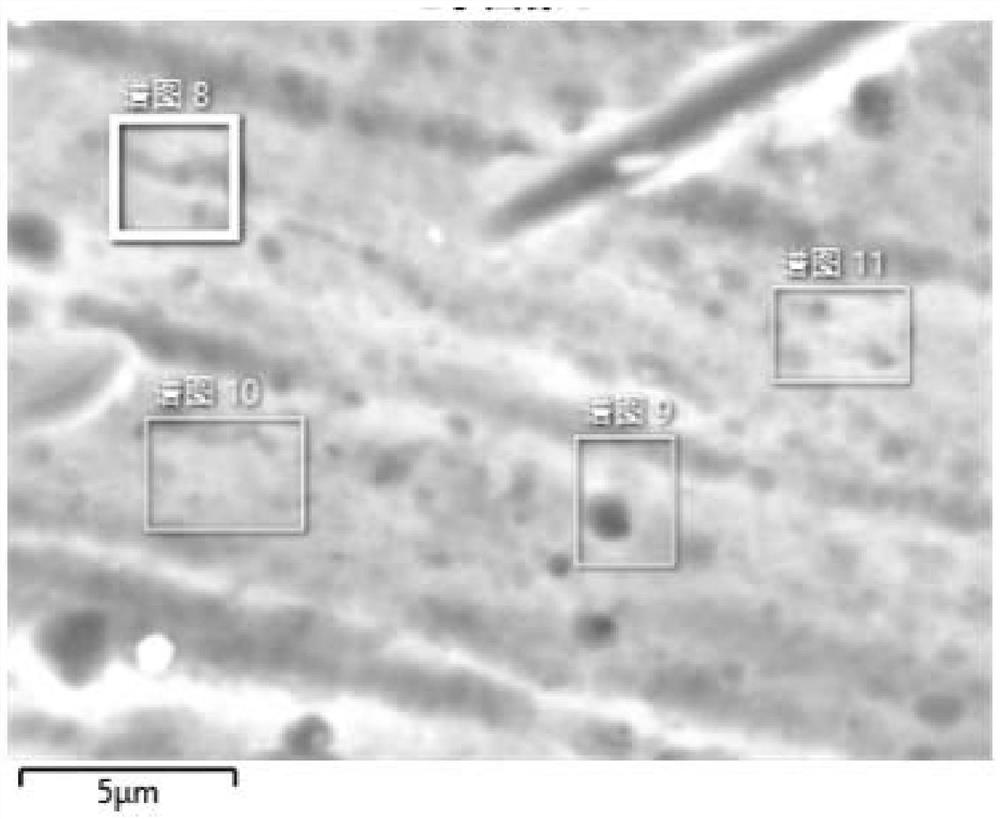

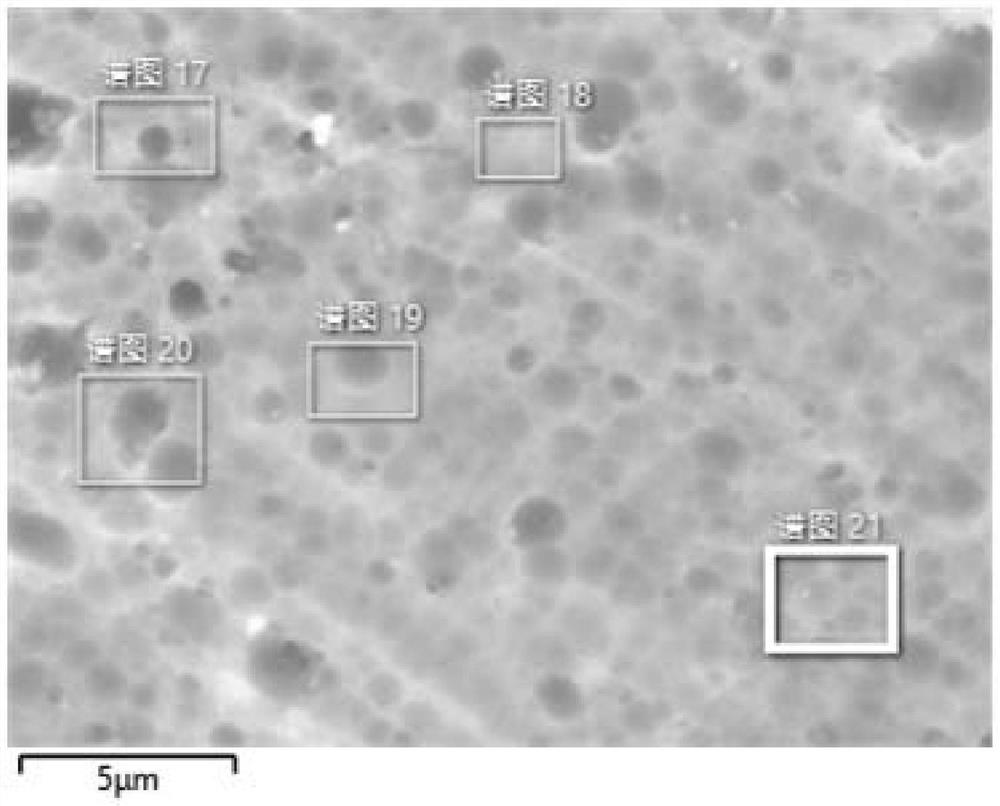

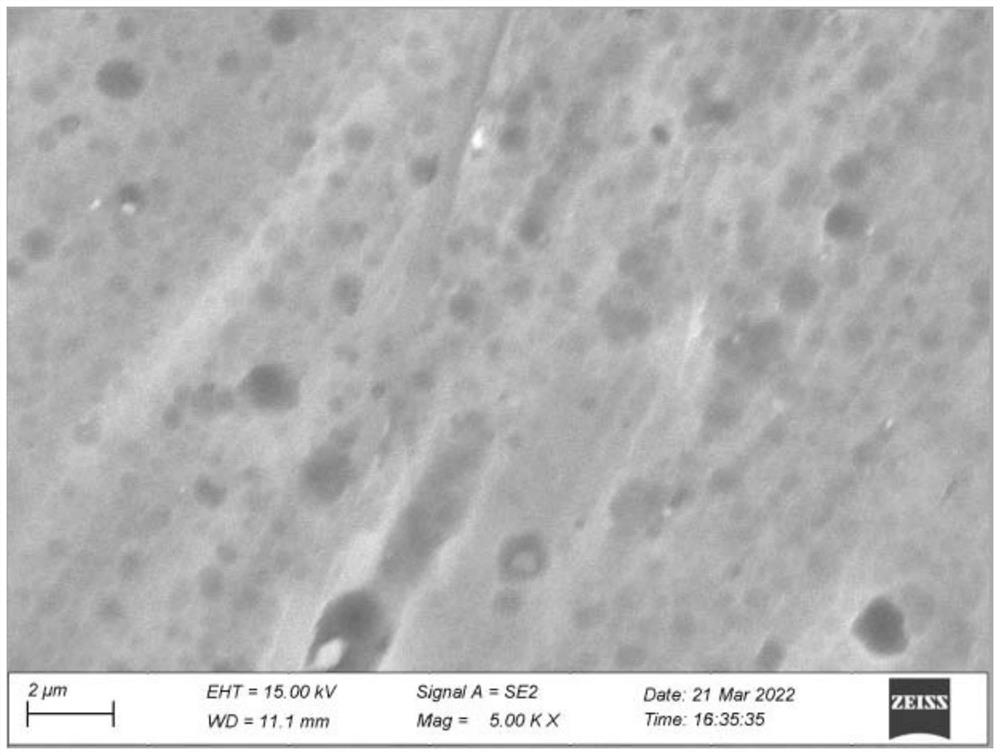

[0072] A weather-resistant paint film protective layer aluminum product, the surface of the aluminum product is provided with an electrophoretic paint protective layer formed by electrophoresis, and a layer of 0.2 μm thick is also arranged between the surface of the aluminum product and the electrophoretic paint protective layer. Chemical conversion film; the chemical conversion film is a chemical conversion film formed after the aluminum product is degreasing, polished and chemically converted; the chemical conversion film is a chemical conversion film containing aluminum oxalate, aluminum fluoride, sodium aluminum hexafluoride, zirconium Chemical conversion coatings of salts or titanium salts and zirconium-titanium double salts.

Embodiment 2

[0074] A weather-resistant paint film protective layer aluminum product, the surface of the aluminum product is provided with an electrophoretic paint protective layer formed by electrophoresis, and a layer of 2.0 μm thick is also arranged between the surface of the aluminum product and the electrophoretic paint protective layer. Chemical conversion film; the chemical conversion film is a chemical conversion film formed after the aluminum product is degreasing, polished and chemically converted; the chemical conversion film is composed of aluminum oxalate, aluminum fluoride, and sodium aluminum hexafluoride, including NaZrF 3 (OH) 2 ·H 2 O and NaZrF 3 O 2H 2 Zirconium salt or titanium salt Al of O 2 O 3 ·4AlOF·TiO·H 2 Chemical conversion coating of O and zirconium-titanium double salt.

Embodiment 3

[0076] A weather-resistant paint film protective layer aluminum product, the surface of the aluminum product is provided with a spray paint protective layer formed by spray painting, and a layer of chemical exchange with a thickness of 4.0 μm is also arranged between the surface of the aluminum product and the spray paint protective layer. Conversion film; the chemical conversion film is a chemical conversion film formed after the aluminum product is degreasing, polished and chemically converted; the chemical conversion film is composed of aluminum oxalate, aluminum fluoride, sodium aluminum hexafluoride, including NaZrF 3 (OH) 2 ·H 2 O and NaZrF 3 O 2H 2 Zirconium salt or titanium salt Al of O 2 O 3 ·4AlOF·TiO·H 2 Chemical conversion coating of O and zirconium-titanium double salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com