High-purity tripolyglycerol monolaurate and preparation method and application thereof

A technology of tripolyglycerol and laurate, which is applied in the preparation, application and ether preparation of carboxylate, can solve the problems of difficulty in obtaining high-purity products, unsuitable food additives for purified products, and limited bacteriostatic activity, etc. The effect of rapid high-purity large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

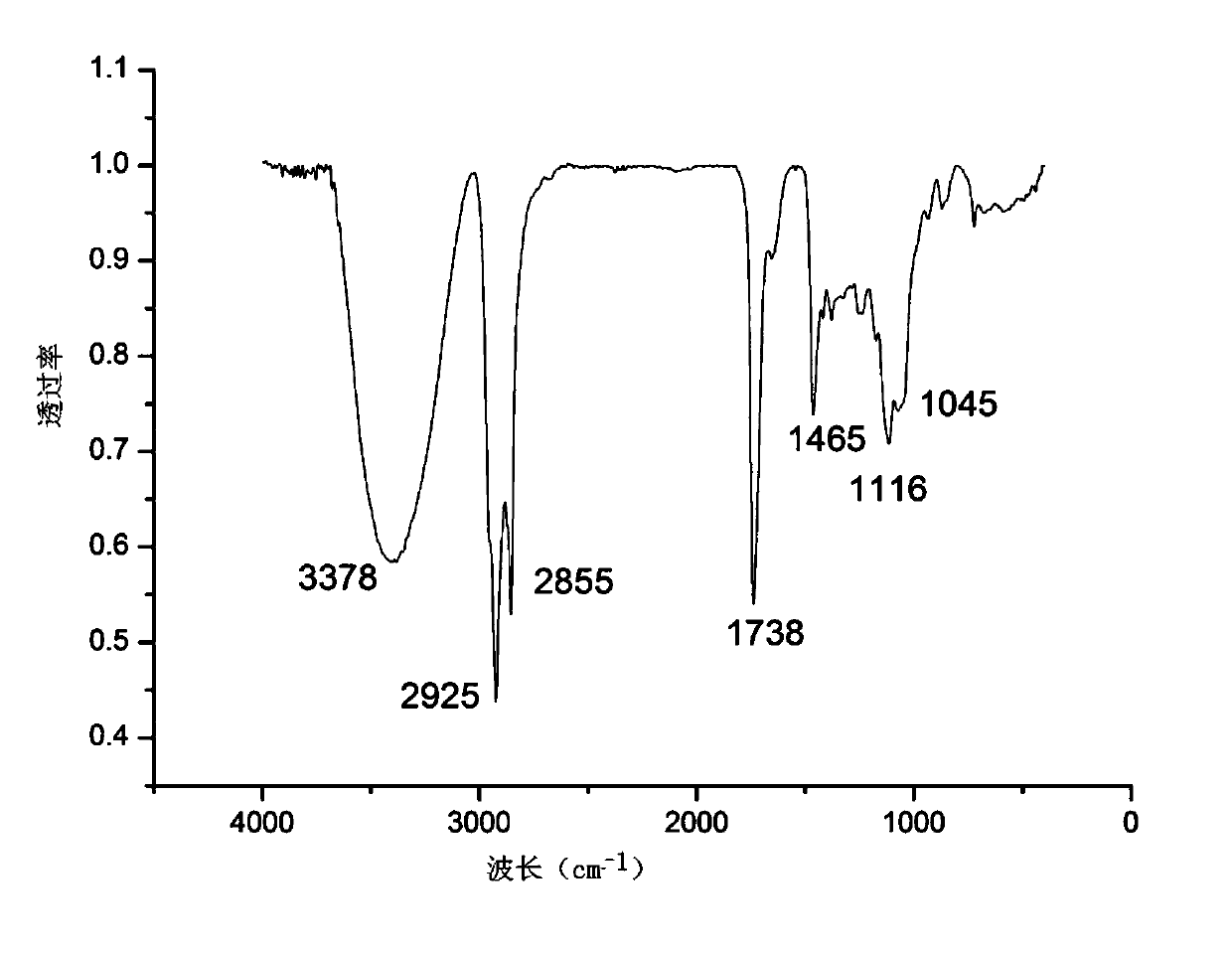

[0050]Embodiment 1: the preparation of tripolyglycerol monolaurate

[0051] A preparation method of high-purity triglycerol monolaurate, comprising the following steps:

[0052] (1) Synthesis of polyglycerol: Add 1 kg of glycerol into a 2L three-necked flask, and add 2% solid NaOH as a catalyst in proportion to mass; protect with nitrogen, react at 250°C for 8 hours; (磷酸) :n (NaOH) =1:1.5 Add phosphoric acid to neutralize the alkaline catalyst, then add 5 times the mass of absolute ethanol for desalination, remove phosphate by vacuum filtration, and then distill under reduced pressure to remove ethanol and water to obtain polyglycerol;

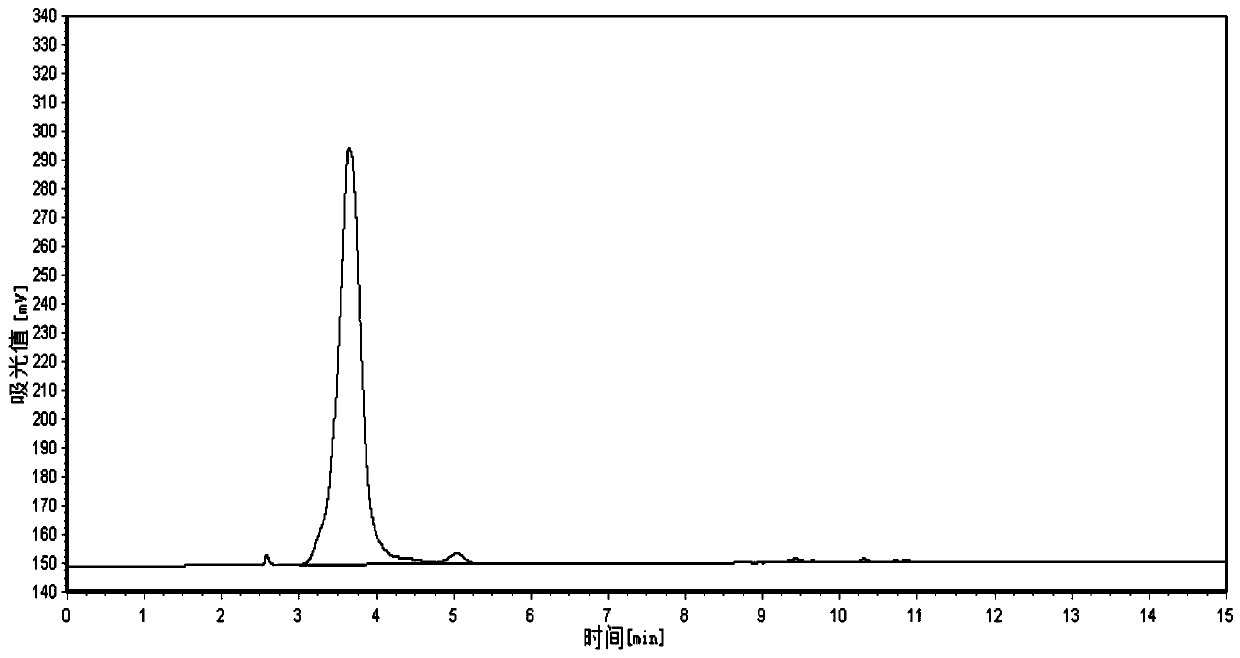

[0053] (2) Purification of triglycerol: the polyglycerol product synthesized in step (1) is subjected to secondary molecular distillation and purification; wherein, the parameters of primary molecular distillation are: distillation temperature 150°C, condensation temperature 60°C, pressure 20Pa, speed of scraping film 150rpm, collect the hea...

Embodiment 2

[0056] Embodiment 2: the preparation of tripolyglycerol monolaurate

[0057] A preparation method of high-purity triglycerol monolaurate, comprising the following steps:

[0058] (1) Synthesis of polyglycerol: Add 1 kg of glycerol into a 2L three-necked flask, and add 2% solid NaOH as a catalyst in proportion to mass; protect with nitrogen, react at 260°C for 4 hours; (磷酸) :n (NaOH) =1:1.5 Add phosphoric acid to neutralize the alkaline catalyst, then add 5 times the mass of absolute ethanol for desalination, remove phosphate by vacuum filtration, and then distill under reduced pressure to remove ethanol and water to obtain polyglycerol;

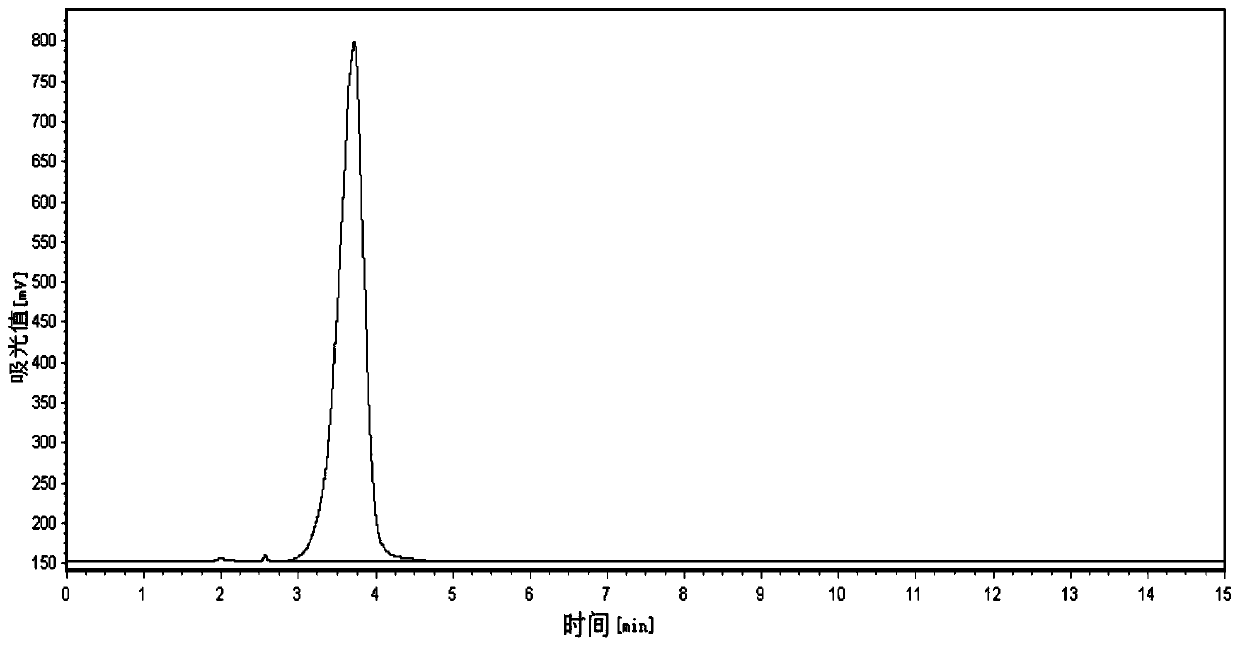

[0059] (2) Purification of triglycerol: The polyglycerol product synthesized in step (1) is subjected to secondary molecular distillation and purification; wherein, the parameters of primary molecular distillation are: distillation temperature 170°C, condensation temperature 50°C, pressure 50Pa, speed of scraping film 200rpm, collect the he...

Embodiment 3

[0062] Embodiment 3: the preparation of tripolyglycerol monolaurate

[0063] A preparation method of high-purity triglycerol monolaurate, comprising the following steps:

[0064] (1) Synthesis of polyglycerol: Add 1 kg of glycerol into a 2L three-necked flask, and add 2% solid NaOH as a catalyst in proportion to the mass; protect with nitrogen, react at 280°C for 2 hours; according to n (phosphoric acid): n (NaOH) = 1: 1.5 Add phosphoric acid to neutralize the alkaline catalyst, then add 5 times the mass of absolute ethanol for desalination, remove phosphate by vacuum filtration, and then remove ethanol and water by vacuum distillation to obtain polyglycerol;

[0065] (2) Purification of triglycerol: The polyglycerol product synthesized in step (1) is subjected to secondary molecular distillation and purification; wherein, the parameters of primary molecular distillation are: distillation temperature 150°C, condensation temperature 60°C, pressure 60Pa, speed of scraping film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com