Efficient and uniform heat conduction polymer-based heat conduction material and preparation method thereof

A technology of heat-conducting materials and polymers, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of thermal conductivity decline, uneven heat conduction, etc., and achieve high thermal conductivity, fast and uniform heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

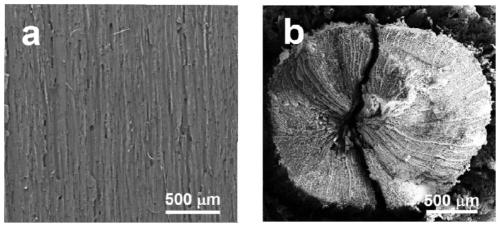

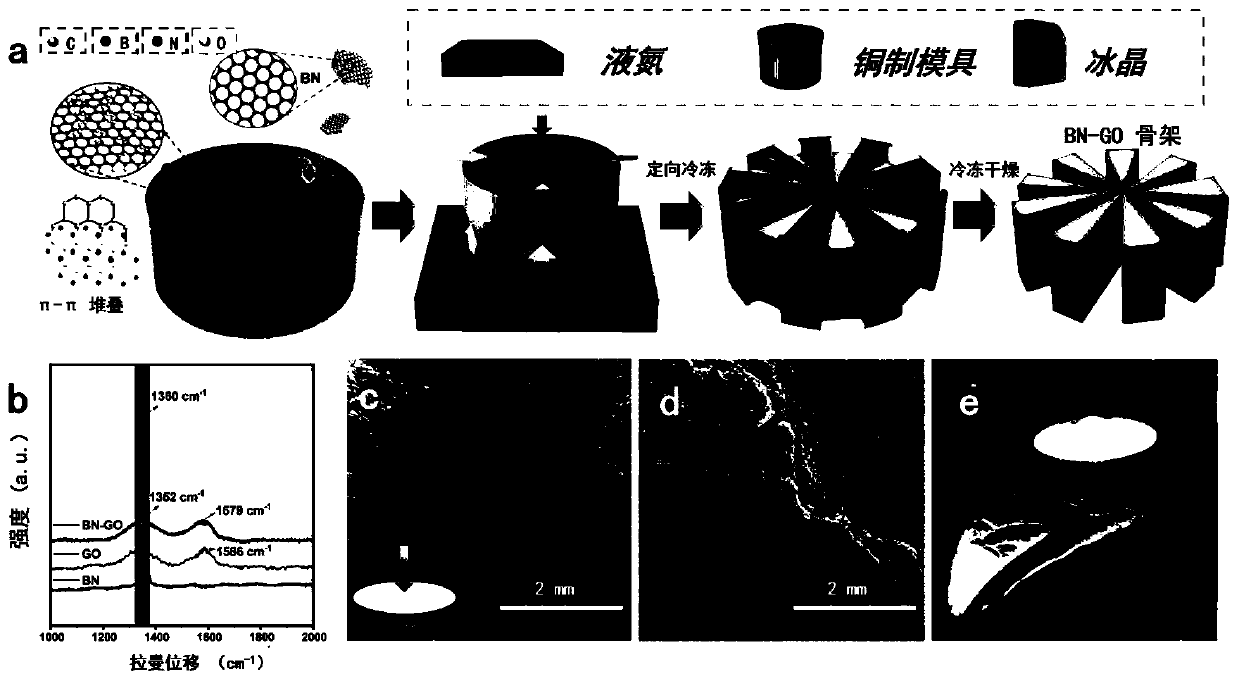

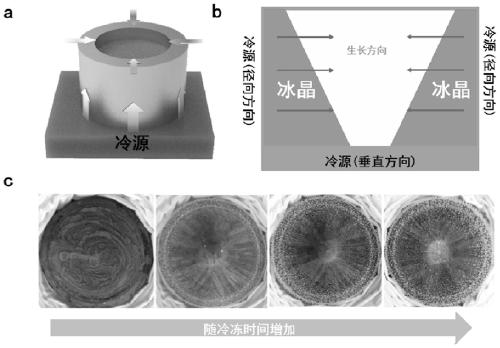

[0029] Mold preparation reference [Wang C, Chen X, Wang B, et al. Freeze-Casting Producesa Graphene Oxide Aerogel with a Radial and Centrosymmetric Structure[J].ACSNano,2018,12(6).5816-5825].

[0030] In the following examples, the mold used is a copper rod with a length of 25 cm and a diameter of 3 cm. There is a groove at the top with a diameter of 2.54 cm and a depth of 1.5 cm, and the bottom of the groove is cushioned with a thickness of 1 cm. of silicone rubber.

Embodiment 1

[0031] Embodiment 1: Preparation of polyethylene glycol / boron nitride (PEG / BN) composite thermally conductive material with multi-oriented structure:

[0032] Step 1: Preparation of Graphene Oxide (GO)

[0033] Add 2g of graphite powder and 1g of sodium nitrate into a 500ml beaker, add 50ml of concentrated sulfuric acid in an ice bath (0°C) and mix well. Under magnetic stirring, 6 g of potassium permanganate was added to the above mixing system in 6 times within 1 h, and reacted at 0° C. for 2 h. After the reaction, the ice-water bath was removed, and the temperature of the system was gradually raised to 35° C., and the reaction was carried out for 30 minutes. Afterwards, 100ml of deionized water was slowly added, and after no violent exotherm, the temperature was gradually raised to 98° C., and reacted for 3 hours. After the reaction was completed, when the temperature of the system was lowered to room temperature, 50 ml of 30 wt % hydrogen peroxide solution was added. The...

Embodiment 2

[0040] Embodiment 2: Preparation of polyethylene glycol / graphene (PEG / Graphene) composite thermally conductive material with multi-orientation structure:

[0041] Step 1: Preparation of Graphene Oxide (GO)

[0042] Add 2g of graphite powder and 1g of sodium nitrate into a 500ml beaker, add 50ml of concentrated sulfuric acid in an ice bath (0°C) and mix well. Under magnetic stirring, 6 g of potassium permanganate was added to the above mixing system in 6 times within 1 h, and reacted at 0° C. for 2 h. After the reaction, the ice-water bath was removed, and the temperature of the system was gradually raised to 35° C., and the reaction was carried out for 30 minutes. Afterwards, 100ml of deionized water was slowly added, and after no violent exotherm, the temperature was gradually raised to 98° C., and reacted for 3 hours. After the reaction was completed, when the temperature of the system was lowered to room temperature, 50 ml of 30 wt % hydrogen peroxide solution was added. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com