Waterborne polyurethane-acrylate hybrid resin and preparation method thereof, and application in leather finishing agent

A technology of water-based polyurethane and acrylate, applied in the direction of coating, etc., can solve the problems of poor anti-adhesive performance of paint film surface, poor filler coating performance and unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Add 68g HMDI (dicyclohexylmethane diisocyanate), 110g PNA2000 (polyneopentyl adipate diol), heat up to 80°C for 1 hour, then cool down to about 60°C and add 3.8g trimethylolpropane, 12.6g Dimethylol propionic acid, 48g of acetone, heated up to 75°C for reaction, sampling and measuring NCO every 1 hour, until the NCO reached below 2%, stop the reaction.

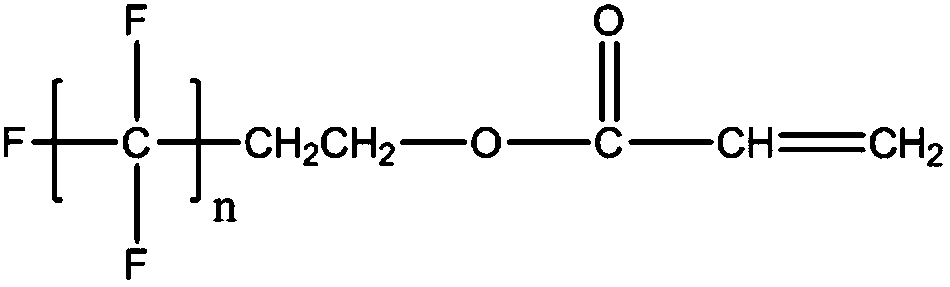

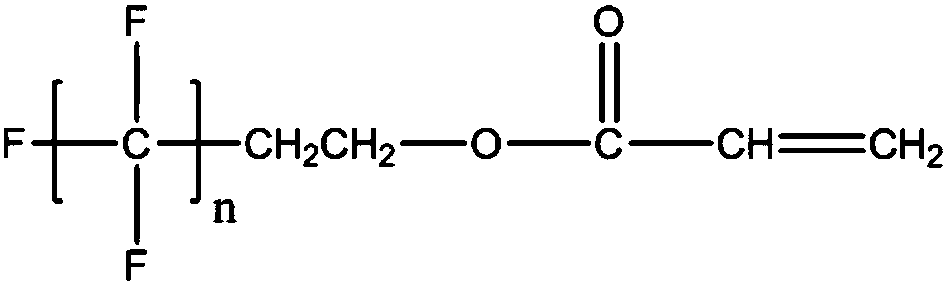

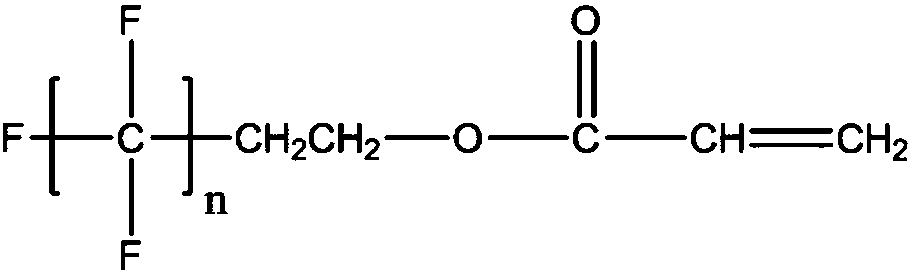

[0110] Cool down to below 60°C (between 50-60°C), add 76g of acetone, 32g of butyl acrylate, 104.5g of methyl methacrylate, 39g of styrene, and 19.5g of perfluoroalkyl ethyl acrylate, mix and dissolve.

[0111] Cool down to below 40°C and add 9.5g of triethylamine, and neutralize for 3 minutes.

[0112] The prepared prepolymer was poured into a dispersion cup, and 585 g of water was added under a high-speed shear condition of 1500 r / min to obtain a water-based polyurethane-acrylate mixed emulsion.

[0113] Transfer the emulsion to a four-necked flask equipped with a reflux condenser, a thermometer and a mechanical st...

Embodiment 2

[0116] Add 68g HMDI (dicyclohexylmethane diisocyanate), 110g PNA2000 (polyneopentyl adipate diol), heat up to 80°C for 1 hour, then cool down to about 60°C and add 3.8g trimethylolpropane, 12.6g Dimethylol propionic acid, 48g of acetone, heated up to 75°C for reaction, sampling and measuring NCO every 1 hour, until the NCO reached below 2%, stop the reaction.

[0117] Cool down to below 60°C (between 50-60°C), add 76g of acetone, 32g of butyl acrylate, 122g of methyl methacrylate, 39g of styrene, 2g of perfluoroalkyl ethyl acrylate, mix and dissolve.

[0118] Cool down to below 40°C and add 9.5g of triethylamine, and neutralize for 3 minutes.

[0119] The prepared prepolymer was poured into a dispersion cup, and 585 g of water was added under a high-speed shear condition of 1500 r / min to obtain a water-based polyurethane-acrylate mixed emulsion.

[0120] Transfer the emulsion to a four-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, ra...

Embodiment 3

[0123] Add 68g HMDI (dicyclohexylmethane diisocyanate), 110g PNA2000 (polyneopentyl adipate diol), heat up to 80°C and react for 1h, then cool down to about 60°C and add 3.8g trimethylolpropane, 12.6g Dimethylol propionic acid, 48g of acetone, heated up to 75°C for reaction, sampling and measuring NCO every 1 hour, until the NCO reached below 2%, stop the reaction.

[0124] Cool down to below 60°C (between 50-60°C), add 76g of acetone, 32g of butyl acrylate, 88g of methyl methacrylate, 39g of styrene, and 36g of perfluoroalkyl ethyl acrylate, mix and dissolve.

[0125] Cool down to below 40°C and add 9.5g of triethylamine, and neutralize for 3 minutes.

[0126]The prepared prepolymer was poured into a dispersion cup, and 585 g of water was added under a high-speed shear condition of 1500 r / min to obtain a water-based polyurethane-acrylate mixed emulsion.

[0127] Transfer the emulsion to a four-necked flask equipped with a reflux condenser, a thermometer and a mechanical st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com