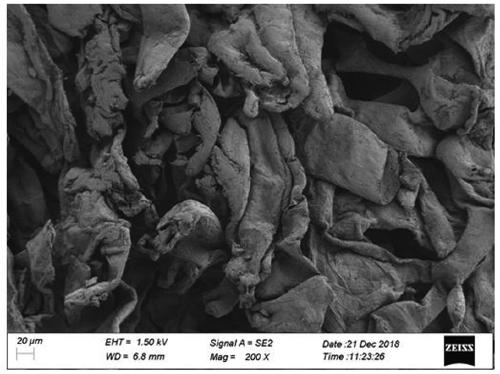

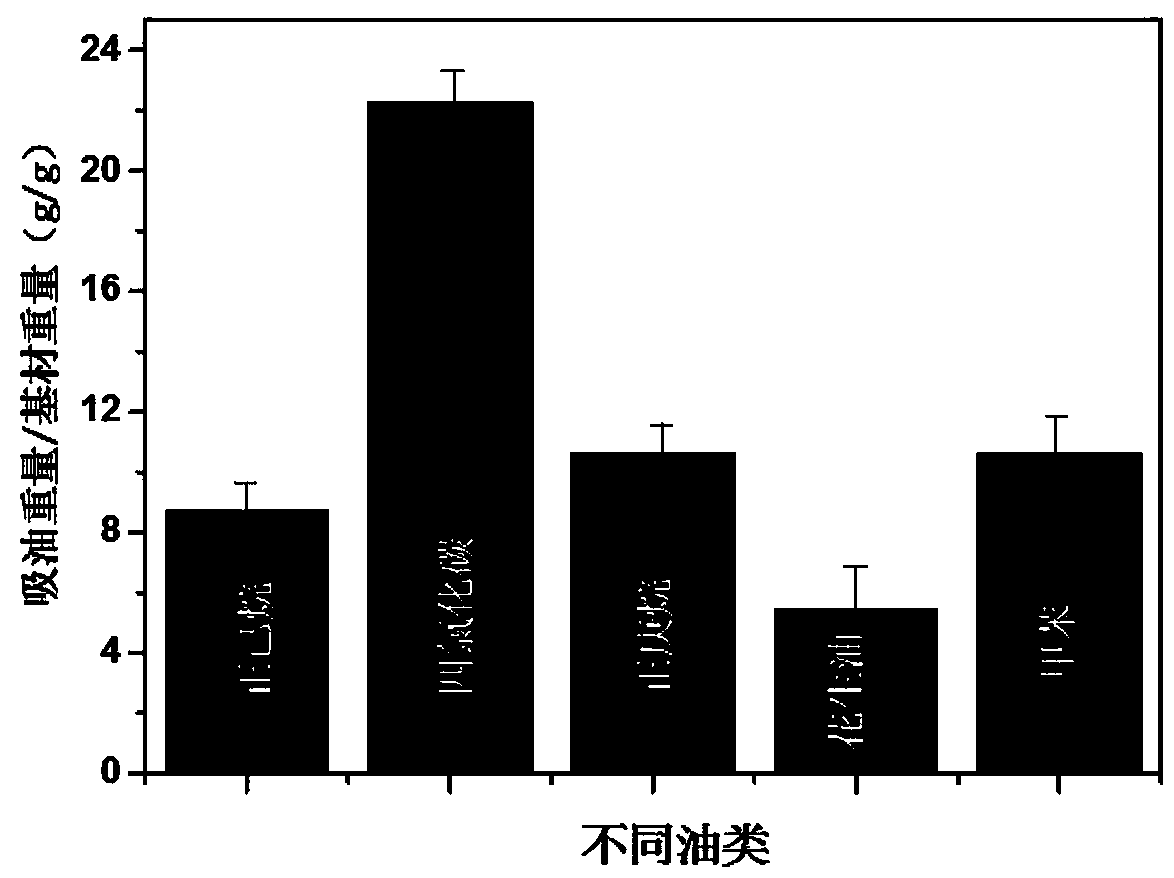

Super-hydrophobic oil-water separation material based on procyanidine modified shaddock peels and preparation method thereof

A technology for proanthocyanidins and separation materials, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process, high cost, unsuitable for industrial production and application, and achieve simple preparation process, easy operation and environmental protection The effect of green preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Wash the grapefruit peel, boil it for 2 hours at 100°C, then wash it with water and set aside;

[0038] (2) Dissolving procyanidins in water, adding tris(hydroxymethyl)aminomethane to adjust pH to 8.5, to obtain a procyanidin solution with a mass percentage of procyanidins of 1%; dispersing octadecylamine in water to obtain a mass percentage of octadecylamine Aqueous dispersion liquid containing amino hydrophobic modifier with a content of 3%;

[0039](3) soaking the pomelo peel treated in step (1) in the proanthocyanidin solution for 1 hour, taking it out and drying it in a drying oven at 80°C for 2 hours; this process is repeated 5 times to obtain the proanthocyanidin-modified pomelo peel;

[0040] (4) Immerse the proanthocyanidin-modified grapefruit peel obtained in step (3) in an aqueous dispersion of an amino-containing hydrophobic modifier, react at 60° C. for 12 hours, take it out, and dry it in a drying oven at 80° C. for 4 hours to obtain Superhydrophobic ...

Embodiment 2

[0045] (1) Wash the pomelo peels, boil them in water for 2 hours at 94°C, wash them with water, and set aside for later use;

[0046] (2) Dissolving procyanidins in water, adding sodium hydroxide to adjust pH to 9.0, to obtain a procyanidin solution with a mass percentage of procyanidins of 3%; dispersing amino silicone oil (average molecular weight of 50,000, ammonia value of 0.3) in water, The mass percentage of amino silicone oil obtained is 1% amino-containing hydrophobic modifier aqueous dispersion;

[0047] (3) soak the pomelo peel treated in step (1) in the proanthocyanidin solution for 1 hour, take it out and dry it in a drying oven at 80°C for 3 hours; repeat this process 3 times to obtain the proanthocyanidin-modified pomelo peel;

[0048] (4) Immerse the proanthocyanidin-modified grapefruit peel obtained in step (3) in an aqueous dispersion of an amino-containing hydrophobic modifier, react at 70° C. for 8 hours, take it out, and dry it in a drying oven at 100° C. f...

Embodiment 3

[0053] (1) Wash the grapefruit peel, boil it for 2 hours at 90°C, and then wash it with water for later use;

[0054] (2) Dissolving proanthocyanidins in water, adding sodium hydroxide to adjust pH to 8.8, to obtain a procyanidin solution with a mass percentage of procyanidins of 5%; dispersing hexadecylamine in water to obtain a mass percentage of hexadecylamine: 0.5% aqueous dispersion of amino hydrophobic modifier;

[0055] (3) soak the pomelo peel treated in step (1) in the proanthocyanidin solution for 0.5 hour, take it out and dry it in a drying oven at 100°C for 2 hours; repeat this process 3 times to obtain the proanthocyanidin-modified pomelo peel;

[0056] (4) Immerse the proanthocyanidin-modified grapefruit peel obtained in step (3) in an aqueous dispersion containing an amino-containing hydrophobic modifier, react at 80°C for 3 hours, take it out, and dry it in a 90°C drying oven for 2 hours to obtain Superhydrophobic oil-water separation material based on proanth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com