Preparation method of self-temperature-regulating water-based silicon-acrylic paint

A water-based silicone and coating technology, applied in the direction of coating, etc., can solve the problems of difficult to form industrial production, difficult to control the shape of microcapsules, difficult to control the reaction, etc., and achieve the effect of easy control, good dispersion and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

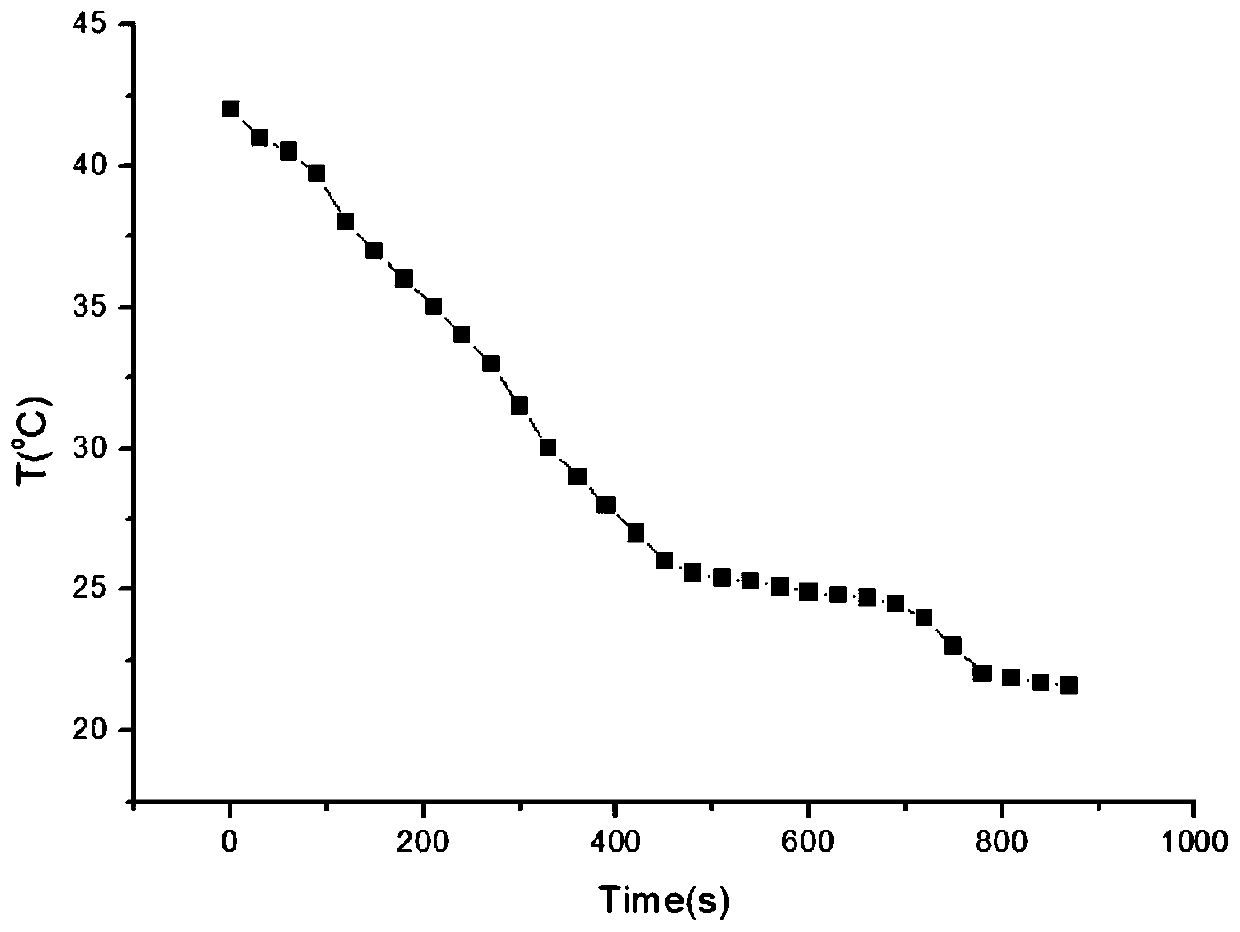

[0029] A kind of preparation method of self-adjusting temperature water-based silicone acrylic coating adopts improved suspension polymerization method, and concrete steps are as follows:

[0030] (1) At 45°C, add 1 g of dispersant styrene-maleic anhydride copolymer sodium salt and 50 mL of water into the reaction kettle, and stir until completely dissolved.

[0031] (2) Accurately weigh 6 g of ethyl methacrylate, 1.5 g of methyl methacrylate, 2.5 g of divinylbenzene, 1.5 g of paraffin, and 0.3 g of lauryl peroxide and mix them evenly.

[0032] (3) Add the mixture of step 2 into the reactor of step 1, and continue stirring for 1 hour at 1000 rpm. Then, reduce the rotational speed to 250 rpm, raise the temperature to 75°C, react for 3.5 hours, raise the temperature to 80°C, and continue the reaction for 1 hour.

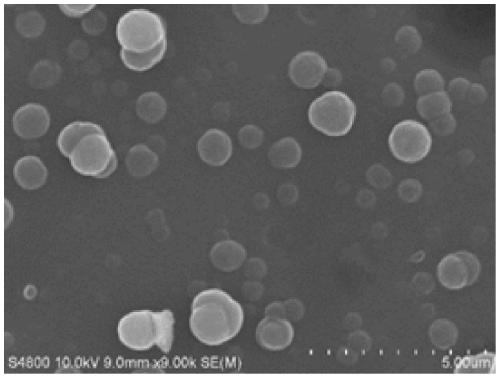

[0033] (4) The product was suction filtered while it was hot, washed three times with water and ethanol respectively, and dried in a blast oven at 50° C. for 24 hours...

Embodiment 2

[0040] A kind of preparation method of self-adjusting temperature water-based silicone acrylic coating adopts improved suspension polymerization method, and concrete steps are as follows:

[0041] (1) At 45°C, add 1.5 grams of dispersant styrene-maleic anhydride copolymer sodium salt and 50 mL of water into the reaction kettle, and stir until completely dissolved.

[0042] (2) Accurately weigh 6 g of ethyl methacrylate, 1.5 g of methyl methacrylate, 2.5 g of divinylbenzene, 1.0 g of stearic acid, and 0.3 g of lauryl peroxide and mix them evenly.

[0043] (3) Add the mixture of step 2 into the reactor of step 1, and continue stirring for 1 hour at 3000 rpm. Then, reduce the rotational speed to 500 rpm, raise the temperature to 75° C., react for 3.5 hours, raise the temperature to 80° C., and continue the reaction for 1 hour.

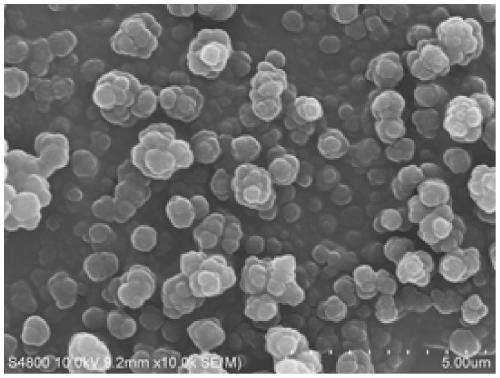

[0044] (4) The product was suction filtered while it was hot, washed three times with water and ethanol respectively, and dried in a blast oven at 50° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com