A kind of hysteresis phase change energy storage material and its preparation method

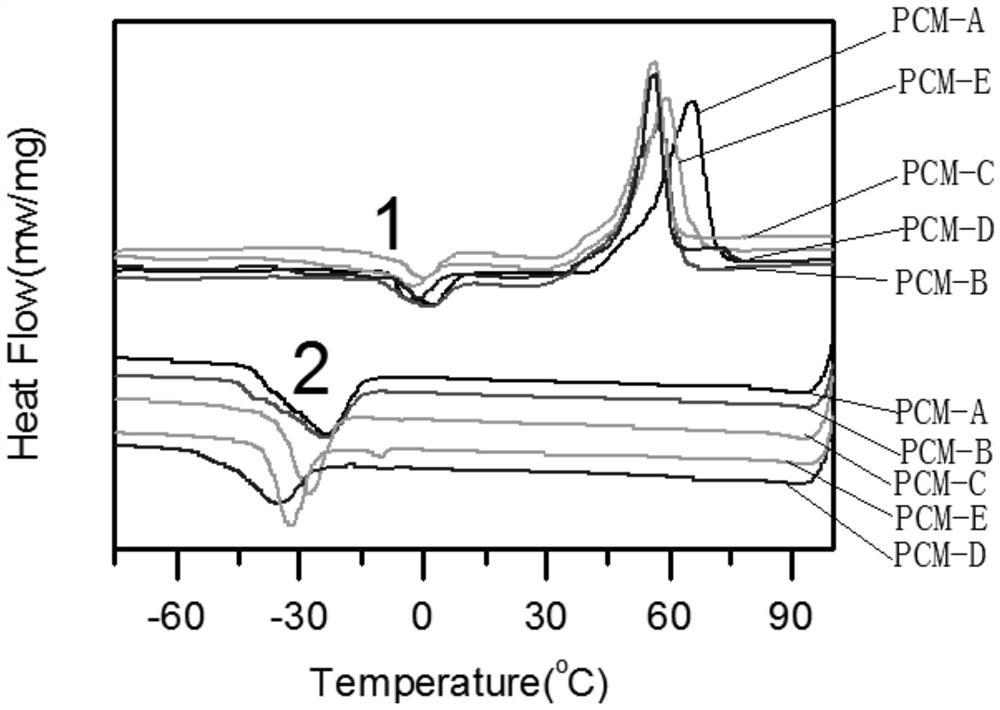

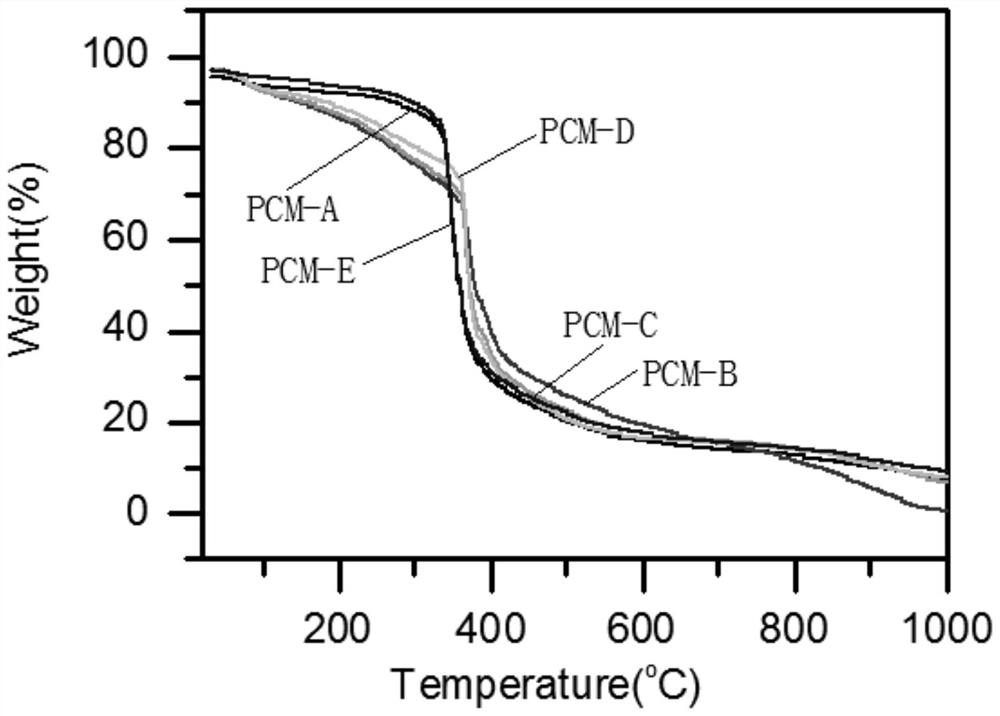

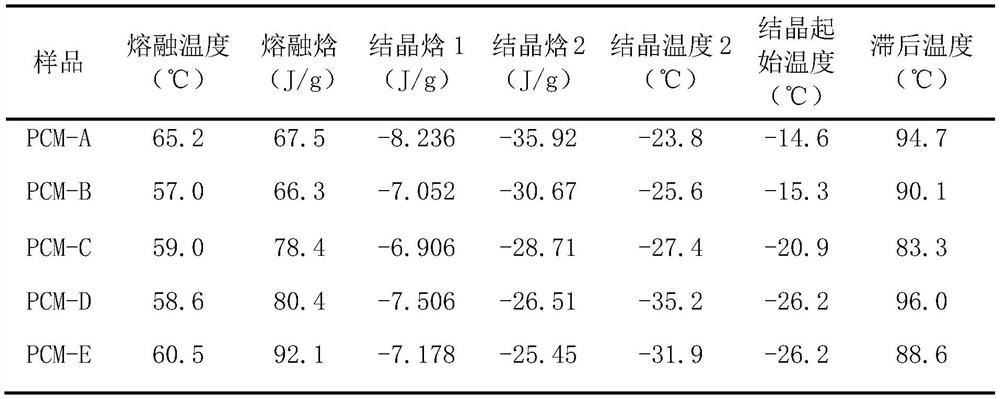

A phase change energy storage material and hysteresis technology, which are applied in heat exchange materials, chemical instruments and methods, etc., can solve the problem that phase change energy storage materials do not have temperature hysteresis, and achieve high thermal stability and simple preparation. , The effect of excellent energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 16 g of 4-benzylphenylethyl caprate, 9 g of 2-naphthol benzyl ether, 4 g of styrene-maleic anhydride copolymer, 45 g of prepolymer of urea-formaldehyde resin, 20 g of ammonium chloride solution and 20 g of water. Mix 4-benzylphenylethyl decanoate and 2-naphthol benzyl ether uniformly, and heat to 100°C to obtain a molten mixture. Add styrene maleic anhydride copolymer emulsifier and water to the molten mixture for emulsification at a temperature of 70°C, then add the prepolymer of urea-formaldehyde resin, and then add ammonium chloride solution. After reacting for 3 hours, at 7000r / min Centrifuge under the action of a centrifuge for 30 minutes, remove the supernatant, and place the lower sediment in a 100°C drying oven to dry to obtain hysteretic phase-change energy storage material powder.

Embodiment 2

[0029] Weigh 18g of 4-benzylphenylethyl caprate, 7g of 1,2-diphenoxyethane, 5g of styrene-maleic anhydride copolymer, 50g of prepolymer of urea-formaldehyde resin, 15g of ammonium chloride solution and 15g of water. Mix 4-benzylphenylethyl decanoate and 1,2-diphenoxyethane evenly, and heat to 100°C to obtain a molten mixture. Add styrene-maleic anhydride copolymer emulsifier and water to the molten mixture for emulsification at a temperature of 70°C, then add the prepolymer of urea-formaldehyde resin, and then add ammonium chloride solution, and react for 1 hour. Centrifuge under the action of a centrifuge for 30 minutes, remove the supernatant, and place the lower sediment in a 100°C drying oven to dry to obtain hysteretic phase-change energy storage material powder.

Embodiment 3

[0031] Weigh 15 g of 4-benzylphenylethyl caprate, 10 g of bis-xylylethane, 4 g of styrene-maleic anhydride copolymer, 48 g of prepolymer of urea-formaldehyde resin, 18 g of ammonium chloride solution and 18 g of water. Mix 4-benzylphenylethyl decanoate and bis-xylylethane evenly, and heat to 100°C to obtain a molten mixture. Add styrene maleic anhydride copolymer emulsifier and water to the molten mixture for emulsification at a temperature of 70°C, then add the prepolymer of urea-formaldehyde resin, and then add ammonium chloride solution. After reacting for 3 hours, at 7000r / min Centrifuge under the action of a centrifuge for 30 minutes, remove the supernatant, and place the lower sediment in a 100°C drying oven to dry to obtain hysteretic phase-change energy storage material powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com