Preparation method for micrometer SiC particle reinforced aluminum matrix composite material

A technology for particle-reinforced aluminum and composite materials, which is applied in the field of preparation of aluminum-based composite materials, can solve the problems of uneven distribution of particles in semi-solid stirring casting, difficulty in meeting production requirements and high porosity of castings, and achieves uniform macroscopic distribution and optimization. Microstructure, effect of low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

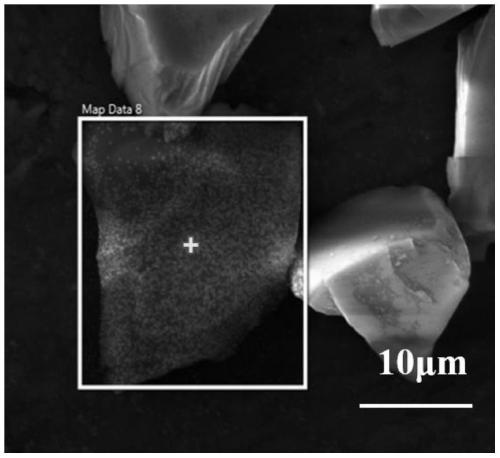

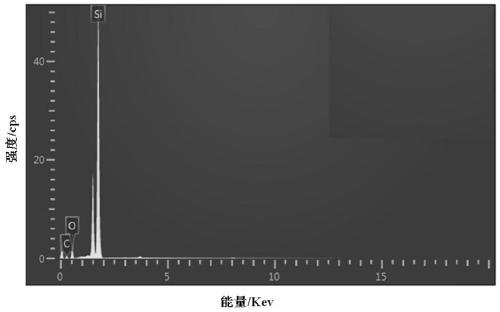

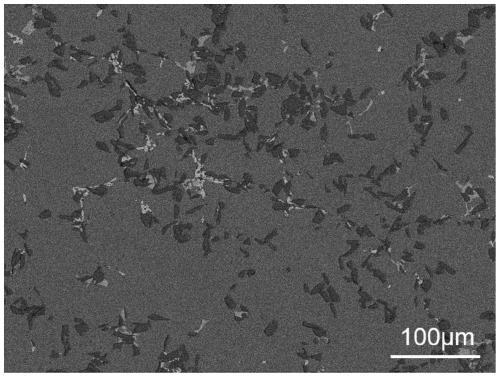

[0028] Specific implementation mode 1: This implementation mode is a preparation method of a micron SiC particle reinforced aluminum matrix composite material, which is specifically carried out according to the following steps:

[0029] 1. Surface treatment of SiC particles: completely submerge SiC particles in HF aqueous solution with a volume fraction of 10%, ultrasonically clean them for 1h to 3h, then let them stand until SiC particles are completely precipitated, take out SiC particles, and wash SiC particles with distilled water until The washing liquid is neutral, and then oxidize the surface of SiC particles by high-temperature roasting. The temperature of high-temperature roasting is 800 ° C to 1300 ° C, the roasting time is 1 h to 10 h, cooled to room temperature, and sealed for storage;

[0030] 2. Semi-solid stirring and ultrasonic: remove the oxide layer on the surface of 2024 aluminum alloy, then heat the 2024 aluminum alloy to 700 ℃ ~ 800 ℃ in a protective atmosp...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that the protective atmosphere described in step 2 is argon. Others are the same as the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the method for refining and removing slag described in step two is: add hexachloroethane to liquid aluminum under protective atmosphere, and in protective atmosphere and 700°C to 800°C for 20 minutes, the mass of hexachloroethane is 0.6% of the mass of liquid aluminum. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com